1

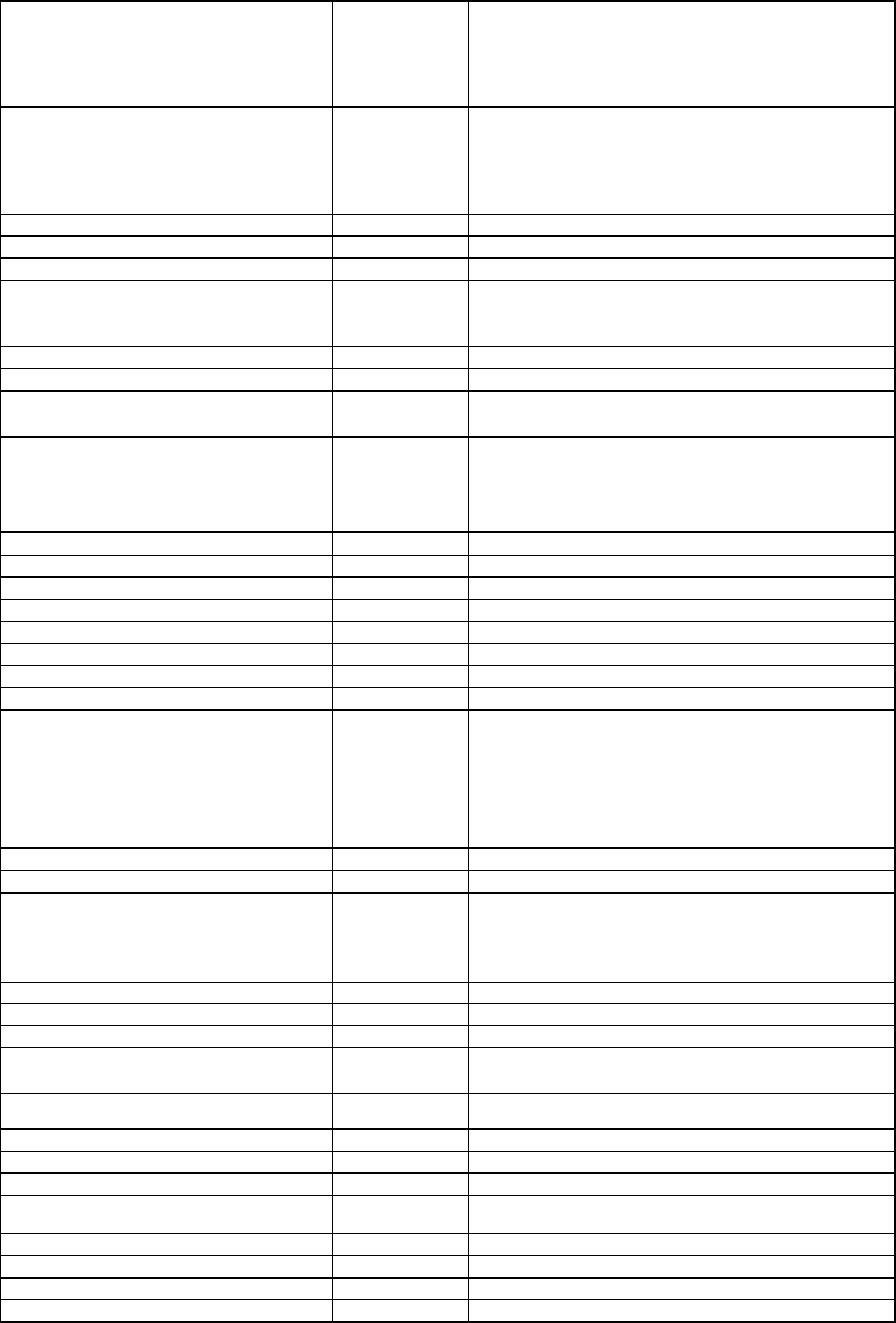

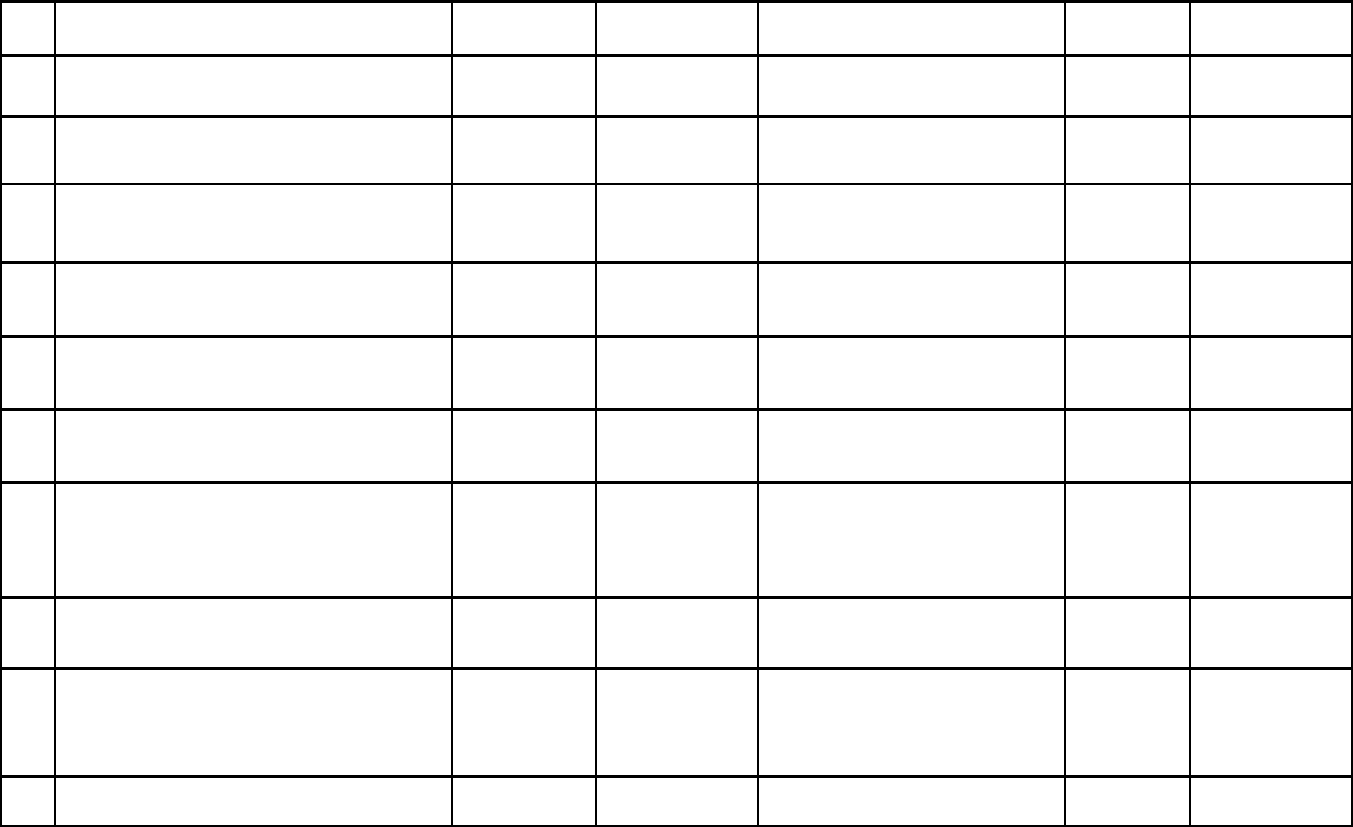

Codification through the 2023 Legislative session

Subchapter 23

Board adoption February 17, 2023

Approved by SJR 22 on May 31, 2023 Effective date

September 15, 2023

TITLE 252. DEPARTMENT OF ENVIRONMENTAL QUALITY

CHAPTER 515. MANAGEMENT OF SOLID WASTE

Subchapter Section

1. General Provisions 252:515-1-1

3. Permit Provisions and Applications 252:515-3-1

5. Location Restrictions 252:515-5-1

7. Subsurface Investigation 252:515-7-1

9. Groundwater Monitoring/Corrective Action 252:515-9-1

11. Liner Design 252:515-11-1

13. Leachate Collection and Management 252:515-13-1

15. Methane Gas Monitoring and Control 252:515-15-1

17. Stormwater Management 252:515-17-1

19. Operational Requirements 252:515-19-1

21. Used Tire Processing, Certification, Permits and Compensation 252:515-21-1

23. Regulated Medical Waste Management 252:515-23-1

25. Closure and Post-closure Care 252:515-25-1

27. Cost Estimates and Financial Assurance 252:515-27-1

29. Exclusion of Prohibited Wastes 252:515-29-1

31. NHIW Management 252:515-31-1

33. Waste Collection and Transportation 252:515-33-1

35. Oklahoma Recycling Initiative 252:515-35-1

37. Landfill Gas Incentive Payments 252:515-37-1

39. Oklahoma E-Waste Recycling 252:515-39-1

41. Roofing Material Recycling 252:515-41-1

43. Composting Facilities 252:515-43-1

Appendix A. Constituents for Detection Monitoring

Appendix B. Uppermost Aquifer Protective Values

Appendix C. List of Hazardous Inorganic and Organic Constituents

Appendix D. Borings in Drilling Plan

Appendix E. Borehole Depth Calculation Table

Appendix F. NHIW Wastestreams

Appendix G. NHIW Certification Form

Appendix H. Procedure for Calculating Closure Cost Estimates for Financial Assurance

