Microsoft Dynamics GP 2013

New Features

Module 2: Distributions

Released V1.0 Released: October 30, 2012

Conditions and Terms of Use

This training package content is proprietary and confidential, and is intended only for users described in

the training materials. This content and information is provided to you under a Non-Disclosure Agreement

and cannot be distributed. Copying or disclosing all or any portion of the content and/or information

included in this package is strictly prohibited.

The contents of this package are for informational and training purposes only and are provided "as is"

without warranty of any kind, whether express or implied, including but not limited to the implied

warranties of merchantability, fitness for a particular purpose, and non-infringement.

Training package content, including URL and other Internet Web site references, is subject to change

without notice. Because Microsoft must respond to changing market conditions, the content should not

be interpreted to be a commitment on the part of Microsoft, and Microsoft cannot guarantee the

accuracy of any information presented after the date of publication. Unless otherwise noted, the

companies, organizations, products, domain names, e-mail addresses, logos, people, places, and events

depicted herein are fictitious, and no association with any real company, organization, product, domain

name, e-mail address, logo, person, place, or event is intended or should be inferred.

Copyright and Trademarks

© 2012 Microsoft Corporation. All rights reserved.

Microsoft may have patents, patent applications, trademarks, copyrights, or other intellectual property

rights covering subject matter in this document. Except as expressly provided in written license

agreement from Microsoft, the furnishing of this document does not give you any license to these

patents, trademarks, copyrights, or other intellectual property.

Complying with all applicable copyright laws is the responsibility of the user. Without limiting the rights

under copyright, no part of this document may be reproduced, stored in or introduced into a retrieval

system, or transmitted in any form or by any means (electronic, mechanical, photocopying, recording, or

otherwise), or for any purpose, without the express written permission of Microsoft Corporation.

For more information, see Use of Microsoft Copyrighted Content at

http://www.microsoft.com/about/legal/permissions/

Microsoft®, Internet Explorer®, and Windows® are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries. Microsoft products mentioned herein

may be either registered trademarks or trademarks of Microsoft Corporation in the United States and/or

other countries. All other trademarks are property of their respective owners.

About the Authors

Author:

Angela Ebensteiner

Bio:

Angela is a Technical Lead with 15 years of experience supporting the Microsoft

Dynamics GP product. Her primary focus is the Distribution and Manufacturing

modules. She also has experience with Financials and Product Accounting.

Author:

Pam Peterson

Bio:

Pam is a Senior Technical Lead with 18 years of experience supporting Microsoft

Dynamics products. Her focus is on Distribution and Project Accounting modules, but

she has also worked with Financials and Field Service.

Table of Contents

MODULE #1: INVENTORY ....................................................................................................................................... 1

LESSON #1: INACTIVATING ITEMS ............................................................................................................................... 2

Inactivating Items .................................................................................................................................................. 2

Changes to Windows and Reports .................................................................................................................... 2

Functionality Described .................................................................................................................................... 4

Try This: Inactivate a Service item and enter a transaction .............................................................................. 7

Lesson Review ....................................................................................................................................................... 8

LESSON #2: REASON CODES FOR INVENTORY TRANSACTIONS ........................................................................................... 9

Reason Codes ........................................................................................................................................................ 9

New: Reason Code Setup window .................................................................................................................... 9

Functionality Described .................................................................................................................................. 11

Changes to existing reports............................................................................................................................. 13

Changes to Microsoft Dynamics GP tables ..................................................................................................... 14

Try This: Create and use a Reason Code ......................................................................................................... 14

Lesson Review ..................................................................................................................................................... 15

LESSON #3: MAINTAIN BIN TRANSFER HISTORY .......................................................................................................... 16

Bin Transfer History ............................................................................................................................................. 16

Changes to Windows ...................................................................................................................................... 16

Additions and changes to Microsoft Dynamics GP tables ............................................................................... 18

New Inquiry Windows ..................................................................................................................................... 19

New Removal Utility ....................................................................................................................................... 21

Try This: Transfer an item to a different bin and review the result ................................................................ 23

Lesson Review ..................................................................................................................................................... 23

LESSON #4: RECONCILE INVENTORY WITH GENERAL LEDGER .......................................................................................... 24

Reconcile to GL .................................................................................................................................................... 24

Reconcile to GL window .................................................................................................................................. 25

Functionality Described .................................................................................................................................. 26

Excel Output .................................................................................................................................................... 28

Explanation of financial fields ......................................................................................................................... 29

Lesson Review ..................................................................................................................................................... 30

LESSON #5: STANDARD COST ADJUSTMENT ............................................................................................................... 31

Standard Cost Adjustment .................................................................................................................................. 31

Changes to Windows ...................................................................................................................................... 31

Changes to Reports ......................................................................................................................................... 36

Try This: Change the standard cost of your item ............................................................................................ 37

Lesson Review ..................................................................................................................................................... 38

LESSON #6: INACTIVATE SITES ................................................................................................................................. 39

Inactivate Sites and Item/Site combinations ....................................................................................................... 39

Changes to Windows and Reports .................................................................................................................. 39

Functionality Described .................................................................................................................................. 41

Lesson Review ..................................................................................................................................................... 42

LESSON #7: MULTI-SELECT SERIAL NUMBERS .............................................................................................................. 43

Multi-select serial numbers ................................................................................................................................. 43

Feature Described ........................................................................................................................................... 43

Changes to Windows ...................................................................................................................................... 44

Lesson Review ..................................................................................................................................................... 46

MODULE #2: SALES ORDER PROCESSING ............................................................................................................. 47

LESSON #1: SHIP-TO ADDRESS WITH A DIFFERENT COMPANY NAME ................................................................................. 48

Ship-to Addresses with a different company name ............................................................................................ 48

Functionality Described .................................................................................................................................. 48

Changes to Windows ...................................................................................................................................... 55

Changes to Reports ......................................................................................................................................... 60

How the Copy functionality is affected ........................................................................................................... 61

Try This: Enter and print a Sales Order with 2 lines each shipped to a different location .............................. 62

Lesson Review ..................................................................................................................................................... 63

LESSON #2: COMBINED INVOICE .............................................................................................................................. 64

Combined Invoice ................................................................................................................................................ 64

Changes to Sales Bulk Confirmation window .................................................................................................. 64

New: Sales Bulk Confirmation - Combined Invoice report .............................................................................. 65

Functionality explained ................................................................................................................................... 66

Reviewing the document ................................................................................................................................ 67

Try This: Combine 2 orders into 1 invoice ....................................................................................................... 68

Lesson Review ..................................................................................................................................................... 68

LESSON #3: SUGGESTED SELLING ............................................................................................................................. 69

Link Items for Suggested Sales ............................................................................................................................ 69

New: Suggest Sales Item Maintenance window ............................................................................................. 69

New: Suggest Sales Item Entry window .......................................................................................................... 71

Functionality Described .................................................................................................................................. 71

Try This: Add a companion item to main item and sell it together................................................................. 72

Lesson Review ..................................................................................................................................................... 72

LESSON #4: NEW WORD TEMPLATES ........................................................................................................................ 73

New Word Templates .......................................................................................................................................... 73

Changes to the following areas of GP allow for the addition of these templates .......................................... 73

Functionality Described .................................................................................................................................. 75

Lesson Review ..................................................................................................................................................... 76

LESSON #5: E-MAIL INDICATORS .............................................................................................................................. 77

Email Indicator .................................................................................................................................................... 77

Changes to windows with addition of e-mail indicators ................................................................................. 77

Functionality described ................................................................................................................................... 78

Lesson Review ..................................................................................................................................................... 79

MODULE #3: PURCHASE ORDER PROCESSING ...................................................................................................... 80

LESSON #1: PREPAYMENT IN PURCHASE ORDER .......................................................................................................... 81

Prepayment in Purchase Order ........................................................................................................................... 81

Changes to Windows ...................................................................................................................................... 82

Functionality Described .................................................................................................................................. 92

Changes to Reports ......................................................................................................................................... 97

Try This: Enter a PO with a prepayment and process that payment .............................................................. 98

Lesson Review ..................................................................................................................................................... 99

LESSON #2: PO TOLERANCE ................................................................................................................................. 100

PO Tolerance ..................................................................................................................................................... 100

Changes to Windows and Reports ................................................................................................................ 100

Functionality Described ................................................................................................................................ 103

Try This: Enter a Tolerance Shortage Percentage and do a transaction ....................................................... 109

Try This: Enter a Tolerance Overage Percentage and enter a transaction.................................................... 110

Lesson Review ................................................................................................................................................... 111

LESSON #3: TRACKING SERIAL/LOT NUMBERS .......................................................................................................... 112

Tracking Serial and Lot Numbers on drop-ship POs .......................................................................................... 112

Changes to Windows .................................................................................................................................... 112

Functionality Described ................................................................................................................................ 116

Changes to Reports ....................................................................................................................................... 118

Try This: Track a serial number for a drop-ship PO ....................................................................................... 119

Lesson Review ................................................................................................................................................... 119

LESSON #4: PREVENT PURCHASE ORDER CLOSE ........................................................................................................ 120

Prevent closing a PO before it is fully invoiced ................................................................................................. 120

Changes to Windows .................................................................................................................................... 120

Functionality Described ................................................................................................................................ 121

Try This: Attempt to close a PO short ........................................................................................................... 123

Lesson Review ................................................................................................................................................... 123

MODULE #4: MANUFACTURING ........................................................................................................................ 124

LESSON #1: PRINT FROM PICKLIST SHORTAGES INQUIRY.............................................................................................. 125

Print from the Picklist Shortages Inquiry window ............................................................................................. 125

Feature Described ......................................................................................................................................... 125

Lesson Review ................................................................................................................................................... 128

Released V1.0 Microsoft Dynamics GP 2013 New Features

1

Module #1: Inventory

This module introduces the new enhancements to Inventory Control in the Distribution

series of Microsoft Dynamics GP 2013.

Before You Begin

Before starting this module, you should:

Be familiar with adding Inventory items

Have experience entering basic Sales Order Processing transactions

Understand basic multi-bin functionality

Understand basic Purchase Order Processing functionality and how to enter

transactions

Have access to a Microsoft Dynamics GP 2013 installation.