Appendix I. Procedure for Calculating Post-closure Cost Estimates for Financial Assurance

1

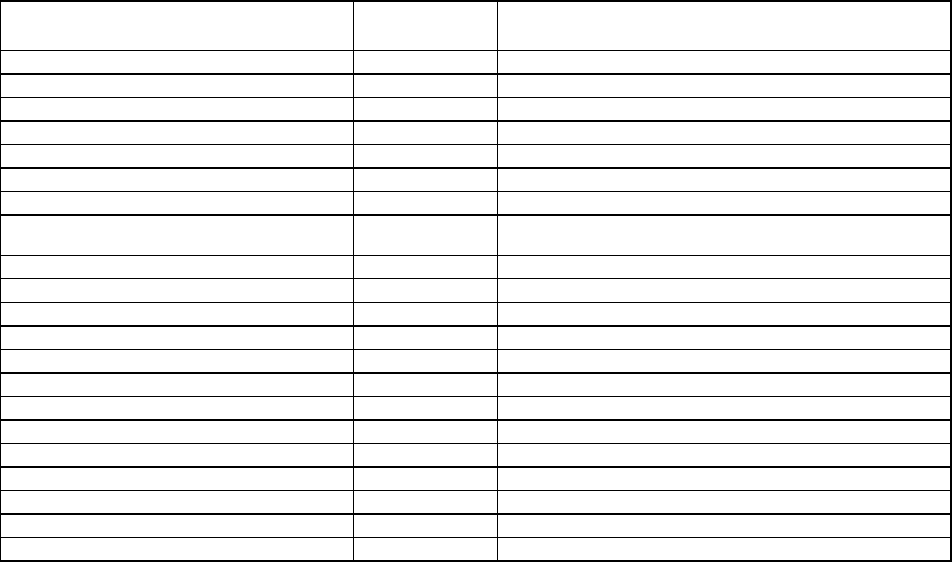

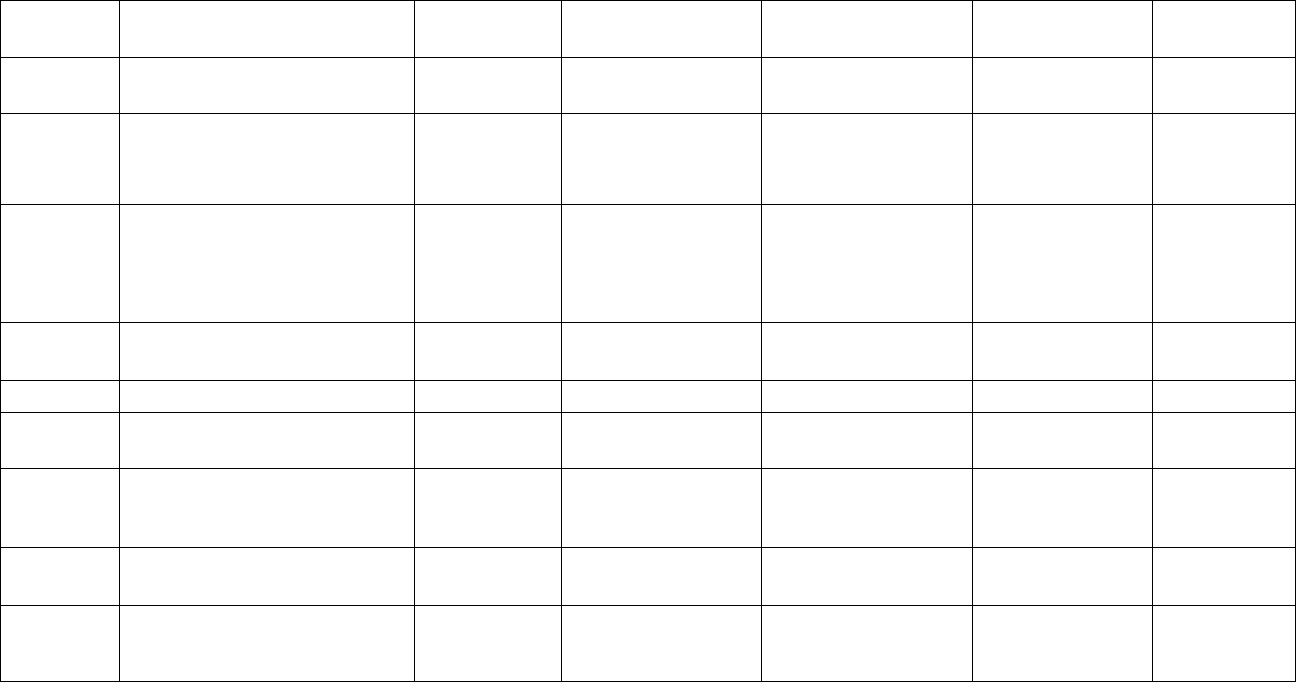

SUBCHAPTER 1. GENERAL PROVISIONS

Section

252:515-1-1. Authority and applicability

252:515-1-2. Definitions

252:515-1-3. Terms not defined by Act or rule

252:515-1-4. Test methods and map scales

252:515-1-5. Consideration of other laws

252:515-1-6. Severability

252:515-1-7. Beneficial reuse

252:515-1-8. Special considerations

252:515-1-1. Authority and applicability

(a)

Authority. This Chapter implements the Oklahoma Solid Waste Management Act, 27A O.S.

§ 2-10-101 et seq., and the Oklahoma Waste Tire Recycling Act, 27A O.S. § 2-11-401 et seq., and

was adopted under their authority and the authority of the Oklahoma Environmental Quality Code,

27A O.S. § 2-1-101 et seq.

(b)

Applicability. This Chapter applies to:

any person who owns, operates, or proposes to own and/or operate any type of solid waste disposal

facility identified in OAC 252:515-3-1(a) and (b);

(1)

any person who generates, collects, transports, processes, and/or disposes of solid waste

and/or waste tires, unless otherwise exempt;

(2)

incorporated cities and towns in Oklahoma providing solid waste collection and

transportation services within the corporate city or town limits;

(3)

governmental entities located in the state of Oklahoma desiring to seek reimbursement

under the Oklahoma Recycling Initiative; and

(4)

any person, firm or corporation located in Oklahoma desiring to apply for incentive

payments for projects that generate energy by utilizing solid waste landfill methane gas.

252:515-1-2. Definitions

The following words or terms, when used in this Chapter, shall have the following meaning,

unless the context clearly indicates otherwise. Any term not defined in this Chapter shall be defined

as set forth in OAC 252:515-1-3.

"Active" means, when used to describe a solid waste disposal facility or a portion thereof (e.g.,

active MSWLF or active cell), any solid waste disposal facility, or portion thereof, accepting solid

waste as of the effective date of this Chapter, regardless of whether such facility has obtained a solid

waste permit from DEQ.

"Active life" means the period of operation beginning with the initial receipt of solid waste and

ending at completion of closure activities.

"Active portion" means:

(A)

that part of a land disposal facility that has or is receiving waste and that has not

received either intermediate or final cover; or

(B)

solid waste process and storage areas at non-land disposal facilities.

"Airport" means a public-use airport open to the public without prior permission, and without

restrictions within the physical capacities of available facilities.

"Applicant" means any person who applies for a new permit or a modification to an existing

2

permit for a solid waste disposal facility identified in OAC 252:515-3-1(a) and (b).

"Aquifer" means geological formation, group of formations, or portion of a formation

capable of yielding significant quantities of groundwater to wells or springs.

"Areas susceptible to mass movement" means those areas of influence (i.e., areas

characterized as having an active or substantial possibility of mass movement) where the

movement of earth material at, beneath, or adjacent to the land disposal facility, because of natural

or man-induced events, results in the downslope transport of soil and rock material by means of

gravitational influence. Such areas include, but are not limited to, landslides, avalanches, debris

slides and flows, soil fluction, block sliding, and rock fall.

"ASTM" means the American Society for Testing and Materials.

"Bird hazard" means an increase in the likelihood of bird/aircraft collisions that may cause

damage to the aircraft or injury to its occupants.

"Buffer zone" means a designated waste-free area within the permit boundary of a disposal

facility, to separate waste handling, processing, and/or disposal activities from adjacent areas.

"Citizen collection station" means a designated location that is established or sponsored by a

governmental entity and equipped with waste receptacles for exclusive, non-commercial use by

individual residents to deposit their own household waste for collection and transportation to a

permitted disposal site.

"CLIMOCS" means the following publication of the Oklahoma Climatological Survey:

Shafer, Mark A., CLIMOCS: A Climatological Summary of 168 Oklahoma Cooperative Stations,

Oklahoma Climatological Survey, February 1993, 184 pp.

"Composite liner" means a system installed at a land disposal facility composed of a

recompacted clay liner overlain with a flexible membrane liner.

"C&D landfill" means a construction/demolition landfill.

"Composting facility" means a facility in which material is converted, under thermophilic

conditions, to a product with a high humus content for use as a soil amendment or to prevent or

remediate pollutants in soil, air, and stormwater run-off.

"Construction/demolition waste" means waste composed of the following:

(A)

asbestos-free waste from construction and/or demolition projects that may include such

materials as metal, concrete, brick, asphalt, glass, roofing materials, limited amounts of

packing materials, sheetrock, or lumber;

(B)

wood waste that may include such materials as yard waste, lumber, woodchips, wood

shavings, sawdust, plywood, tree limbs, or tree stumps;

(C)

yard waste that may include such materials as grass clippings, tree limbs, tree stumps,

shrubbery, flowers, or other vegetative matter resulting from land clearing or landscaping

operations; or

(D)

residential lead-based paint waste.

"Contaminated stormwater" means:

(A)

water such as leachate and gas collection condensate, or stormwater that has come into

direct contact with solid waste or waste handling and/or treatment areas;

(B)

stormwater discharged from areas of a land disposal facility with less than six inches of

waste-free, compacted earthen material; or

(C)

wastewater resulting from washing vehicles or areas that are or have been in direct

contact with solid waste.

"DEQ" means the Oklahoma Department of Environmental Quality.

"Disease vector" means rodents, flies, mosquitoes, or other animals, including insects, capable

3

of transmitting disease to humans.

"Displacement" means the relative movement of any two sides of a fault measured in any

direction.

"Disposal" means the final disposition of waste and shall be taken to include any discharge,

deposit, injection, dumping, spilling, leaking, or placing of waste into or on the land or water so that

the waste or any constituent thereof may enter the environment, including the air and any surface

waters or ground waters.

"Disposal area" means that part of a land disposal facility where waste is disposed.

"Disposal facility" means disposal site as defined at 27A O.S. § 2-10-103.

"Engineer" means a licensed, professional engineer.

"EPA" means the United States Environmental Protection Agency.

"Existing" means, when used to describe a solid waste disposal facility or portion thereof (e.g.

existing MSWLF or existing cell), any solid waste disposal facility, or portion thereof, that had a

solid waste permit as of the effective date of this Chapter.

"Facility" means all contiguous land and structures, other appurtenances, and improvements

on the land used for the handling, processing, storage, and/or disposal of solid waste.

"Fault" means a fracture or a zone of fractures in any material along which strata on one side

have been displaced with respect to that on the other side.

"Final closure" means a disposal facility has permanently ceased to accept solid waste for

disposal and all required closure activities have been completed for the entire facility in accordance

with the approved closure plan. Final closure is not synonymous with phased closure.

"Flood" means the general and temporary condition of partial or complete inundation of

normally dry land areas from the overflow of a lake, stream, river or other body of surface water, or

the unusual and rapid accumulation or runoff of surface waters from any source.

"Flood, One hundred year (100 year)" means a flood that has a one percent or greater chance

of occurrence in any given one year period, or of a magnitude equaled or exceeded once in 100 years

on the average over a significantly long period.

"Flood plain" means the lowland and relatively flat areas adjoining inland waters that are

inundated by the 100-year flood.

"Gas condensate" means the liquid generated as a result of gas recovery processes.

"Generator" means, in the context of NHIW, any person, by site, whose act or process

produces NHIW, or whose act first causes an NHIW to become subject to regulation.

"Groundwater" means water below the land surface in a zone of saturation.

"Hazardous waste" means those wastes subject to regulation under OAC 252:205.

"HBV" means hepatitis B virus.

"HIV" means human immunodeficiency virus.

"Holocene" means the most recent epoch of the Quaternary period, extending from the end of

the Pleistocene Epoch to the present.

"Household hazardous waste" means household waste that is corrosive, toxic, ignitable, or

reactive, including, but not limited to: freon-containing appliances or tanks; non-empty propane

tanks; oil, antifreeze, and other motor vehicle fluids; gasoline, kerosene, or diesel fuel; liquid paints;

solvents; pesticides, herbicides, fungicides, or rodenticides; caustic cleaners; lead-acid batteries;

swimming pool chemicals; unused firearm rounds; and acids and bases.

"Household waste" means any solid waste (including garbage, trash, and sanitary waste in

septic tanks) derived from households (including single and multiple residences, hotels and motels,

bunkhouses, ranger stations, crew quarters, campgrounds, picnic grounds, and day-use recreation

4

areas).

"Injection well" means a facility subject to regulation by OAC 252:652, Underground

Injection Control.

"Karst terrains" means areas where karst topography, with its characteristic surface and

subterranean features, is developed as the result of dissolution of limestone, dolomite, or other

soluble rock. Characteristic features of karst terrains include, but are not limited to, sinkholes,

sinking streams, caves, large springs, and blind valleys.

"Land disposal facility" means a landfill, or any other discrete area of land or land excavation,

where solid waste is placed for treatment, processing, and/or disposal. Land disposal facility does

not include:

(A)

land application where solid waste is placed onto, or incorporated into, the soil

as a soil amendment, fertilizer, or other legitimate agricultural purpose;

(B)

a surface impoundment that is either permitted by DEQ's Water Quality

Division or is a part of an approved liquid waste management system at a permitted solid

waste disposal facility;

(C)

composting facilities;

(D)

an injection well;

(E)

a solid waste transfer station;

(F)

a Used Tire Recycling Facility; or

(G)

a Roofing Material Recycling Facility

"Landfill" means a discrete area of land or a land excavation in which solid waste is placed for

permanent disposal.

"Large NHIW generator" means any business, by site, that generates over 10,000 tons of

NHIW in Oklahoma during a calendar year. This definition does not include facilities that are

permitted to receive and process solid waste generated by others.

"Leachate" means liquid that has passed through or emerged from solid waste and contains

soluble, suspended, or miscible materials removed from such waste. This includes:

(A)

fluid collected in a leachate collection system, including its sumps, surface

impoundments, tanks, or other similar locations;

(B)

fluid collected on top of the bottom liner of a disposal cell that has received solid

waste; and

(C)

leachate seeps from disposal cells that have received solid waste.

"Liquid waste" means any waste that is determined to contain "free liquids" as defined by the

PFLT.

"Lithified earth material" means all rock, including all naturally occurring and naturally

formed aggregates or masses of minerals or small particles of older rock that formed by

crystallization of magma or by induration of loose sediments. This term does not include man-made

materials, such as fill, concrete, and asphalt, or unconsolidated earth materials, soil, or regolith lying

at or near the earth surface.

"Litter fence" means an easily portable fence to be located adjacent to the working face to assist

with control of blowing material.