What You Will Learn

After completing this module, you will be able to:

Describe the changes related to the Item Maintenance window and how it impacts

the distribution modules

Explain how to use Reason Codes to easily track movement in your inventory

Manage your bin to bin transfers and report on their history

Troubleshoot Inventory and General Ledger reconciliation issues

Explain how to change the standard cost of an item

Maintain inventory sites by inactivating them

Describe how to select multiple serial numbers at one time for use on a transaction

Module 2: Distributions Released V1.0

2

Lesson #1: Inactivating Items

This lesson explains the additional functionality added to the Item Maintenance window.

This allows users to inactivate any item type to prevent further sale and purchase of the

item.

What You Will Learn

After completing this lesson, you will:

Understand how to inactivate an item

Know what checks are completed when inactivating an item

Understand how inactivating affects the processing of transactions

Inactivating Items

An Inactive checkbox is added to the Item Maintenance window to allow you to inactivate

an item permanently or temporarily. This feature adds flexibility by creating the ability to

change an item type from active to inactive, which will stop or warn about the sale,

purchase and new processing of the item while retaining item history.

Note:

In Microsoft Dynamics GP 2010 and previous versions, you have the ability to change a

Sales Inventory Item Type to a Discontinued Item Type in order to stop the Sale and

Purchase of an item. To stop the Sale or Purchase on all other Item Types (e.g. Kit,

Miscellaneous, Service, and Flat Fee) you would have to delete all inventory history for

the item, and then delete the item itself thereby losing all visibility to historical data.

Changes to Windows and Reports

Item Maintenance window

A new Inactive checkbox is available next to the Item Number note field in Item

Maintenance. This checkbox is available to be selected or unselected at any time. To open

Item Maintenance: on the Cards menu, point to Inventory, and then click Item.

Released V1.0 Microsoft Dynamics GP 2013 New Features

3

Figure 1: Item Maintenance

Note:

When you click to mark the Inactive checkbox, you will receive the warning "Inactivating

this item will exclude it from being planned in the Item Resource Planning Maintenance

window." Since you no longer want to purchase this inactive item, you will not be able

to select it in the Item Resource Planning Maintenance window. Click to unmark the

Inactive checkbox, to be able to purchase the item again.

Item Lookup window

When you select the Item Number lookup, there is now an Advanced Lookup option to

"Exclude Inactive Items." When this is chosen, items marked as inactive will not appear in

the item listing.

Figure 2: Item lookup

Module 2: Distributions Released V1.0

4

Note:

Users have the ability to Exclude Inactive Items in the Advanced Lookup option and "Set

as Default View." This functionality excludes those items from any Item number lookup

throughout Microsoft Dynamics GP windows.

Inventory Item Report Options window

The Inventory Item Report Option window now includes an Inactive Items checkbox. This

functionality lets you decide if you want to include or exclude Inactive items from printing

on the Detailed Item List Report. To print an inventory item report on the Reports menu,

point to Inventory, and then click Item.

Item List View

The item List View can now filter on Inactive items.

Figure 3: Item List

Functionality Described

When you inactive any item, it will prevent the sale and purchase of the item. This can be

done temporarily or permanently. There are validations and checks that occur in the

software when you mark or unmark this option.

Released V1.0 Microsoft Dynamics GP 2013 New Features

5

Selecting the checkbox

When you select the Inactive checkbox in the Item Maintenance window for an item,

verification is done to determine whether the item exists in the following locations. When

this process is complete, a warning message will display.

a. Active Kit

i. If the item is on an active Kit, you will receive a warning message "This

item is part of a kit and cannot be marked inactive." You will need to

remove the item from the kit before continuing.

b. Active Inventory Bill of Material (BOM)

i. If the item is on an active BOM, you will receive a warning message "This

item is part of an active assembly and cannot be marked Inactive." You

will need to remove the item from the BOM before continuing.

Note:

If you use Manufacturing, the system checks the Calculate MRP for this Item/Site as well

as the Order Policy when you inactivate an item. The Calculate in MRP for this item/site

field will be unmarked and the Order Policy will be set to "Not Planned" when you

inactivate the item. If you decide to activate the item again, these fields will need to be

reset.

If an item is inactive and you try to select the item in the Item Resource Planning

window, you will receive the message "This item is inactive, Activate the item or enter

another item."

Note:

If an item is on a Manufacturing BOM (All types) or a non-closed Manufacturing picklist,

the order/BOM must be processed or changed prior to making the component item

inactive.

Unselecting the checkbox

When you click to umark the Inactivate checkbox in the Item Maintenance window for a Kit

or Inventory BOM, all components assigned to it will be verified. If one of the components is

in an inactive state, you will receive the following error "This kit, assembly, or order contains

one or more inactive components. You must activate the component before you can activate

the kit, assembly, or order."

Module 2: Distributions Released V1.0

6

Affects to documents

Adding items to documents:

In some instances, inactive items can be used on new documents. In other cases, it is not

allowed. Below describes each instance.

Documents allowed to have inactive items added are as follows:

a. Sales Order Processing Return

b. Inventory Transfers

c. Inventory Variances (positive and negative)

d. Inventory decrease adjustments

e. Item Bin Transfer Entry

f. Shipment or Shipment/Invoice

Note:

You receive the following warning message when you add an inactive item to the above

documents: "The item selected is inactive."

Users can bypass the message and continue processing.

g. In-Transit Transfers

h. Project Accounting Inventory Transfers

Documents not allowed to have an inactive item added are as follows:

a. Sales Order Processing documents (Order, Invoice, Quote, Back Order)

b. Purchase Order Processing (Purchase Orders)

c. Invoicing Invoice

d. Manufacturing (all documents including adding an item to a BOM and BOM Mass

update)

Note:

You receive the warning message "This item is inactive. Activate the item or enter

another item" when you attempt to enter a transaction in the above windows for an

inactive item.

e. Inventory increase adjustments

Note:

An inventory increase adjustment is not allowed. You will receive a warning "You cannot

enter an increase adjustment for an inactive item."

Released V1.0 Microsoft Dynamics GP 2013 New Features

7

Existing Documents and Processes

1. If the item is inactivated while on an unposted transaction, that transaction will be

allowed to post. The only exception is on a Not Released BOM. When you change

the BOM from Not Released to Released and a component is inactive, the process

will stop and a warning message will occur: "This kit, assembly, or order contains one

or more inactive components. You must activate the components before you can

activate the kit, assembly, or order."

2. Quantities cannot be changed for inactive items on unposted documents. You will

receive the warning "The selected item is inactive. The quantity cannot be changed."

3. PO Generator will ignore inactive items and no PO will be created when demand

exists.

4. The charts below indicates if you can add an item onto an Active/Inactive Kit or

BOM

Type of item

Active Kit/BOM

Inactive Kit/BOM

Active Item

Yes

Yes

Inactive Item

No

Yes

Try This: Inactivate a Service item and enter a transaction

Take what you have learned and inactivate an item with history. Try to use it on a new sales

document.

1. Start by creating an inventory item with a Service Item Type in the Item

Maintenance window.

2. Enter and post an increase adjustment for the item for a quantity of 10.

3. Open Item Maintenance, click Inactivate, and then click Save.

4. Finish by trying to add the item to a new Sales Order Processing invoice.

You will receive a warning message "This item is inactive. Activate the item or enter another

item."

Module 2: Distributions Released V1.0

8

Lesson Review

Topics covered in this lesson include the following:

You can inactivate an item at any time by clicking the Inactive checkbox in Item

Maintenance

When an item is inactive, you are prevented from entering it on any Sales Order

Processing transactions that decrease the quantity.

Answer the following questions to confirm your understanding of lesson topics.

1. Can you inactivate an item when unposted transactions containing it exist?

Yes, you can inactivate the item and you will be able to post the transaction without warning

messages.

2. Are you able to enter a sales order for an inactive item?

No, you receive the message "The item is inactive. Activate the item or enter another item", and

are prevented from doing the transaction with that item.

Released V1.0 Microsoft Dynamics GP 2013 New Features

9

Lesson #2: Reason Codes for Inventory Transactions

This lesson explains the functionality of adding Reason Codes to inventory movement

transactions. Reason Codes are a tool you can use to provide insight into daily operations,

which will provide efficiencies and increase the return on your investment.

What You Will Learn

After completing this lesson, you will be able to:

Create and modify Reason Codes

Assign Reason Codes to transactions

Explain how the use of Reason Codes affects posting to General Ledger

Review Reason Code information on posted transactions

Reason Codes

Reason Codes are a means for you to enter additional data on your inventory transactions,

which allows greater visibility into the movement of your items. This feature allows for

trend analysis around this movement and allows you to control what GL posting account is

used based on the Reason Code selected.

New: Reason Code Setup window

Use this window to create or modify Reason Codes for moving inventory from one site to

another, one bin to another, or from or into your inventory. To access the Reason Code

Setup window on the Microsoft Dynamics GP menu, point to Tools, point to Setup, point

to Inventory, and then click Reason Code Setup.

Figure 4: Reason Code Setup

Module 2: Distributions Released V1.0

10

In Reason Code Setup, you can select which type of transactions you want the ability to use

the Reason Codes on. These include Inventory Adjustments, Variances, standard Transfers,

In-transit Transfers and Item Bin Transfers. You can select if the Reason Code is appropriate

for Increases, Decreases or both types of transactions.

When you click Adjustment or Variance as the Inventory Transaction, you are required to

enter an account for the Default Offset Account. This account will be used in place of the

account defined on the item or in Posting Setup. Assigning a specific account to a Reason

Code allows you to track account balances at a Reason Code level. For example for a Reason

Code you are using to track spoilage in your inventory, you may want to set up a General

Ledger account specifically for spoilage. This way you can review the balance of that

account in GL as well as report on it from a Reason Code perspective in Inventory. If you do

not enter a Default Offset Account, you will receive the message "A default offset account is

required when you select Variance or Adjustment."

Note:

If site substitutions are being used, those rules will be applied to the given Default

Offset Account.

Note:

The data represented in the Reason Code Setup window is stored in a new table called

Reason Code Setup (IV40300).

Note:

To have access to the Reason Code Setup window, you must be a part of either the Task

ADMIN_INV_001* or Task INQ_INV_002* task.

Reason Codes can be modified, inactivated or deleted at any time using this window. There

is no impact on existing unposted or historical transactions. When you inactivate a Reason

Code, you will receive the following message: "Inactivating this reason code will allow you to

finish processing any open transactions that contain it. You will no longer be able to assign it

to new transactions". This will let you know that existing unposted transactions can be

posted but you will not be able to use the Reason Code in the future.