"Lower explosive limit" means the lowest percent by volume of a mixture of explosive gases

that will propagate flame in air at 2

0

5°C and atmospheric pressure.

"Maximum horizontal acceleration" means the maximum expected horizontal acceleration

of lithified earth material, depicted on a seismic hazard map, with a 90 percent or greater probability

that the acceleration will not be exceeded in 250 years, or the maximum expected horizontal

acceleration based on a site-specific seismic risk assessment.

5

"MSWLF" means Municipal Solid Waste Landfill; a publicly or privately owned landfill that

is or has received household waste. A MSWLF may also receive other types of non-hazardous solid

wastes, such as nonhazardous sludge, NHIW, special waste, and construction/demolition waste.

"Natural disaster" means a natural occurrence or event (such as a tornado, flood, or forest or

prairie fire) of such magnitude that the resultant damage and destruction produce quantities of

wastes that overtax available solid waste management systems.

"NHIW" means non-hazardous industrial solid waste, as defined at 27A O.S. § 2-10-103.

Examples of NHIW are listed in Appendix F of this Chapter.

"Non-contaminated stormwater" means:

(A)

stormwater that has not come into direct contact with solid waste, waste

handling and/or treatment areas;

(B)

stormwater discharging from areas of a land disposal facility that has at least six

inches of waste-free, compacted earthen material; and

(C)

wastewater resulting from washing vehicles or areas that have not been in direct

contact with solid waste.

"Oklahoma Uniform Environmental Permitting Act" means 27AO.S.§ 2-14-101 et seq. and

the rules adopted thereunder at OAC 252:4 ("Rules of Practice and Procedure").

"Open burning" means the combustion of solid waste without:

(A)

control of combustion air to maintain adequate temperature for efficient combustion;

(B)

containment of the combustion reaction in an enclosed device to provide sufficient

residence time and mixing for complete combustion; and

(C)

control of the emission of the combustion products.

"Operating record" means all of the collective records of the facility relating to the site. Such

records include, but are not limited to: the permit, modifications, and approvals; records concerning

waste received; any sampling or analyses performed by the facility; closure, post-closure and

corrective action plans; financial assurance records; inspection and compliance evaluation

correspondence; reports; and scale tickets and related fee payment documentation.

"Owner/operator" means the person who owns a solid waste disposal facility and/or is

responsible for the overall operation of a facility or part of a facility.

"OWRB" means the Oklahoma Water Resources Board.

"Permit boundary" means the outermost edge of the area described by legal description in the

owner/operator's permit. The permitted boundary includes the area in the buffer zone.

"PFLT" means Paint Filter Liquids Test, EPA Method 9095.

"Phased closure" means the closing of individual disposal cells at a land disposal facility as

they become full. Phased closure is not synonymous with final closure.

"Piezometer" means a small-diameter well used to make ground water elevation

measurements.

"Point source discharge" means any discharge of water that, when leaving the permit

boundary of a facility, has been channeled or altered by man's activity in working that site.

"Poor foundation conditions" means those areas where features exist which indicate that a

natural or man-induced event may result in inadequate foundation support for the structural

components of a land disposal facility.

"POTW" means Publicly Owned Treatment Works; a wastewater treatment system, as defined

at 27A O.S. § 2-6-101(9), that is owned by a State or municipality for the treatment of municipal or

industrial wastewaters.

"Qualified groundwater scientist" means a scientist or engineer who has received a

baccalaureate or post-graduate degree in the natural sciences or engineering and has sufficient

6

training and experience in ground water hydrology and related fields as maybe demonstrated by

State registration, professional Certifications, or completion of accredited university programs that

enable that individual to make sound professional judgments regarding groundwater monitoring,

contaminant fate and transport, and corrective action.

"Recharge area" means an area where water is absorbed and added to the zone of saturation.

"Regulated medical waste" means a waste or reusable material that contains an etiologic agent

and is generated in the diagnosis, treatment or immunization of human beings or animals; research

pertaining to the diagnosis, treatment or immunization of human beings or animals; or the

production or testing of biological products. Such waste includes, but is not limited to:

(A)

cultures and stocks of etiologic agents or live vaccines, and culture dishes, devices,

paper, and cloth that has come into contact with such cultures, stocks or live vaccines;

(B)

human blood, blood products, and human body fluids, except urine or feces;

(C)

pathological wastes consisting of human tissues, organs, and body parts removed

during surgery, autopsy, biopsy and other medical procedures;

(D)

untreated sharps;

(E)

used blood collection bags, tubes, and vials;

(F)

contaminated carcasses, body parts and bedding of animals intentionally exposed to

pathogens in research, in the production of biologicals or the "in vivo" testing of

pharmaceuticals;

(G)

items contaminated with blood or other human body fluids which drip freely or would

release such materials in a liquid or semi-liquid state if compressed or are caked with dried

blood or body fluids and are capable of releasing these materials;

(H)

isolation wastes unless determined to be non-infectious by the infection control

committee at the health care facility;

(I)

HIV-containing cell or tissue cultures, organ cultures, and HIV- or HBV-containing

culture medium or other solutions; and blood, organs, or other tissues from experimental

animals infected with HIV or HBV;

(J)

all disposable materials that have come in contact with cytotoxic or antineoplastic agents

during the preparation, handling, and administration of such agents. Such wastes include,

but are not limited to, masks, gloves, gowns, empty IV tubing and bags, vials, and other

contaminated materials; and

(K)

any other material or equipment which, in the determination of the health care facility

staff, infection control committee or other responsible party, presents a significant danger of

infection because it is contaminated with, or may reasonably be expected to be contaminated

with, etiologic agents.

"Residential lead-based paint waste" means lead-based paint debris, chips, dust, sludges, and

other similar wastes generated as a result of abatement, rehabilitation, renovation, or remodeling

activities in individual residences.

"Run-off" means any rainwater, leachate, or other liquid that drains over land from any part of

a facility.

"Run-on" means any rainwater, leachate, or other liquid that drains over land onto any part of

a facility.

"Saturated zone" means that part of the earth's crust in which all voids are filled with water.

"Scavenging" means the uncontrolled, unorganized sorting, collecting, or removing of solid

waste at the disposal site.

"Seismic impact zone" means an area with a ten percent or greater probability that the

maximum horizontal acceleration in lithified earth material, expressed as a percentage of the earth's

7

gravitational pull (g), will exceed 0.10g in two hundred fifty (250) years;

"Sludge" means the definition found at 27A O.S. § 2-10-401.

"Solid waste" means the definition found at 27A O.S. § 2-10-103.

"Special waste" means those wastes that are not hazardous wastes but because of their nature

or volume, require special or additional handling aside from that given to routine household refuse.

This includes but is not limited to: sludge, septic tank pumpings, grease trap wastes, dead animals,

packing house offal and tankage, waste fats and oils, hatchery wastes, cannery wastes, NHIW, tires,

and asbestos wastes.

"Structural components" mean liners, leachate collection systems, final covers, run-on/run-

off systems, and any other component used in the construction and operation of a land disposal

facility that is necessary for protection of human health and the environment.

"Surface impoundment" means a natural topographic depression, human-made excavation,

or diked area formed primarily of earthen materials (although it may be lined with man-made

materials), that is designed to hold an accumulation of liquid wastes or wastes containing free liquids

and that is not an injection well. Examples of surface impoundments are holding, storage, settling,

and aeration pits, ponds, and lagoons.

"Surface water" means water that stands on the surface of the land in reservoirs, lakes, ponds,

sloughs, or swamps, or that flows across the land in rivers, creeks, or streams.

"SW-846" means EPA Publication SW-846, Test Methods for the Evaluation of Solid Waste

Physical/Chemical Characteristics.

"Tremie pipe" means a device, usually a small-diameter flexible or rigid pipe, that carries filter

pack or bentonite cement from the bottom to the top of a borehole or annular space without forming

void spaces. In some cases, a well casing or hollow stem auger can be considered a tremie pipe.

"Unstable area" means a location that is susceptible to natural or human-induced events or

forces capable of impairing the integrity of some or all of the structural components responsible for

preventing releases from a land disposal facility. Unstable areas can include poor foundation

conditions, areas susceptible to mass movements, and Karst terrains.

"Uppermost aquifer" means the geologic formation nearest the natural ground surface that is

an aquifer, as well as lower aquifers that are hydraulically interconnected with this aquifer within

the facility's property boundary.

"Used Tire Recycling Facility" means the definition found at 27A O.S. § 2-11-401.1(15).

"Waste pile" means any non-containerized accumulation of solid, non-flowing waste.

"Waters of the state" means the definition found at 27A O.S. §1-1-201(20).

"Wetlands" mean those areas that are inundated or saturated by surface or groundwater at a

frequency and duration sufficient to support, and that under normal circumstances do support, a

prevalence of vegetation typically adapted for life in saturated soil conditions. Wetlands include,

but are not limited to, swamps, marshes, bogs, and similar areas.

"Working face" means the place within a land disposal facility where waste has been deposited

and has not been covered with at least intermediate cover.

"Yard waste composting facility" means a composting facility that only accepts yard waste.

"Zone of aeration" means a subsurface zone containing water under a pressure lower than that

of the atmosphere, including water held by capillarity; and containing air or gases generally under

atmospheric pressure. This zone is bounded above by the land surface and below by the water table;

and is synonymous with vadose zone and unsaturated zone.

"Zone of saturation" means a subsurface zone in which essentially all the interstices are filled

with water under pressure greater than that of the atmosphere. Although the zone may contain

8

interstices filled with gas or liquids other than water, it is still considered saturated. This zone is

separated from the zone of aeration by the water table and is synonymous with phreatic zone.

252:515-1-3. Terms not defined by Act or rule

Any term not defined in the Oklahoma Solid Waste Management Act, the Oklahoma Used Tire

Recycling Act, or in this Chapter shall be defined by:

(1)

the Dictionary of Geological Terms, Latest Revised Edition, American

Geological Institute;

(2)

EPA RCRA Groundwater Monitoring Technical Enforcement Guidance Document;

(3)

its generally accepted scientific meaning; or

(4)

its standard dictionary meaning.

252:515-1-4. Test methods and map scales

(a)

Test methods. All testing required for compliance with this Chapter shall utilize industry-

standard methods and procedures, unless alternatives are approved in advance by the DEQ.

(1)

Engineering test methods. All engineering tests shall be in accordance with the latest

published ASTM test procedures.

(2)

Water sampling/analyses. Water sampling and analyses methods shall be in accordance

with EPA approved procedures.

(b)

Map scales. Map scale requirements of Subchapter 3, Parts 5 and 7 do not apply when the DEQ

has approved the use of alternative map scales or published maps.

252:515-1-5. Consideration of other laws

All persons and facilities identified in this Chapter may be subject to other state or federal laws and

rules.

252:515-1-6. Severability

The provisions of this Chapter are severable. If any part or provision is held void by a court of

competent jurisdiction, the decision of that court shall not affect or impair any of the remaining parts

or provisions of this Chapter.

252:515-1-7. Beneficial reuse

(a)

Upon request, and with supporting documentation, the DEQ may make a determination that a

waste material is not a solid waste when it can be shown that the material is:

(1)

being used as an ingredient in an industrial process to make a product;

(2)

used as an effective substitute for commercial products;

(3)

being returned to the original process from which it is generated, without first being

reclaimed. The material must be returned as a substitute for raw material feed-stock and the

process must use raw materials as principal feed-stocks; or

(4)

in the possession of persons who actually possess the equipment necessary to process the

material to comply with one of the above conditions.

(b)

The DEQ may also make a reuse determination on other proposals based upon an evaluation of

the contemplated use of the material and potential effects on human health and the environment.

(c)

If waste is accumulated in anticipation of future markets or is stored in a quantity exceeding that

which may be reasonably expected to be used or recycled within one (1) year, the material is

regulated as a solid waste.

9

252:515-1-8. Special considerations

(a)

Existing permits. Permits for active solid waste disposal facilities issued under previous rules,

and those in the post-closure monitoring period on the effective date of this Chapter, remain in

effect.

(b)

[RESERVED]

(c)

[RESERVED]

(d)

MSWLFs prior to October 9, 1991. MSWLFs that stopped receiving waste prior to October

9, 1991 are subject to the final cover and post-closure monitoring requirements of the permit and the

rules in effect at the time of closure.

(e)

MSWLFs on or after October 9, 1991. MSWLFs receiving waste on or after October 9, 1991

are subject to this Subsection.

(1)

Less than 100 tons per day of waste. No later than October 9, 1994, MSWLFs that

received less than an average of 100 tons per day of solid waste after October 9, 1991 and

stopped receiving waste before April 9, 1994 shall install final cover meeting the requirements

of OAC 252:515-19-53.

(A)

Post-closure monitoring requirements. MSWLFs shall be subject to the post-

closure monitoring requirements of the permit and rules in effect at the time of closure.

(B)

Failure to stop accepting waste or to apply final cover. MSWLFs that accepted

waste on or after April 9, 1994, or failed to install the final cover by October 9, 1994 shall

be subject to all applicable requirements of this Chapter.

(2)

100 tons or more per day of waste. No later than October 9, 1994, MSWLFs that received

an average of 100 tons or more per day of solid waste after October 9, 1991 and stopped

receiving waste before October 9, 1993 shall install final cover meeting the requirements of

OAC 252:515-19-53.

(A)

Post-closure monitoring requirements. MSWLFs shall be subject to the post-

closure monitoring requirements of the permit and the rules in effect at the time of closure.

(B)

Failure to stop accepting waste or to apply final cover. MSWLFs that accepted

waste on or after October 9, 1993 or failed to install the final cover by October 9, 1994 shall

be subject to all applicable requirements of this Chapter.

(f)

Other disposal facilities. Other solid waste disposal facilities that stopped receiving waste

prior to the effective date of this Chapter shall close, and perform any applicable post-closure

monitoring, in accordance with the permit and the rules in effect at the time of closure.

(g)

Corrective action. The DEQ may require corrective action any time an inspection of a

solid waste disposal facility or review of testing data indicates the actual release of

contaminants into the environment. Such corrective action shall be performed in accordance

with the requirements of this Chapter.

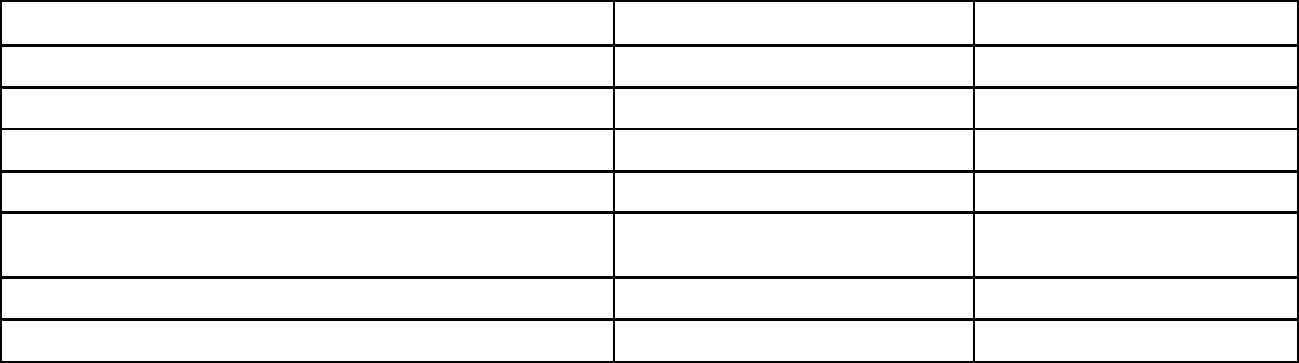

SUBCHAPTER 3. PERMIT PROVISIONS AND APPLICATIONS

PART 1. GENERAL PROVISIONS

Section

252:515-3-1. Permit required

252:515-3-2. Permit not required

252:515-3-3. Prohibition

252:515-3-4. Closed MSWLFs

252:515-3-5. Duration of permit

10

252:515-3-6. Permit transfer

PART 3. PERMIT APPLICATIONS AND MODIFICATIONS

252:515-3-31. General requirements

252:515-3-32. Variance from the rules of this Chapter

252:515-3-33. Oath required

252:515-3-34. Legal right to Property

252:515-3-35. Engineer of record

252:515-3-36. Permit applications

252:515-3-37. Aesthetic enhancement

252:515-3-38. Additional information for land disposal facilities

252:515-3-39. Additional information for waste tire facilities

252:515-3-39.1 Tire Storage permit applications

252:515-3-40. Permits for commercial regulated medical waste processing facilities