Reason Codes are optional. Even when implemented they do not have to be assigned to

every transaction.

Released V1.0 Microsoft Dynamics GP 2013 New Features

11

Functionality Described

The ability to enter Reason Codes has been added to inventory transactions in order to have

better visibility into why stock is being moved.

Reason Codes can be entered for transactions entered in the following windows:

a. Item Transaction Entry

b. Item Transfer Entry

c. In-Transit Transfer Entry

d. Stock Count Entry

e. Item Bin Transfer Entry

Figure 5: Item Transaction Entry

When you create a new transaction, you can choose to enter an existing Reason Code or

create a new one at the time of transaction entry. When you use an existing Reason Code,

the rules applied during set up must be abided by. For example, if you selected "Decrease

Only" as the Types of Adjustment/Variance and only the Variance transaction type, you

will not be able to use that Reason Code for an increase transaction or in the Item Transfer

window. You will receive messages like "The selected reason code is not set up for this type of

transaction" and "The reason code selected does not allow increase variances."

Note:

Only Reason Codes applicable for the transaction type you are entering will show in the

Reason Code lookup window.

Module 2: Distributions Released V1.0

12

When you enter a Reason Code that does not exist, you will be prompted with the message

"This reason code doesn't exist. Do you want to add it?" When you click Add, you are brought

to the Reason Code Setup window to create the new Reason Code for your transaction.

Reason Codes can be viewed on transactions in the following windows:

a. In-Transit Transfer History Inquiry

b. Inventory Transaction Inquiry

c. Bin Transfer Inquiry

d. Item Bin Transfer Inquiry

e. Remove Bin Transfer History Preview

f. Item Transactions List

Note:

You can limit the data returned in the Item Transactions List by creating a Where clause

using the Reason Code filter.

Figure 6: Item Transactions List

Note:

You can use SmartList Builder to add the Reason Code field to inventory SmartLists. It

will not be there by default.

Reason Code Setup added as an Inventory Checklist item

The Reason Code Setup window has been added to the Inventory Setup Checklist. To open

the checklist on the Microsoft Dynamics GP menu point to Tools, point to Setup, and then

click Setup Checklist. Expand Inventory to display Reason Code Setup. As with any

checklist item, you can assign it to a user as a task or immediately open and complete it.

Released V1.0 Microsoft Dynamics GP 2013 New Features

13

Changes to existing reports

The Reason Code field has been added to the following reports so the value used on the

transaction will be displayed:

a. Inventory Adjustments Edit List

b. Transaction Posting Journal

c. Transaction Posting Journal - Reprint

d. Transfer Edit List

e. Transfer Posting Journal

f. Transfer Posting Journal - Reprint

g. Item Transaction Inquiry Report

h. Transaction History Report

Figure 7: Output of Transaction History Report

Module 2: Distributions Released V1.0

14

Changes to Microsoft Dynamics GP tables

The Reason Code data is stored in a field called Reason_Code. That field is present in the

following tables.

IV10001 - Inventory Transaction Amounts Work

IV10004 - Inventory Bin Quantity Transfer

IV10301 - Stock Count Line

IV30004 - Inventory Bin Quantity Transfer History (new to GP 2013)

IV30300 - Inventory Transaction History

IV30701 - Stock Count Line History

IV40300 - Reason Code Setup (new to GP 2013)

SVC00701 - Service Transfer Line Detail

SVC30701 - Service Transfer Line Detail History

Try This: Create and use a Reason Code

Take what you have learned in this lesson, and create a new Reason Code on the fly during

transaction entry and review the data.

1. In the Item Transaction Entry window, create a new Variance transaction for item

128 SDRAM.

2. In the Reason Code field, enter BROKEN.

3. When you are prompted with the message: "This reason code doesn't exist. Do you

want to add it?” click Add.

4. In the Reason Code Setup window, enter the Description Broken Item.

5. Click to mark Variance to use this Reason Code on Variance transactions.

6. Click to mark Decrease Only in the Type of Adjustments/Variances field.

7. In the Default Offset Account field, enter 000-1312- 00.

8. Click Save, and close the window.

9. In Item Transaction Entry, finish your transaction by entering a Quantity of -1 and

the Site of North.

10. Click Post and print the Transaction Posting Journal to screen to review the Reason

Code data and accounts used.

Released V1.0 Microsoft Dynamics GP 2013 New Features

15

Lesson Review

Topics covered in this lesson include the following:

Reason Codes can be used on inventory adjustments and inventory transfers and stock

counts. This allows you more information about the movement of your inventory.

When you use a Reason Code on a transaction, the GL posting account will pull from

Reason Code Setup.

Answer the following questions to confirm your understanding of lesson topics.

1. Can a Reason Code be entered when you sell an item on a Sales Order Processing

invoice?

No. Reason Codes can only be entered on Inventory transactions.

2. Can Reason Codes be set up to only be used with certain types of transactions?

Yes. When you set up the Reason Code, you decide which types of transactions it can be used

on. It will not appear in the Reason Code lookup on a transaction it is not set up for.

Module 2: Distributions Released V1.0

16

Lesson #3: Maintain Bin Transfer History

This lesson explains the additional functionality added to the Multi-bin feature, which

allows you the ability to maintain and view bin transfer history, and track reason codes for

bin movement.

What You Will Learn

After completing this lesson, you will:

Understand how to assign the document number for bin transfers.

Be able to enter a bin transfer transaction.

Know where to review bin transfer history information.

Know how to remove bin transfer history.

Bin Transfer History

The ability to track the history of what bin is used when you transfer between bins is

desired for better inventory control. On previous versions of Microsoft Dynamics GP, you

could transfer inventory quantities between bins. However, the history of those

transactions was not maintained without a customization. Now there is a new table called

Inventory Bin Quantity Transfer History (IV30004) that stores the history of your bin

transfer transactions.

Note:

This feature replaces the need for the Bin Transfer Tracking tool that was previously sold

as a customization.

Changes to Windows

Inventory Control Setup window

A new field for Bin Transfer has been added to the Next Document Number area in

the Inventory Control Setup window. Use this field to enter the number that will be

used for the next Bin Transfer transaction. This field will only be enabled when the

Enable Multiple Bins field is marked. To open Inventory Control Setup on the

Microsoft Dynamics GP menu point to Tools, point to Setup, point to Inventory, and

then click Inventory Control.

Released V1.0 Microsoft Dynamics GP 2013 New Features

17

Figure 8: Inventory Control Setup

Item Bin Transfer Entry window

Four new fields have been added to the Item Bin Transfer Entry window. To open Item

Bin Transfer Entry on the Transactions menu, point to Inventory, and then click Bin

Transfer Entry.

Figure 9: Item Bin Transfer Entry

A display only field of Document Type has been added to the Item Bin Transfer Entry

window. This is always populated with the words "Bin Transfer."

The Doc. Number field is automatically populated from the Next Document Number for

Bin Transfer from Inventory Control Setup. You can change this number but

duplicate numbers cannot be used.

Module 2: Distributions Released V1.0

18

Note:

You can enter a document level note by clicking the Note Icon by the Doc. Number field.

The Date field is populated with the current User Date and can be changed.

The Reason Code field is an optional field that you use to enter and track the reason for

which the bin transfer is taking place. For more information about the Reason Code

functionality, which was added in Microsoft Dynamics GP 2013, see Lesson #2.

Note:

If you attempt to open the Item Bin Transfer Entry window prior to populating the Bin

Transfer number, you will receive the message "The next document number could not be

displayed, please check the Inventory Control Setup window."

Additions and changes to Microsoft Dynamics GP tables

To accommodate this new functionality, changes were made to the existing Inventory

Transaction Amount Work table and a new table called Inventory Bin Quantity Transfer

History was added.

Inventory Transaction Amounts Work - IV10001.

The additional fields added to the IV10001 table are as follows:

DOCTYPE

Bin_XFer_Date

Bin_XFer_Doc_Number

NOTEINDX

Reason_Code

Inventory Bin Quantity Transfer History - IV30004.

The new table of IV30004 is used to store the history of the bin transfer transaction. New

bin transfers on Microsoft Dynamics GP 2013 will write to this table when you click

Transfer in the Item Bin Transfer Entry window.

Released V1.0 Microsoft Dynamics GP 2013 New Features

19

New Inquiry Windows

Several new inquiry windows were added to provide visibility into the historical bin

transfer transactions.

New: Item Bin Transfer Inquiry window

To view processed bin transfers, you can use the Item Bin Transfer Inquiry window. To

open this window on the Inquiry menu, point to Inventory, and then click Item Bin

Transfer. Use the lookup on Doc. Number, or enter the number associated with the

transfer you would like to review. Since this is a processed transaction, it will be read only

and no changes can be made.

This window pulls data from the new Inventory Bin Quantity Transfer History (IV30004)

table.

Figure 10: Item Bin Transfer Inquiry

Note:

To have access to the Item Bin Transfer Inquiry window you must be a part of the Task

INQ_INV_002*.

Module 2: Distributions Released V1.0

20

Item Bin Transfer Serial Number Inquiry and Item Bin Transfer Lot Number Inquiry

window

If the selected document in the Item Bin Transfer Inquiry window is for a serialized or lot

numbered item, then the Serial/Lot button will be available. Click the button to open the

Item Bin Transfer Serial Number Inquiry window. This window allows you to view

which serial numbers that were transferred on this transaction. If a lot numbered item was

used for the transaction, then the Serial/Lot button will open the Item Bin Transfer Lot

Number Inquiry window to display the lot numbers that were transferred.

Figure 11: Item Bin Transfer Lot Number Inquiry

New: Bin Transfer Inquiry window

To view more than one bin transfer at a time, you can use the Bin Transfer Inquiry

window. To access this window from the Inquiry menu, point to Inventory, and then click

Bin Transfer.

Figure 12: Bin Transfer Inquiry

Released V1.0 Microsoft Dynamics GP 2013 New Features

21

If desired, you can enter ranges for the From Bin, To Bin, Reason Code, Doc. Number, Bin

Transfer Date and Item Number. You can also enter a specific Site. All of these fields are

optional and limit the data that will be returned. Click Redisplay after you enter your

desired parameters to return the matching data.

This window pulls data from the new Inventory Bin Quantity Transfer History table

(IV30004).

When you highlight a transaction and click on the Doc. Number drill back, the Item Bin

Transfer Inquiry window will open.

There is not a print option within this inquiry window, however if SQL Server Reporting

Services (SSRS) reports are deployed the Bin Transfer Inquiry report is available to be

printed from the Report Manager.

Note:

To have access to the Bin Transfer Inquiry window you must be a part of the Task

INQ_INV_002*.

New Removal Utility

To remove unwanted history of bin transfers, you can use the Remove Bin Transfer

History window.

Remove Bin Transfer History window

In the Remove Bin Transfer History window, you can enter a date in which all bin transfer

transactions prior to the given date will be removed from the Inventory Bin Quantity

Transfer History (IV30004) table. To open Remove Bin Transfer History on the Microsoft

Dynamics GP menu, point to Tools, point to Utilities, point to Inventory, and then click

Remove Bin Transfer History.

Figure 13: Remove Bin Transfer History

Module 2: Distributions Released V1.0

22

Note:

If the date you enter in the Include Bin Transfers Dated On or Before field is after the

current User Date, you will receive the message "Check and reenter the date." This

prevents the removal of more history than desired.

Click Preview to open the Remove Bin Transfer History Preview window and review the

documents that will be removed. If there are documents displayed that you do not want

removed, close the window and enter a different date in the Include Bin Transfers Dated

on or Before field.

Figure 14: Remove Bin Transfer History Preview

Click Remove to remove the bin transfer history transactions, which are dated on or before

the date specified from the Inventory Bin Quantity Transfer History (IV30004) table. Once

records are removed, you will no longer be able to view them using the inquiry windows.

No report is printed when you use this window.

Note:

Prior to using this window, it is recommended that users make a backup of your

company database. The backup can be restore data in the event of unexpected data

loss.

Note:

To have access to the Remove Bin Transfer History window you must be a part of the

Task ADMIN_INV_009*.

Released V1.0 Microsoft Dynamics GP 2013 New Features

23

Try This: Transfer an item to a different bin and review the result

Take what you have learned, create a bin to bin transfer, and review it after processing.

1. Verify in Inventory Control Setup that a document number has been entered for

Bin Transfer.

2. Use the Item Bin Transfer Entry window to transfer a quantity from one bin to

another. Note the document number used for the transfer.

3. Open the Bin Transfer Inquiry window, and click Redisplay.

4. Highlight the document you entered in Step 2 and click the Doc. Number drillback

to review the transaction in the Item Bin Transfer Inquiry.

Lesson Review

Topics covered in this lesson include the following:

A new table called Inventory Bin Quantity Transfer History (IV3004) has been added to

record the history of processed bin transfers so you can review these transfers at a

later date.

The Bin Transfer Inquiry window can be used to review a single or group of previous

bin transfers.

You can remove bin history using the Remove Bin Transfer History utility.

Answer the following questions to confirm your understanding of lesson topics.

1. Can reporting be done on the Bin Quantity Transfer History table to see previously

processed bin transfers?

Yes. Print the Bin Transfer Inquiry SSRS report to view historical information, or create your own

report using the IV30004 table.

2. How can bin history be removed?

Use the Remove Bin Transfer History window to remove all bin history prior to a specific date.

Module 2: Distributions Released V1.0

24

Lesson #4: Reconcile Inventory with General Ledger

This lesson introduces the Reconcile to General Ledger functionality that now includes

Inventory.

What You Will Learn

After completing this lesson, you will be able to:

Describe how and when to use the Reconcile to GL window with the Inventory module.

Understand that the Historical Inventory Trial Balance (HITB) needs to be activated to

use the feature.

Determine why a transaction shows under a certain section on the Excel spreadsheet

results.

Reconcile to GL

In the Reconcile to GL window, Inventory has been added to the list of modules available.

This new functionality will allow you to analyze differences in transaction information

between Inventory and General Ledger transactions. The Historical Inventory Trial Balance

(HITB) data is utilized in this process.

You would use this routine if you printed the HITB report for an account and compared it to

the account's balance in GL and found a difference. This routine would show the

transaction(s) that are not matched or potentially not matched between the two modules so

that you can investigate those transactions and determine why the discrepancy exists.

The results can be exported to Excel for analysis or saved to be reviewed at a later point.

Note:

On previous versions, you would likely need to utilize a SQL script to determine the

transactions that were in IV but not GL or vice versa.

Released V1.0 Microsoft Dynamics GP 2013 New Features

25

Reconcile to GL window

Figure 15: Reconcile to GL

To access the Reconcile to GL window click Tools on the Microsoft Dynamics GP menu,

point to Routines, point to Financial, and then click Reconcile to GL.

Required fields in this window include Reconciliation, Reconciliation Date, Date Range,

Accounts and Output File information. Once reconciliation has been saved for a given

module, the Accounts and Output File will be saved for future reconciliations. The default

Output File name is made up of the module, Reconciliation value and Month/Year from the

From Date field used in the Date Range.

Note:

The Reconciliation number defaults from the Next Reconciliation field in General Ledger

Setup.

To reconcile your inventory balance to General Ledger, select Inventory from the Module

drop-down.

Note:

Inventory will only be a choice if the Historical Inventory Trial Balance (HITB) has been

activated for that company.

Enter the GL account number(s) of your inventory account and the Date Range you want

analyzed. If you enter a From Date that is prior to the date on which the HITB IV Reset was

performed you will receive the message "HITB was activated on XX\XX\XX. Inventory

reconciliations can't be processed for dates prior to the HITB activation date" and you will

need to adjust your date. If you started using Microsoft Dynamics GP on a version that did

not require a HITB IV Reset and therefore you do not have the DOCTYPE of 100 in your

SEE30303 table, you will never receive this message.

Module 2: Distributions Released V1.0

26

Only the inventory transactions dated with a GL Post Date on or within the date range and

for the selected account(s) will be matched between modules.

Click Process to match transactions found between the modules. Click Save to save your

reconciliation data so you or another user can access it at a later time. This information is

stored in the General Ledger Reconcile Module (GL40401) and General Ledger Reconcile

Module Accounts (GL40402) tables.

Note:

The MODULE1 value in the GL40401 and GL40402 tables for Inventory is 26.

The detail of the transactions used for the reconciliation are stored in permanent tables

which are cleared each time a new reconcile is started. For Inventory, the tables used are

the following:

GL50501 - GLIV_PMatch_TRX_WORK - holds the GL side of the potentially matched

transactions.

GL50502 - GLIV_UMatch_TRX_WORK - holds the GL side of the unmatched transactions.

IV50501 - IV_PMatch_TRX_WORK - holds the Inventory side of the potentially matched

transactions.

IV50502 - IV_UMatch_TRX_WORK - holds the Inventory side of the unmatched

transactions.

These tables may be helpful in troubleshooting if it is easier to get the SQL results rather

than the Excel output.

Note:

Only one user can access a given Reconciliation at any time.

Functionality Described

Select Inventory from the Module drop-down in the Reconcile to GL window. This will

allow you to compare the transactions in the SEE30303 table to the transactions in the

GL20000, and GL30000 tables for the account or accounts you have selected within the date

range entered. When you click Process, a comparison is performed to match transactions

between GL and IV and an Excel spreadsheet is prepared.

The Excel spreadsheet is broken into 3 sections: Unmatched Transactions, Potentially

Matched Transactions and Matched Transctions. The section a given transactions falls into

depends on whether the attributes in the following table match.

Note:

The order the fields are listed in the table indicates the order they are matched in.

Released V1.0 Microsoft Dynamics GP 2013 New Features

27

Inventory (HITB)

General Ledger

Notes

Transaction Source

Originating Transaction Source

Journal Entry Number

Journal Entry Number

Document Number

Originating Control Number

If the GL value is blank, the

transaction was likely posted in

summary. If the GL value is

populated, the GL transaction is

matched with the IV transaction

that has the same document

number.

GL Post Date

Transaction Date

Extended Cost

Debit Amount or Credit Amount

If the Extended Cost is positive,

it will be compared to the Debit

Amount for the account. If it is

negative, it will be compared to

the Credit amount.

The first step in the matching process is to build an initial set of "Matched Transactions"

from GL and Inventory. The Transaction Source and Originating Transaction Source are

compared first, followed by the Journal Entry Number. Records matched in the first step

that do not match on the Journal Entry column are removed from the matched list. Next the

Document Number and Originating Control Number are compared and the transaction

remains matched if they are the same value.

Note:

If the Originating Control Number is blank, the transaction is not excluded. However, if it

is different the transaction will be moved to the "Potentially Unmatched" section.

After the initial set of "Matched Transactions" is built, transactions are further reviewed for

potential matches based on the date and amount fields. If both the date and amounts match,

then the transaction is classified under "Potentially Matched Transactions." However, if

more than one potential match is found for a transaction it will not be listed as a potential

match.

Finally another review is made of the "Matched Transactions" and if the date or amount

fields do not match, then those transactions are moved to the "Potentially Matched

Transactions" section.

Those transactions that were never matched, are displayed under the "Unmatched

Transactions" section.

Module 2: Distributions Released V1.0

28

Excel Output

Figure 16: Output of Excel file

The Excel file that is generated is two distinct sets of data. There is the Inventory

Transactions side on the left that displays the following data from the HITB (SEE30303)

table.

GL Post Date

Transaction Source

Document Number

Journal Entry Number

Extended Cost

On the right side is transaction information from the General Ledger (GL20000 and

GL30000) tables. This includes the following information:

Transaction Date

Journal Entry

Orig. Transaction Source

Orig. Control Number

Account

Debit

Credit

You can use the information in the Unmatched Transactions and Potentially Matched

Transactions sections to determine areas where HITB and GL were not updated with the

same information.

Released V1.0 Microsoft Dynamics GP 2013 New Features

29

Once the Excel spreadsheet is generated, you can drill into the Journal Entry and Document

Number fields. This will allow you to view additional detail for the records displayed.

Explanation of financial fields

Figure 17: Cut of Reconcile to GL

The following is an explanation of the financial fields that are displayed at the bottom of the

Reconcile to GL window.

Subledger - Beginning Balance: Calculated as the sum of the Extended Cost values of the

records in the SEE30303 table with a GL Post Date prior to the From Date entered.