252:515-3-41. Permits for the beneficial use, transport, disposal, and storage of sludge

252:515-3-42. Permits for transfer stations

PART 5. REQUIRED MAPS AND DRAWINGS

252:515-3-51. General requirements

252:515-3-52. General location map

252:515-3-53. Flood plain map

252:515-3-54. Quadrangle topographic map

252:515-3-55. Existing contour map

252:515-3-56. Site map

252:515-3-57. Design drawings

PART 7. ADDITIONAL MAPS FOR LAND DISPOSAL FACILITIES

252:515-3-71. General requirements

252:515-3-72. Groundwater resource and usage map

252:515-3-73. Surface geologic map

252:515-3-74. Highest groundwater contour map

252:515-3-75. Potentiometric surface map

252:515-3-76. Site-specific cross sections

252:515-3-77. Fill cross section map

252:515-3-78. Excavation contour map

252:515-3-79. Top of liner contour map

252:515-3-80. Completion map

PART 1. GENERAL PROVISIONS

252:515-3-1. Permit required

(a)

Solid waste disposal facilities. The following solid waste disposal facilities are subject to the

requirements of this Subchapter and require a solid waste permit from DEQ prior to construction

and/or operation:

(1)

land disposal facilities;

11

(2)

solid waste processing facilities, including:

(A)

transfer stations;

(B)

solid waste incinerators receiving waste from off-site sources;

(C)

regulated medical waste processing facilities receiving waste from off-site

sources, and that are not shared service facilities;

(D)

used tire facilities;

(E)

composting facilities, except special events composting facilities and other facilities

exempted by OAC 252:515-43-31;

(F)

permanently established household hazardous waste collection facilities; and

(G)

any other type of facility that processes solid waste;

(3)

facilities used for the storage of solid waste for longer than 10 days; and

(4)

facilities used for the storage of more than 50 used tires, except as authorized by 27A O.S.

§ 2-11-401.7.

(b)

Sludge. Solid waste disposal facilities used for the beneficial use, transport, disposal, or storage

of sludge that is not subject to the direct jurisdiction of any other environmental regulatory agency

of the State of Oklahoma shall obtain a permit in accordance with OAC 252:515-3-41.

252:515-3-2. Permit not required

(a)

The following do not require a solid waste permit and are not subject to the requirements of this

Subchapter, but may be subject to other DEQ permits or requirements:

(1)

rock and dirt fills that receive only uncontaminated rock, dirt, concrete, bricks or

solidified asphalt;

(2)

disposal sites used by a person for disposal of solid waste from his or her household,

provided:

(A)

the disposal site is on land owned by that person;

(B)

the solid waste does not originate from business or commercial activities; and

(C)

such disposal does not violate any local government ordinance or create a

nuisance or hazard to public health or the environment;

(3)

emergency disposal sites approved by DEQ when a natural disaster creates a

need for additional public solid waste disposal sites in the disaster area;

(4)

on-site incinerators meeting the exemption requirements of 27A O.S. § 2-10-501(K);

(5)

on-site regulated medical waste treatment activities by hospitals, clinics, or

laboratories, or other similar facilities for treatment of regulated medical wastes generated on-

site;

(6)

facilities that accept only source-separated recyclable materials for recycling;

(7)

persons under a DEQ order to remediate an abandoned or inactive waste site in

accordance with 27A O.S. § 2-10-301(H);

(8)

facilities used as:

(A)

a citizen collection station;

(B)

a collection and processing point for source-separated, non-putrescible, recyclable

wastes;

(C)

a collection point for parking lot or street sweepings; or

(9)

a collection point for wastes collected and received in sealed bags from such

activities as periodic cleanup campaigns for cities, rights-of-way, or roadside

parks; projects approved by DEQ and a local conservation district in accordance

with 27A O.S. § 2-10-301(J).

(b)

Special events composting facilities operated in accordance with a plan approved by DEQ are

12

not subject to this Subchapter. The plan shall include, at a minimum:

(1)

the permit application information identified in OAC 252:515-3-36(a)(1) through (a)(8);

(2)

a demonstration of compliance with the location restrictions of Subchapter 5 of this Chapter;

and

(3)

a demonstration of how the facility will comply with applicable regulations of other state

agencies or parts thereof, including the Water Quality Division of DEQ.

(c)

Units of local or county government wishing to use baled used tires in engineering projects are

not subject to this Subchapter but must have a plan meeting the requirements of OAC 252:515-21-

111 approved by DEQ prior to beginning the project.

252:515-3-3. Prohibition

Except as provided in OAC 252:515-3-2, no person shall dispose of solid waste at any facility for

which a solid waste permit has not been issued by the DEQ.

252:515-3-4. Closed MSWLFs

MSWLFs that stopped receiving waste on or before April 9, 1994 may receive a modification of

the permit only for operation of a solid waste transfer station, a yard-waste composting facility, or

a citizen collection station.

252:515-3-5. Duration of permit

(a)

Life of site. Permits shall be issued for the life of the disposal facility, subject to the limitations

of (b) of this Section.

(b)

Commencement of construction and operation. DEQ may specify timelines within permits

for commencement of construction and operation of new disposal facilities.

(c)

Cessation of operations. If a permitted active disposal facility ceases to accept waste for 30

days or more without prior notice to the DEQ, the facility is deemed to be in the process of final

closure.

(d)

Suspended operations. Development or operations of a disposal facility may be suspended.

To do so, the owner/operator must provide prior written notice to the DEQ of the intent to suspend

development or operations.

(1)

Suspension of development or operations beyond one year in duration requires DEQ

approval and annual renewal;

(2)

if site development or operations remain suspended for more than one year, without DEQ

approval to continue suspension, the facility is deemed to be in the process of final closure and

must perform closure and post-closure activities in accordance with the approved closure and

post-closure plans, and Subchapter 25 of this Chapter; and

(3)

if financial assurance is required, post full financial assurance in accordance with Subchapter

27 of this Chapter and the approved cost estimates.

(e)

Resuming operations. If facility operations cease pursuant to (c) or (d) of this Section, then

prior to resuming such operations, the permit must be modified if, in the opinion of the DEQ, the

permit does not comply with all current laws and regulations.

252:515-3-6. Permit transfer

(a)

Transfer required. If the ownership of a disposal facility is assumed by a new entity, the

permit must be transferred from the previous owner/operator ("transferor") to the new

owner/operator ("transferee").

(b)

Exception. Changes in corporate ownership from majority stock transfers do not require a

13

permit transfer. However, such changes require notice to DEQ and submittal of an approved

disclosure statement meeting the requirements of OAC 252:515-3-31(g).

(c)

Transfer requirements. Permits may be transferred from the transferor to the transferee upon

the following conditions:

(1)

the transferor has submitted a written request to DEQ for transfer of the permit to the

transferee;

(2)

the transferee has submitted an approved disclosure statement meeting the requirements of

OAC 252:515-3-31(g);

(3)

the transferee has, if required, established an approved financial assurance mechanism in an

appropriate amount and appropriately funded;

(4)

the transferee has agreed in writing to comply with:

(A)

all permit conditions;

(B)

approved plans and specifications;

(C)

the Oklahoma Solid Waste Management Act and/or Used Tire Recycling Act, as

applicable;

(D)

the rules in this Chapter; and

(E)

any final orders issued pursuant thereto;

(5)

the transferee has complied with OAC 252:515-3-33 (relating to oath required); and

(6)

the facility meets the compliance requirements of OAC 252:4-7-15. In lieu of demonstrating

substantial compliance, the parties to the transfer may enter into a Consent Order with DEQ to

schedule compliance.

(d)

Transferor responsible. Until such time as DEQ approves transfer of the permit

to the transferee, the transferor shall remain responsible for the operation of the facility.

PART 3. PERMIT APPLICATIONS AND MODIFICATIONS

252:515-3-31. General requirements

(a)

All permit applications. All permit applications are subject to the Oklahoma Uniform

Environmental Permitting Act as well as the requirements of this Subchapter.

(b)

New permit applications. Applicants requesting a permit fora new solid waste disposal

facility shall submit a permit application to the DEQ meeting the requirements of this Subchapter.

(c)

Modifications required.

(1)

The permit must be modified before making any changes to the approved design,

construction, or operation of the facility.

(2)

The modification application shall contain any maps, drawings, plans or other documents

identified in this Subchapter to ensure the modification will be in compliance with the

applicable requirements of this Chapter.

(d)

Administrative correction. The DEQ may make administrative corrections to the permit.

(e)

Tier I and II permit modifications. Applicants requesting a Tier I or Tier II modification of

an existing permit shall submit a permit modification application to the DEQ meeting the applicable

requirements of this Subchapter, but are not required to comply with OAC 252:515-3-33 (relating

to oath required), unless otherwise required by statute.

(f)

Tier III permit modifications. Applicants requesting a Tier III modification of an existing

permit shall submit a permit modification application to the DEQ meeting the applicable

requirements of this Subchapter, and comply with OAC 252:515-3-33.

(g)

Disclosure statement. Persons submitting a permit application for a new solid waste disposal

facility, or the transfer of an existing solid waste permit, are subject to the disclosure statement

14

requirements of 27A O.S. §§ 2-10-103 and 2-10-302.

(h)

Permits for receipt of NHIW. The following cannot receive a permit to accept NHIW unless

the facility meets the requirements of 27A O.S. § 2-10-501(A):

(1)

new land disposal facilities; and

(2)

existing land disposal facilities that were not authorized to accept NHIW as of the effective

date of this Chapter.

252:515-3-32. Variance from the rules of this Chapter

(a)

Application. Except as provided for in (c) of this Section, applicants may, in a permit

application, request a variance from one or more provisions of this Chapter in accordance with 27A

O.S. § 2-10-304.

(b)

Technical considerations. Applicants requesting a variance must demonstrate that operations

under the variance will equal or exceed the protection accorded by the particular rule for which the

variance is being requested, and will not result in a hazard to the health, environment or safety of the

people of this State or their property.

(c)

Exceptions.

(1)

A variance from the following restrictions of Subchapter 5 of this Chapter shall not be

granted for MSWLFs or NHIW landfills: public water supply(OAC 252:515-5-32(b)), wellhead

protection area (OAC 252:515-5-32(c)), airports (OAC 252:515-5-52(e)), fault areas (OAC

252:515-5-52(b)), seismic impact zones (OAC 252:515-5-52(c)), or unstable areas (OAC

252:515-5-52(d)).

(2)

The DEQ may grant a variance from the 100-year flood plain restriction in accordance with

OAC 252:515-5-32(a)(2).

252:515-3-33. Oath required

The applicant shall sign the permit application under oath on forms provided by the DEQ.

252:515-3-34. Legal right to property

(a)

Right of access. The permit application for a new solid waste disposal facility, or expansion of

the permit boundaries of an existing solid waste disposal facility, must contain:

(1)

a true and correct copy of a legal document filed in the county in which the facility is located,

demonstrating that the applicant possesses a legal right to access and use the property in the

manner for which the permit is sought, including any on- or off-site soil borrow areas,

throughout the life of the site and the required post-closure monitoring period; and

(2)

a certification, by affidavit, that the applicant owns the real property, has a current lease or

easement which is given to accomplish the permitted purpose, or has provided legal notice to the

landowner.

(b)

Option for use. If an option for right of access is predicated upon the issuance of a permit prior

to the exercise of that option, then the applicant must submit a copy of the option with the permit

application. Once the permit has been issued, the applicant must comply with (a) of this Section

prior to beginning construction.

(c)

Easement to the DEQ. Unless the property owner is a unit of government, a temporary

easement shall be executed allowing the DEQ and/or its contractors the right to access the property

to perform closure, post-closure monitoring, or corrective action in the event of default by the

owner/operator.

15

252:515-3-35. Engineer of record

(a)

Professional engineer seal required. Maps, drawings, surveys, calculations, information and

data submitted in support of permit applications for new solid waste disposal facilities or

modifications of existing permits, must be prepared and stamped or sealed by a professional

engineer licensed in the State of Oklahoma if the facility serves a population equivalent of 5,000

persons or more.

(b)

Seal placement. The engineer's stamp or seal shall be placed on the application page. Each map

and drawing included in the application shall be stamped or sealed in accordance with the

requirements of the State Board of Registration for Professional Engineers and Land Surveyors.

(c)

Failure to seal. Documents that are not stamped or sealed in accordance with this Section will

be returned to the applicant.

252:515-3-36. Permit applications

(a)

New applications. A permit application for a new solid waste disposal facility shall include all

information required by the Oklahoma Uniform Environmental Permitting Act, including:

(1)

the owner/operator's name, mailing address and phone number;

(2)

the name by which the facility will be known, the mailing address of the facility, the street

address of the facility (if different from the mailing address), and the facility phone number;

(3)

a disclosure statement completed in accordance with OAC 252:515-3-31(g);

(4)

a legal description, by metes and bounds; section, township, and range, or parts thereof; or

book and page number of plat records for platted property, of:

(A)

the proposed permit boundary;

(B)

the proposed waste processing and/or disposal areas; and

(C)

both on- and off-site soil borrow areas, if applicable;

(5)

latitude and longitude of all corners of the permit boundary and the facility entrance;

(6)

the location of the site from the nearest town or city;

(7)

a description of all processing, storage and disposal operations and units;

(8)

a description of the anticipated waste streams and amount received per day;

(9)

the names of municipalities and/or counties included in the service area;

(10)

the estimated population served, to be determined as follows:

(A)

the population of each town or city served by the disposal facility, as published in the last

decennial census; or

(B)

the population equivalent served, calculated by dividing the anticipated amount of

waste received per day by 4.4 pounds per person per day;

(11)

the types of road construction and materials to be used to ensure that all access roads

within the site are passable during inclement weather by normal vehicular traffic;

(12)

a list of anticipated heavy equipment to be used in the construction and operation of the

site;

(13)

maps and drawings as required by Parts 5 and/or 7 of this Subchapter; and

(14)

data, plans, and specifications for the following:

(A)

a demonstration the proposed facility meets the location restrictions of Subchapter 5

of this Chapter; an operational plan describing how compliance with the operational

requirements of Subchapter 19 of this Chapter, as applicable to the proposed facility, will

be achieved;

(B)

a plan describing how compliance with the stormwater management requirements of

Subchapter 17 of this Chapter will be achieved;

(C)

plans for closure of the facility in accordance with Subchapter 25 of this Chapter; and

16

(D)

a plan for achieving compliance with the aesthetic enhancement requirements of OAC

252:515-3-37; and

(15)

establishment of financial assurance in accordance with Subchapter 27 of this Chapter.

(b)

Information not identified. The DEQ may require the applicant to submit additional data,

revise design specifications or propose environmental safeguards as necessary to meet DEQ rules

for the protection of human health and the environment.

(c)

Permit modification applications. An applicant requesting a modification to an existing

permit shall submit information identified in this Part related to the proposed modification.

252:515-3-37. Aesthetic enhancement

Applications for new permits or expansions of an existing permit boundary, shall include plans

to enhance the visual harmony of the new disposal facility or the expansion area with the

surrounding area, and reduce the transmission of dust and noise from the facility. Such plans may

include placement of berms, fences, shrubbery, trees, or other such materials to achieve the desired

result.

252:515-3-38. Additional information for land disposal facilities

In addition to the requirements of OAC 252:515-3-36, permit applications for land disposal

facilities shall contain data, plans, and specifications for the following, as applicable to the proposed

disposal facility:

(1)

performance of a subsurface investigation and installation of a groundwater monitoring

system in accordance with Subchapters 7 and 9 of this Chapter;

(2)

installation of a liner meeting the requirements of Subchapter 11 of this Chapter;

(3)

installation of a leachate collection system meeting the requirements of Subchapter 13 of

this Chapter;

(4)

establishment of an explosive gas monitoring and remediation system in accordance with

Subchapter 15 of this Chapter;

(5)

establishment of a waste exclusion program in accordance with Subchapter 29 of this

Chapter;

(6)

performance of post-closure monitoring in accordance with Subchapter 25 of this Chapter;

and

(7)

the anticipated life of the site as calculated in accordance with OAC 252:515-27-8.