Subledger - Ending Balance: Calculated with the Beginning Balance - IV value plus the sum

of the Extended Cost in the transaction detail returned from the SEE30303 table.

General Ledger - Beginning Balance: Calculated as the balance of the account one day

before the From Date. This balance should be the same as printing the Detailed Trial

Balance for the account with the end date of the report being one day before the From Date

of the reconcile process.

General Ledger - Ending Balance: Calculated using the GL Beginning Balance plus the sum

of debits minus the sum of credits for the detailed journal entries from GL.

Difference: The value difference between the Beginning Balance and Ending Balance for

Inventory and for General Ledger.

Try This: Reconcile Inventory balance to GL

Take what you have learned and do a reconciliation of your inventory account.

1. In the Reconcile to GL window, choose the Module of Inventory.

2. Enter your inventory account in the Accounts area.

3. Provide a file path for the Output File.

4. Click Process and review the Excel output for reasons GL and Inventory are not in

balance.

Module 2: Distributions Released V1.0

30

Lesson Review

Topics covered in this lesson include the following:

The HITB (SEE30303) table is used to determine what transactions do not match

between inventory and general ledger.

Transactions between the modules can be Matched, Potentially Matched, or Unmatched

transactions. These matches can be saved and reviewed at a later time.

Answer the following questions to confirm your understanding of lesson topics.

1. Can you select Inventory as the Module in the Reconcile to GL window if the HITB

report has not been activated?

No. Since the SEE30303 is utilized to the reconciliation, HITB must be activated to reconcile.

2. Once you close the Reconcile to GL window, can you get review to the reconciliation

results again?

Yes. Select the associated Reconciliation number from the lookup to access the results again.

Released V1.0 Microsoft Dynamics GP 2013 New Features

31

Lesson #5: Standard Cost Adjustment

This lesson introduces the Change Item Standard Cost window. The lesson will show how it

can help you keep your Inventory and General Ledger in balance when you use items with a

Periodic valuation method.

What You Will Learn

After completing this lesson, you will be able to:

Describe how to use the Change Item Standard Cost window.

Set up your item to be able to successfully change the standard cost.

Explain how using the utility affects Inventory reports.

Standard Cost Adjustment

If you are using a FIFO Periodic or LIFO Periodic valuation method for your items, you may

have reason to change the Standard Cost. This is typically done at year-end or during other

scheduled times throughout the year. The new Standard Cost Adjustment window allows

you to post to General Ledger when you make a change to the standard cost of your item.

This allows Inventory and GL to stay in balance when the value of your item changes with

the standard cost change. A new Standard Cost Revaluation account will be used to handle

the transaction.

Note:

On previous versions of Microsoft Dynamics GP: if you changed the standard cost of

your item, no journal entry was made in the General Ledger. This would cause an out of

balance situation between GL and IV. In addition, the Historical Inventory Trial Balance

(HITB) did not track the changing of the standard cost.

Changes to Windows

Changes were made to a few inventory windows and the Standard Cost Adjustment window

was added. This section reviews those changes.

Item Maintenance window

The Standard Cost field in Item Maintenance will now be read only for your items with a

periodic valuation method. To open Item Maintenance on the Cards menu, point to

Inventory, and then click Item.

Module 2: Distributions Released V1.0

32

Figure 18: Item Maintenance

If you attempt to change the standard cost of a periodic item, you will receive the message

"You cannot change the standard cost of this item in this window. Use the Change Item

Standard Cost window to change the standard cost of this item."

Note:

A different warning message will appear if Manufacturing is used.

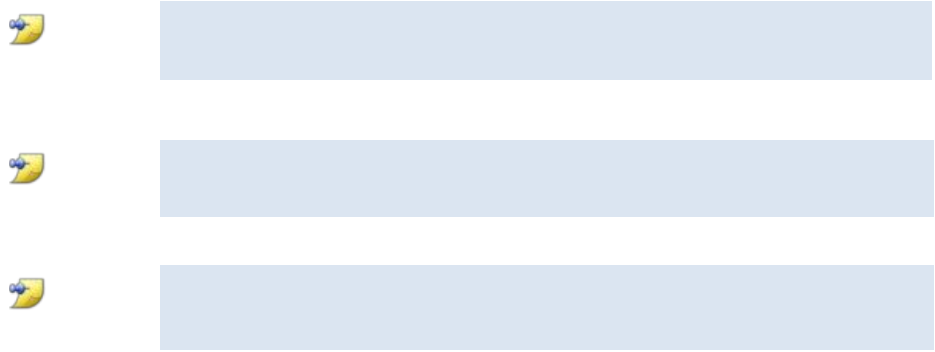

Item Account Maintenance window

A new account of Standard Cost Revaluation has been added to Item Account Maintenance.

To open the Item Account Maintenance window from the Cards menu point to Inventory,

and then click Item. After selecting your item, click Accounts.

Released V1.0 Microsoft Dynamics GP 2013 New Features

33

Figure 19: Item Account Maintenance

The Standard Cost Revaluation account will be used in conjunction with the Inventory

account to make the General Ledger entry for the standard cost change. The account index

is stored in the IV00101 table in the IVSCRVIX field.

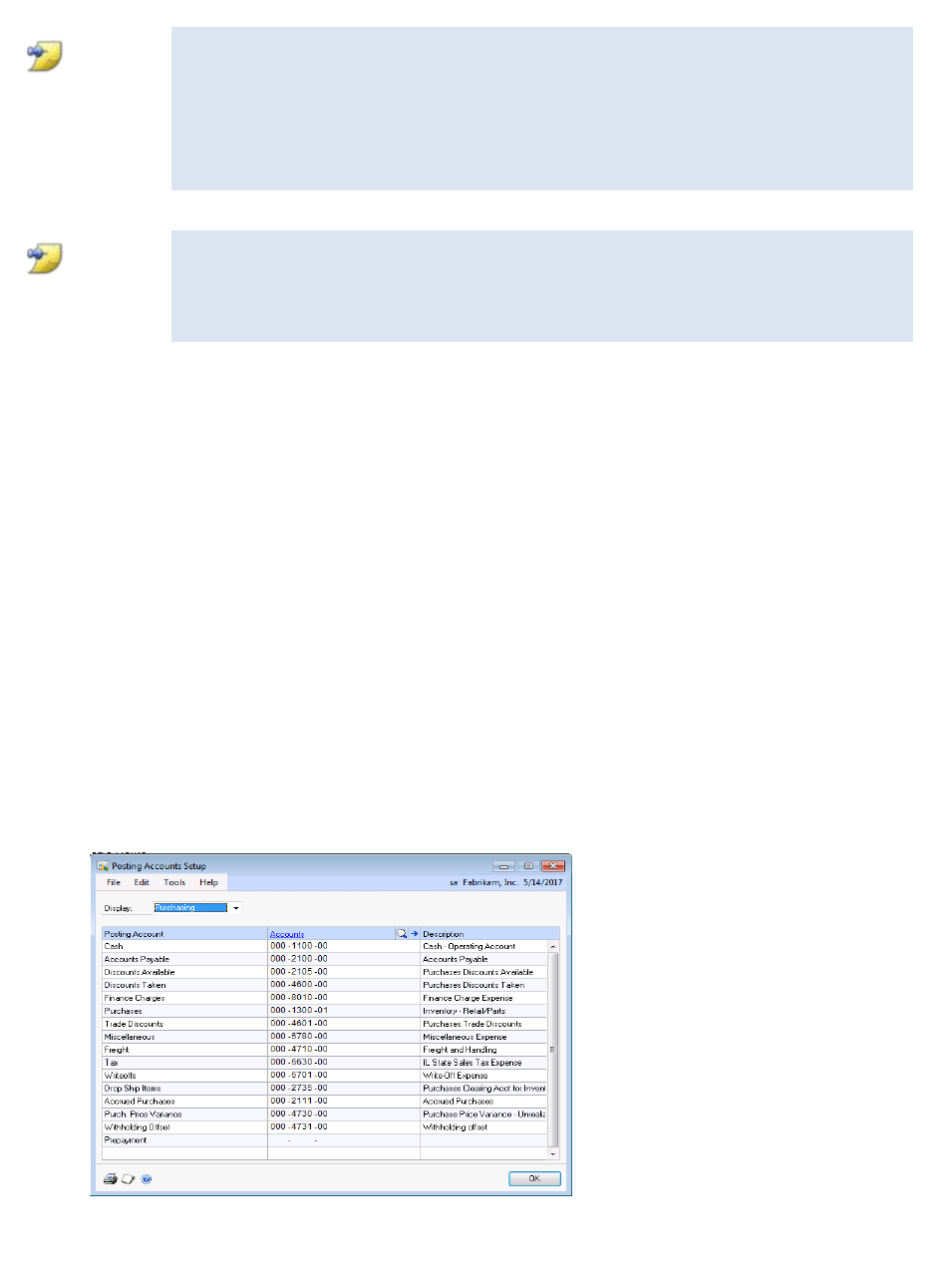

Note:

The Standard Cost Revaluation account has also been added to Posting Accounts Setup

under the Display of Inventory, and to the Item Class Account Maintenance window.

If the Standard Cost Revaluation account is not entered in Item Account Maintenance,

then the account in Posting Account Setup will be used. If no account is in either place,

then the cost change will not occur.

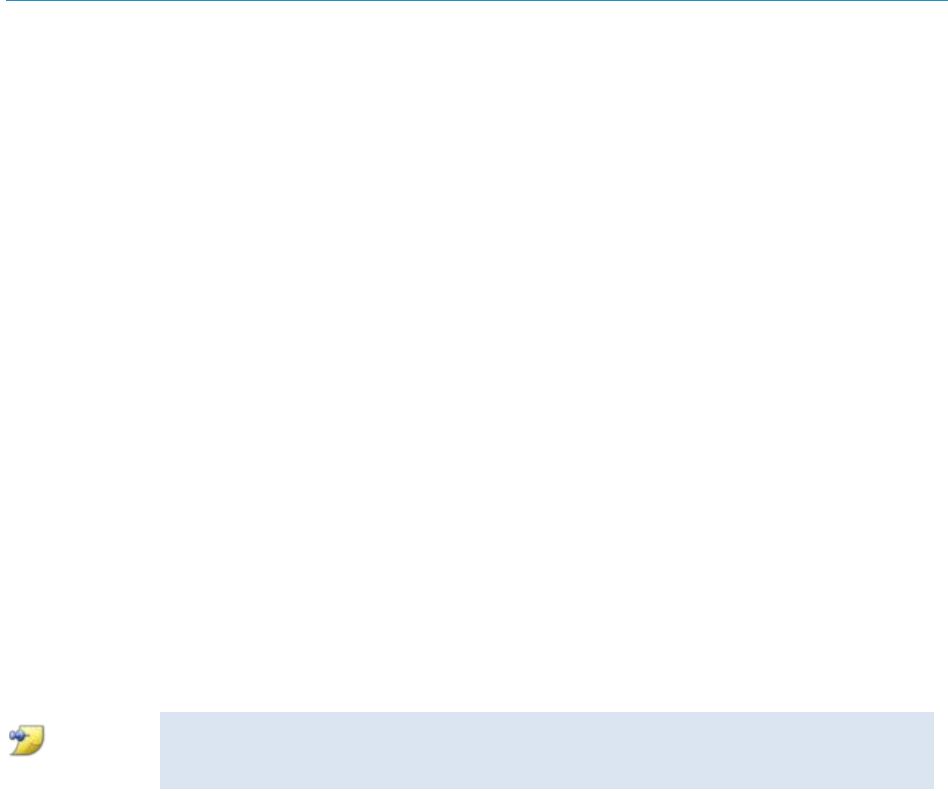

New: Change Item Standard Cost window

Use the Change Item Standard Cost window to make a change to the standard cost of your

items with a periodic valuation method. To open the Change Item Standard Cost, on the

Microsoft Dynamics GP menu, point to Tools, point to Utilities, point to Inventory, and

then click Change Item Standard Cost.

Figure 20: Change Item Standard Cost

Module 2: Distributions Released V1.0

34

Note:

If you are registered for Manufacturing, you will not be able allowed to open this

window. Instead, change the standard cost of your item using Standard Item Material

Costs, Standard Cost Changes, or the Roll Up and Revalue Inventory window.

Enter the item whose standard cost you want to change. You can only change the cost of

one item at a time and you can only enter items that have a valuation method of LIFO

Periodic or FIFO Periodic. Enter the new standard cost in the New Standard Cost field. Click

Process to commit your changes.

When you click Process, several things occur if the change is successful:

The Standard Cost field in Item Maintenance is updated with the new cost.

An adjustment is made to General Ledger using the Inventory and Standard Cost

Revaluation accounts. This will post to GL (never through) in a GLTRX batch to be

posted. The Reference is Standard Cost Revaluation.

A record is added to the Historical Inventory Trial Balance (SEE30303) table as a

variance transaction so that record of the change is shown on the report. The date

used to record the change is the GP User Date.

The Standard Cost Posting Journal report will print.

If the cost change could not be made, none of the above will occur and instead the Item

Standard Cost Change Exception report is printed.

Note:

To have access to this window use security task ID ADMIN_INV_006*.

The General Ledger adjustment that is created is calculated by taking the Quantity on Hand

of the item by the difference in the item's old and new standard cost. For example, you have

10 on hand and a current standard cost of $10. You then change the standard cost to be $12.

The entry to GL will be a debit to Inventory and a credit to Standard Cost Revaluation of $20

(10 x $2).

Note:

If Segment ID for sites has been implemented, the account site substitution will be

made.

Note:

If the item you change the cost for has a Quantity on Hand of 0, the cost change will still

be made even if you do not have the proper posting accounts set up. You will receive

the message "There is no change to the inventory value. A standard cost revaluation

batch will not be created. Standard unit cost changes for item without quantity on hand

will take effect."

Released V1.0 Microsoft Dynamics GP 2013 New Features

35

Adjust Cost Utility

You will no longer be able to use the Adjust Cost Utility window to change the cost of a

receipt for a periodic valuation item. Instead, you will receive the message "You cannot

change the unit cost for periodic items."

To access Inventory Adjust Costs on the Microsoft Dynamics GP menu, point to Tools,

point to Utilities, point to Inventory, and then click Adjust Cost.

Inventory Year-End Closing

Figure 21: Inventory Year-End Closing

To open the Inventory Year-End Closing window on the Microsoft Dynamics GP menu,

point to Tools, point to Routines, point to Inventory, and then click Year-end Close. When

you close your inventory year by using this window and you select the Item's Standard

Cost option under the Update area, several things occur when you click Process.

The Standard Cost field in Item Maintenance is updated with the Current Cost on the

item.

An adjustment is made to General Ledger using the Inventory and Standard Cost

Revaluation accounts. This will post to GL (never through) in a GLTRX batch to be

posted. The Reference is Standard Cost Revaluation. This transaction will be made in

summary of all the items affected.

A record is added to the Historical Inventory Trial Balance (SEE30303) table as a

variance transaction so that record of the change is shown on the report. The date

used to record the change is the GP User Date.

The Standard Cost Posting Journal report will print.

Note:

If the Current Cost and Standard Cost are already the same for the item, no adjustment

is made.

Module 2: Distributions Released V1.0

36

Changes to Reports

Two new reports were added to account for the tracking of the change in standard cost. The

change also affects some existing reports.

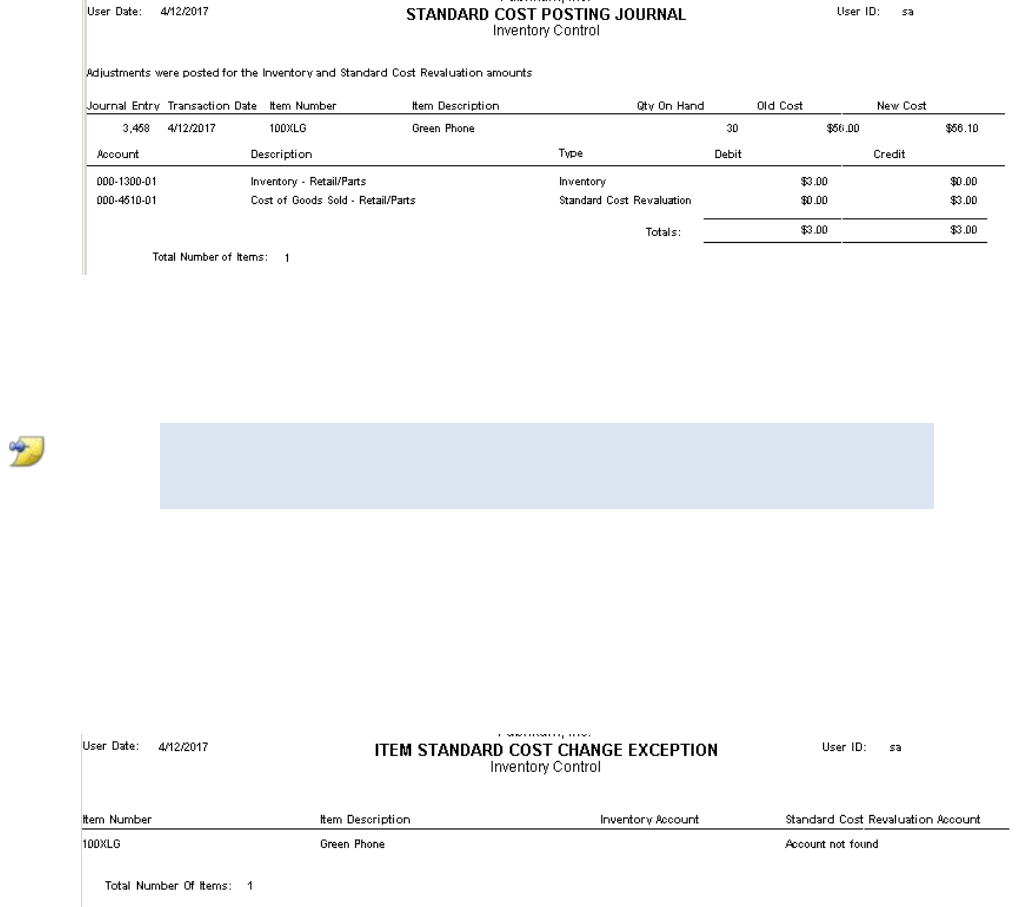

New: Standard Cost Posting Journal report

The Standard Cost Posting Journal report will be printed after you click Process and close

the Change Item Standard Cost window. The report records the successful change of your

standard cost by showing both your old and new cost.

Figure 22: Output of Standard Cost Posting Journal

It is not possible to reprint this report as it is pulled from a new temporary table called

IV_STD_Cost_ADJ_TEMP.

Note:

The same report is generated from the Inventory Year-end Closing window, if you

choose to update the item's standard cost and it is successful.

New: Item Standard Cost Change Exception report

If the Inventory or Standard Cost Revaluation accounts are not found, the Item Standard Cost

Change Exception report is printed and the item's standard cost is not changed. This report

is generated after you click Process and close the Change Item Standard Cost window.

Figure 23: Output of Item Standard Cost Change Exception report

Released V1.0 Microsoft Dynamics GP 2013 New Features

37

Once you enter the missing account, use the Change Item Standard Cost window to make

your cost change again.

This report is printed using the new IV_STD_Cost_ADJ_ExceptionTemp table.

Note:

The same report is generated from the Inventory Year-end Closing window, if you

choose to update the item's standard cost. However, one or more accounts could not be

found.

Historical Inventory Trial Balance (HITB)

When the standard cost of a FIFO or LIFO Periodic item is changed, a record will be printed

on the Historical Inventory Trial Balance (HITB) report, recording this change. Since the

change only resulted in a value change for the item and not a quantity change, the report

will show the change as a variance transaction.

The transaction will be recorded with a DOCTYPE of 8. (This is already being used for the

Adjust Cost Utility.)

Item Report changes

The Inventory Class report and Posting Accounts report have been updated to reflect the

new posting account type of Standard Cost Revaluation.

Try This: Change the standard cost of your item

Take what you have learned in this lesson and use the new Change Item Standard Cost

utility to change the standard cost of your item.

1. In Item Maintenance, select an item that is set up with a FIFO Periodic or LIFO Periodic

valuation method. Note the current Standard Cost value and that you cannot change it.

Verify Quantity on Hand is greater than 0.

2. Verify a Standard Cost Revaluation account has been assigned to the item.

3. Use Change Item Standard Cost to select the item and enter a different cost.

4. Click Process, and review the report.

5. Select the item in Item Maintenance again, and review the new Standard Cost.

Module 2: Distributions Released V1.0

38

Lesson Review

Topics covered in this lesson include the following:

A new account type of Standard Cost Revaluation has been introduced to track changes

in the standard cost when the item has quantity on hand.

Using the Change Item Standard Cost window will change the item's Standard Cost and

send a transaction to General Ledger to account for the variance. It will also update the

HITB report to keep GL and Inventory in balance.

Answer the following questions to confirm your understanding of lesson topics.

1. Can you change the Standard Cost of an item with a Periodic Valuation Method in Item

Maintenance?

No. Use the new Change Item Standard Cost window to make changes to your standard cost by

item.

2. Will General Ledger be affected when you make a change to your standard cost?

Yes, as long as there is existing quantity for the item.

Released V1.0 Microsoft Dynamics GP 2013 New Features

39

Lesson #6: Inactivate Sites

This lesson explains the functionality of being able to inactivate inventory sites, as well as

inactivate a specific item/site combination.

What You Will Learn

After completing this lesson, you will be able to:

Describe how to inactivate a site.

Explain what transactions are prevented when a site is inactive.

Inactivate Sites and Item/Site combinations

You can now mark an inventory site as inactive. This prevents additional quantity

movement in this site.

If the site as a whole does not need to be inactivated, but a specific item can no longer be

sold from or purchased for a site, then that item's site can be inactivated.

Note:

On previous versions, it was not possible to inactivate a site. If it was no longer needed it

would have to be deleted. However, that was not always possible due to historical

transactions.

Changes to Windows and Reports

Windows have been updated so that inactivation can occur. The Site List report shows this.

This section will detail those changes.

Site Maintenance window

An Inactive checkbox has been added to the Site Maintenance window. To open Site

Maintenance from the Cards menu, point to Inventory, and then click Site.

Figure 24: Site Maintenance

Module 2: Distributions Released V1.0

40

The Inactive checkbox can be marked at any time, including when unposted transactions for

it exist for the site.

Item Quantities Maintenance window

An Inactive checkbox has been added to the Item Quantities Maintenance window. To open

Item Quantities Maintenance from the Cards menu, point to Inventory, and then click

Quantities/Sites.

Figure 25: Item Quantities Maintenance

If you select a site that is marked as inactive, you will receive a message "This site is already

marked as inactive." You can click OK and review the information for this item/site

combination.

The Inactive checkbox can be marked at any time, including when unposted transactions for

it exist for the item/site combination.

Site List

The Site List report will now include information on whether or not the site is marked as

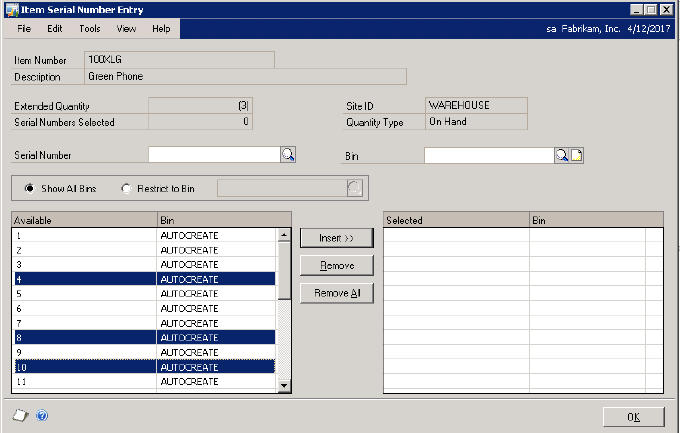

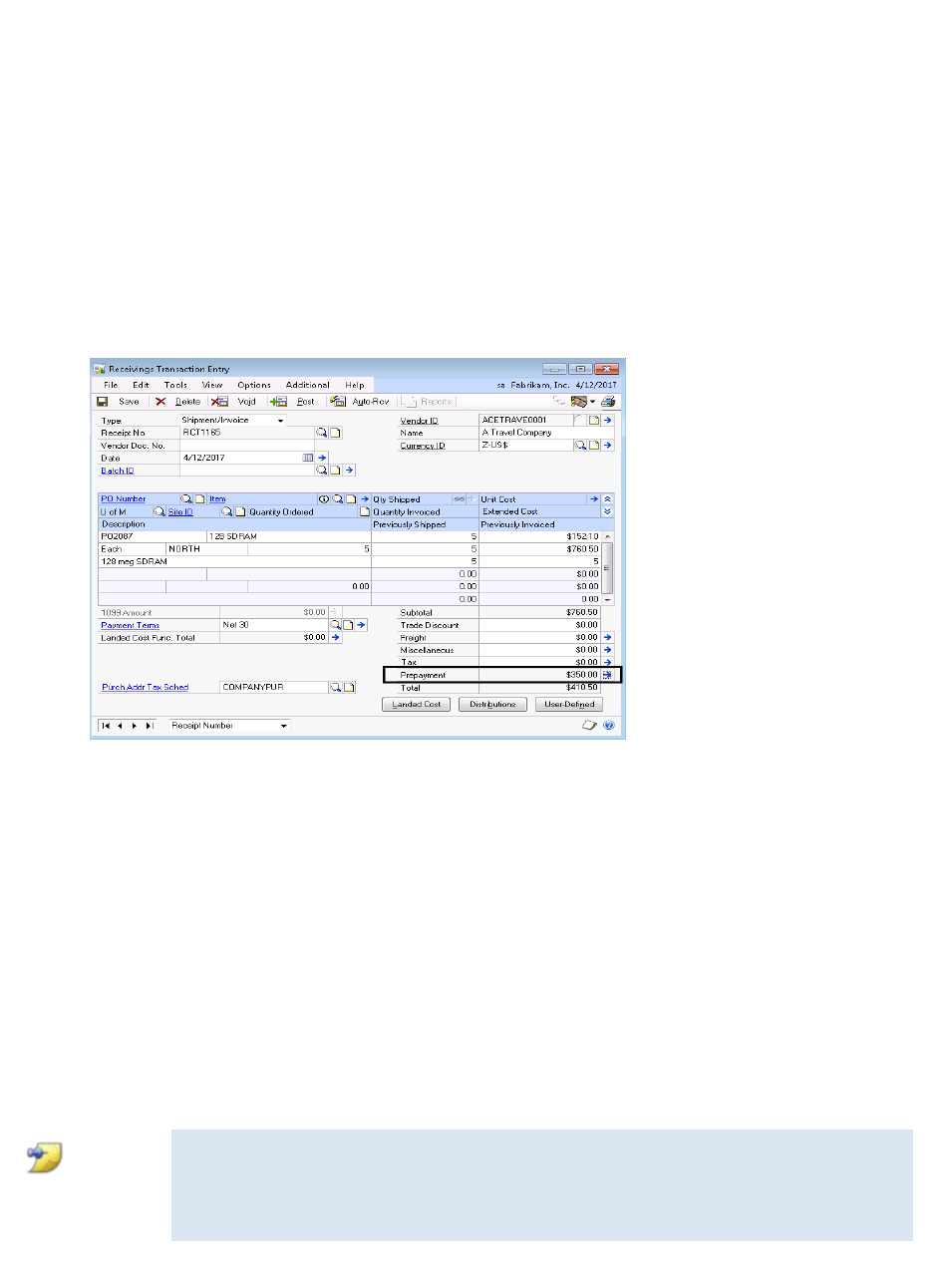

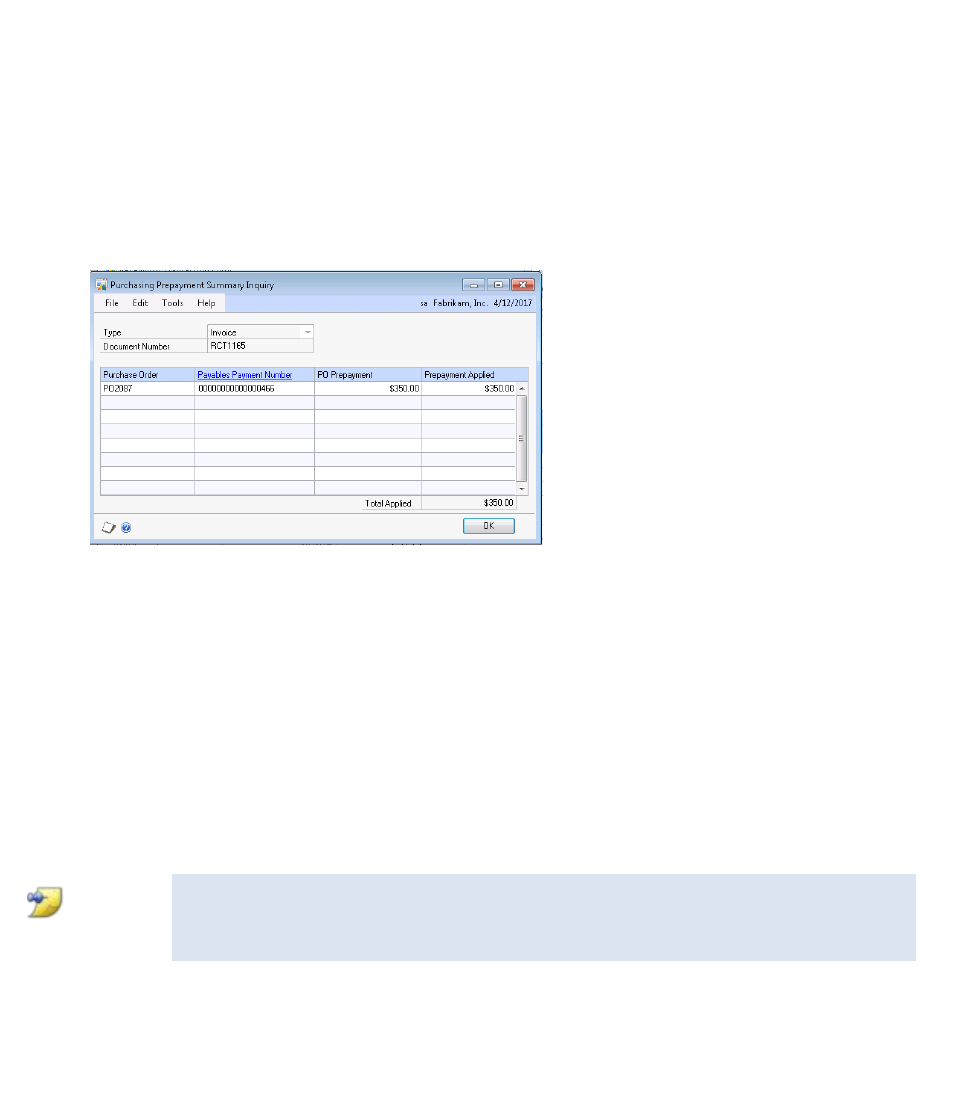

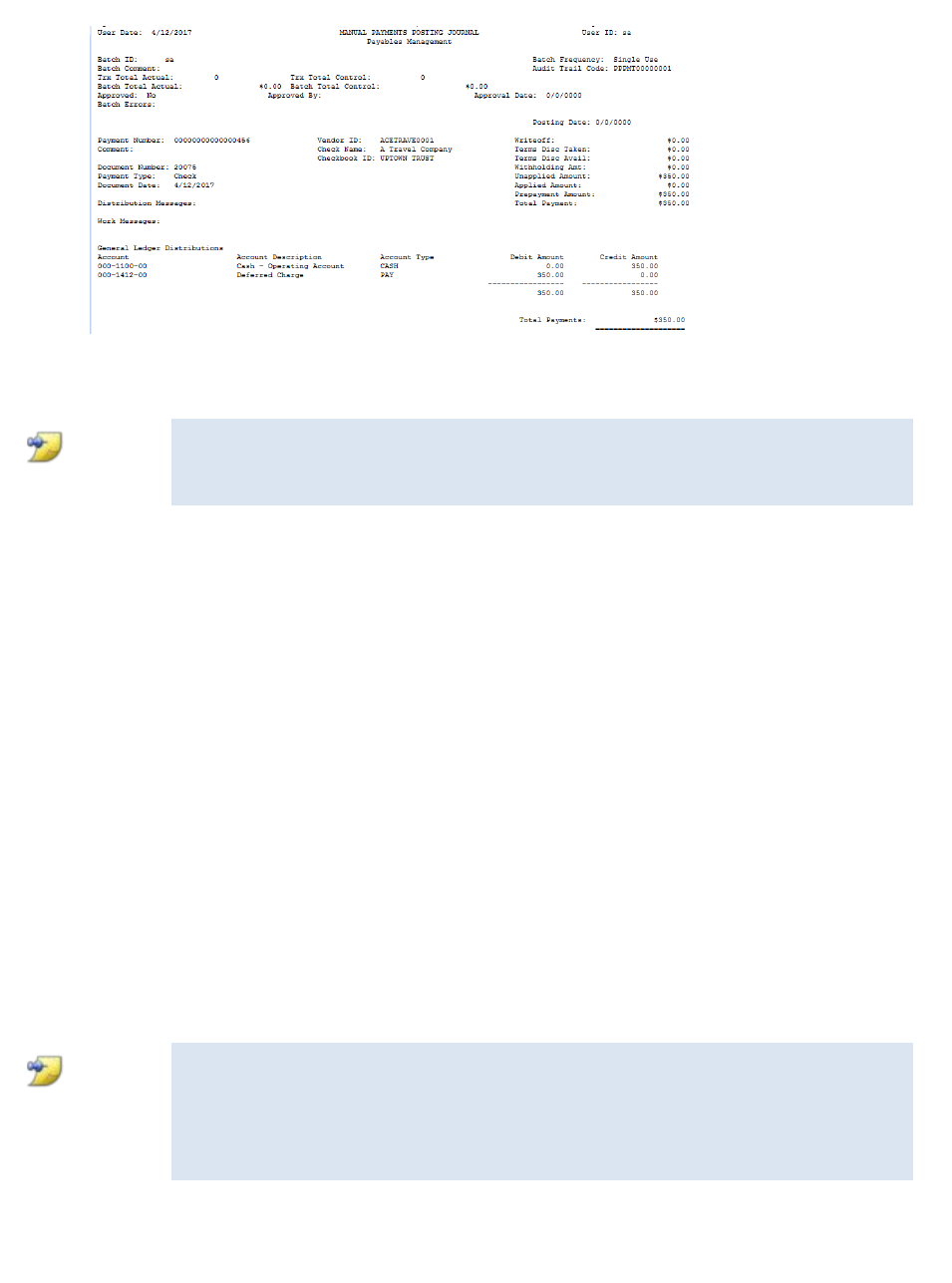

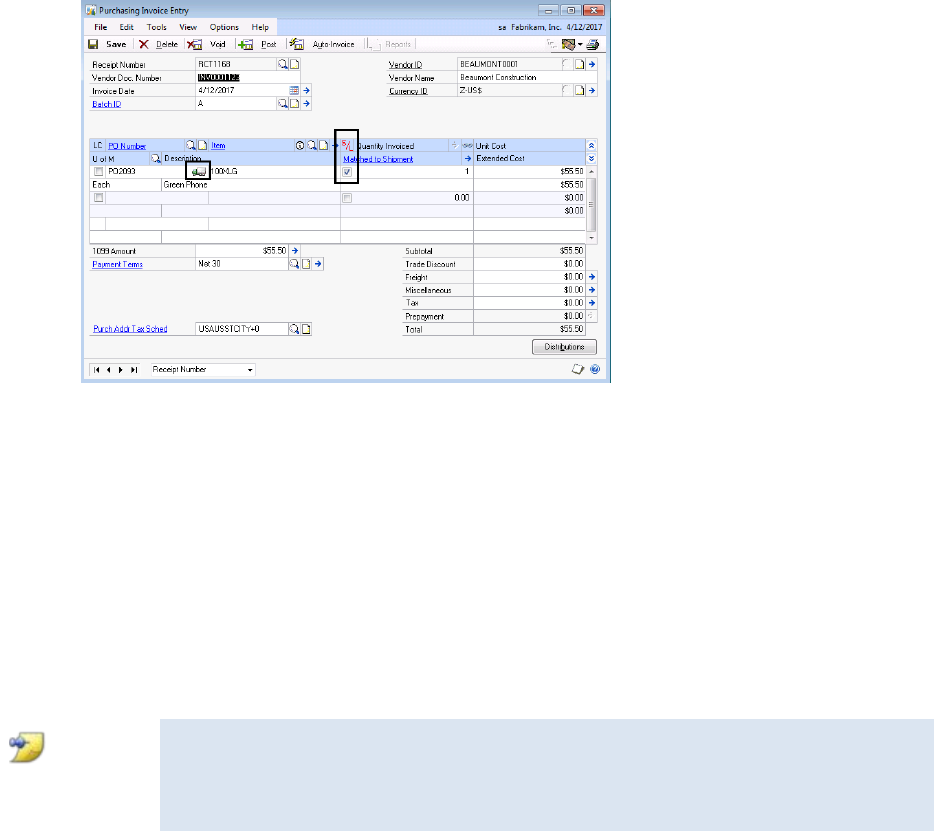

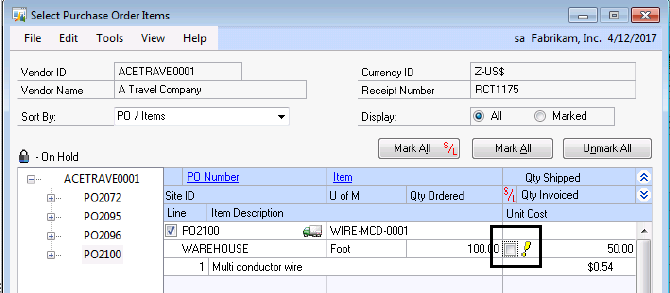

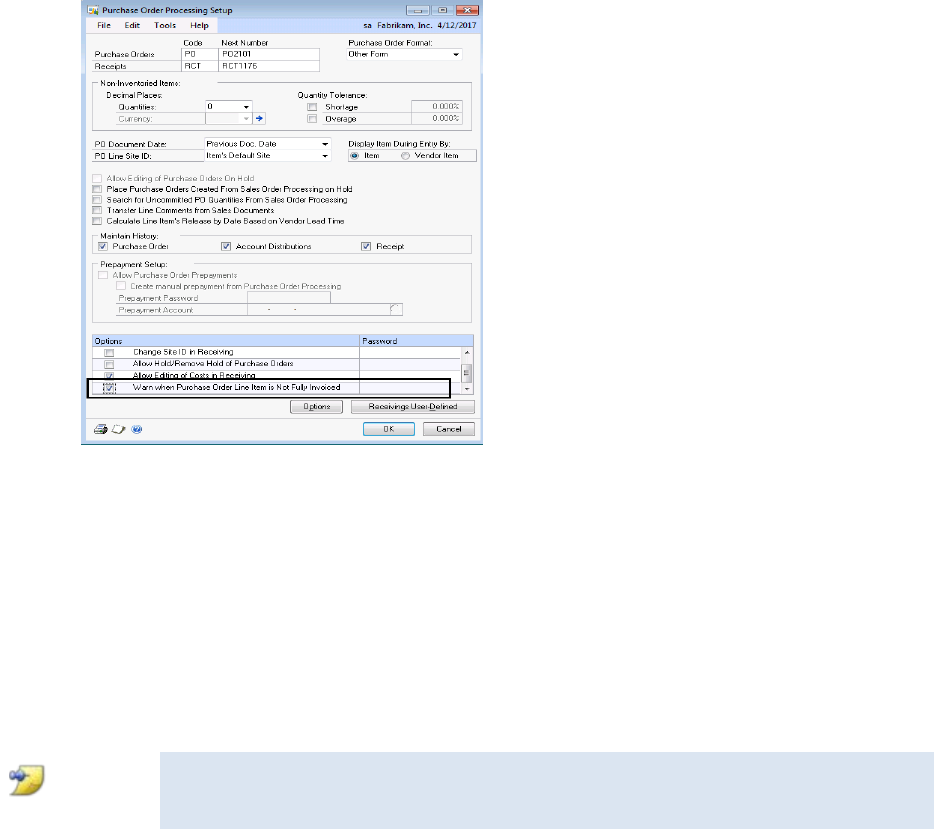

inactive. You can choose whether you would like to exclude inactive sites from the report as