252:515-3-39. Additional information for used tire facilities

In addition to the requirements of OAC 252:515-3-36, permit applications for used tire facilities

shall include the following:

(1)

the intended development, tire processing equipment specifications, and detailed

operational plans for the facility;

(2)

how the facility will be visually screened, including the planting of trees and other

vegetation;

(3)

methods appropriate for the protection of human health and the environment to control

on-site populations of rodents, flies, mosquitoes, or other animals or insects capable of

transmitting disease to humans;

(4)

the use of mosquito monitoring devices to determine the mosquito population, a

determination of whether or not control action is warranted, and plans to implement control

measures as necessary;

(5)

the intended use for the processed tire material, consisting of a detailed statement about the

17

owner/operator's plans to make the processed tire material available and accessible for

recycling, reuse or energy recovery;

(6)

a description of how the processed tire material will be disposed if the intended use ceases

to be a viable option;

(7)

a fire protection plan that includes:

(A)

how the facility will respond to a fire and with what equipment;

(B)

the criteria for calling the fire department;

(C)

accessibility to a fire hydrant with sufficient water pressure to meet the facility's fire

protection needs;

(D)

how to control surface water run-off resulting from fire extinguishing efforts; and

(E)

other relevant information;

(8)

documentation from the local governmental entity responsible for supplying fire protection

for the used tire facility, approving the facility's fire protection plan;

(9)

plans for surface water run-off controls around tire piles and processed tire piles to prevent

surface water runoff. Engineering plans shall also address discharge of run-off under an OPDES

permit or diversion of collected runoff into a POTW or an evaporation pond;

(10)

plans for a storage area that shall not contain more than 250,000 whole tires;

(11)

plans to ensure all 77 counties of Oklahoma are serviced at least once each calendar

quarter; and

(12)

a description of how compliance with the requirements of Parts 3 and 5 of OAC 252:515-

21 (relating to used tire facilities and transportation) will be achieved and maintained.

252:515-3-39.1. Tire storage permit applications

(a)

Permit applications for tire storage permits shall include all information required by OAC

252:4, the Rules of Practice and Procedure, Subchapter 7, Environmental Permit Process, and the

following:

(1)

a disclosure statement completed in accordance with OAC 252:515-3-31(g);

(2)

a legal description, by metes and bounds; section, township, and range, or parts thereof; or

book and page number of plat records for platted property, of:

(A)

the proposed permit boundary; and

(B)

the proposed waste processing and/or disposal areas.

(3)

latitude and longitude of all corners of the permit boundary and the facility entrance;

(4)

the location of the site from the nearest town or city;

(5)

a description of all processing, storage and disposal operations and units;

(6)

establishment of financial assurance in accordance with Subchapter 27 of this Chapter;

(7)

how the tires will be visually screened, including the planting of trees and other vegetation;

(8)

methods appropriate for the protection of human health and the environment to control

on-site populations of rodents, flies, mosquitoes, or other animals or insects capable of

transmitting disease to humans;

(9)

the use of mosquito monitoring devices to determine the mosquito population, a

determination of whether or not control action is warranted, and plans to implement control

measures as necessary;

(10)

a fire protection plan that includes:

(A)

how the facility will respond to a fire and with what equipment;

(B)

the criteria for calling the fire department;

(C)

accessibility to a fire hydrant with sufficient water pressure to meet the facility's fire

protection needs;

18

(D)

how to control surface water run-off resulting from fire extinguishing efforts; and

(E)

other relevant information;

(11)

documentation from the local governmental entity responsible for supplying fire

protection for the facility, approving the facility's fire protection plan;

(12)

plans for surface water run-off controls around tire piles and processed tire piles to

prevent surface water runoff. Engineering plans shall also address discharge of run-off under an

OPDES permit or diversion of collected runoff into a POTW or an evaporation pond; and

(13)

plans for a storage area that shall not contain more than 250,000 whole tires.

(b)

Information not identified. The DEQ may require the applicant to submit additional data,

revise design specifications or propose environmental safeguards as necessary to meet DEQ rules

for the protection of human health and the environment.

(c)

Permit modification applications. An applicant requesting a modification to an existing

permit shall submit information identified in this Part related to the proposed modification.

252:515-3-40. Permits for commercial regulated medical waste processing facilities

In addition to the requirements of OAC 252:515-3-36, permit applications for commercial

regulated medical waste processing facilities shall identify how compliance with the requirements

of Parts 3 and 5 of OAC 252:515-23 (relating to operational requirements for commercial regulated

medical waste processing and incinerating facilities) will be achieved and maintained.

252:515-3-41. Permits for the beneficial use, transport, disposal, and storage of sludge

(a)

Permit required. In lieu of the requirements of this Subchapter, applicants for a permit for the

beneficial use, -transport, disposal, and storage of sludge not subject to the direct jurisdiction of any

other environmental agency of the State of Oklahoma shall comply with the following.

(1)

DEQ consultation. The applicant shall consult with the DEQ prior to submitting an

application for a permit.

(2)

Considerations. Application requirements shall be based on the nature and volume of the

sludge, as well as its proposed management method and location.

(3)

Specific requirements. The application shall comply with OAC 252:515-3-33, 34, 36, and

37.

(b)

Additional requirements. The applicant shall be subject to the requirements of the Oklahoma

Uniform Environmental Permitting Act and may be subject to one or more requirements of this

Subchapter as well as other requirements of this Chapter, other divisions of the DEQ, and/or

additional requirements as deemed necessary by the DEQ.

(c)

DEQ review. After review of the application, the DEQ may require alterations prior to approval.

(d)

Initiation of permitted activities. The applicant shall not begin activities described by the

application until the permit has been issued.

(e)

Recordkeeping. All records related to the project and required by this Section shall be

maintained for a period of at least five years after completion of the project.

252:515-3-42. Permits for transfer stations.

In addition to the requirements of OAC 252:515-3-36, permit applications for transfer stations

shall establish a waste exclusion plan (WEP) in accordance with Subchapter 29 of this Chapter.

PART 5. REQUIRED MAPS AND DRAWINGS

252:515-3-51. General requirements

19

(a)

Applicability. The maps and designs identified in this Part shall be submitted with permit

applications for:

(1)

all new solid waste disposal facilities;

(2)

expansions of permit boundaries of existing solid waste disposal facilities;

(3)

expansions of waste handling or disposal boundaries of existing solid waste disposal

facilities; and

(4)

any other modification to an existing permit where the data originally submitted would be

made ambiguous, inaccurate, or out of date by the proposed modification.

(b)

Additional maps for land disposal facilities. In addition to the maps and designs required by

this Part, the maps identified in Part 7 of this Subchapter shall be submitted with permit applications

for:

(1)

new land disposal facilities;

(2)

expansions of permit boundaries of existing land disposal facilities; and

(3)

expansions of waste disposal boundaries of existing land disposal facilities.

(c)

Illegible. The permit application will be considered administratively incomplete if any maps or

drawings submitted are not legible.

(d)

Map sequence. All maps and designs shall be submitted in the permit application in the

sequence identified.

(e)

Map scale. Unless otherwise identified, all maps submitted as part of a permit application shall

be prepared at a scale of one inch equals one hundred feet (1" = 100'). An alternative scale may be

used with approval of the DEQ.

(f)

Map details.

(1)

All maps shall show as a minimum, legend, title, north arrow, permit boundary, buffer zone,

and boundaries of waste disposal or processing areas.

(2)

If applicable, the locations of ground water monitoring wells and gas monitoring probes

shall be identified.

252:515-3-52. General location map

The permit application shall include a county highway map published by the Oklahoma

Department of Transportation showing the facility location and any airports within six miles of the

facility. If the facility is located within a municipality and a municipal map with better information

is available, then it may be used.

252:515-3-53. Flood plain map

The permit application shall include a flood plain map from one of the following sources

depicting the limits and elevations of any 100-year flood plain on or within one mile of the permit

boundary of the proposed facility or expansion area:

(1)

Flood Insurance Rate maps published by the Federal Emergency Management Agency, or

maps prepared by the U.S. Army Corps of Engineers, Flood Plain Management Services;

Maps of Flood Prone Areas published by the U.S. Geological Survey; or

(2)

site specific determinations by the U.S. Army Corps of Engineers at the request of the

applicant.

252:515-3-54. Quadrangle topographic map

(a)

Required map. The permit application shall include an original U.S. Geological Survey 7.5

minute series topographic quadrangle map.

(1)

If 7.5 minute series maps have not been printed, then 15 minute series may be used.

20

(2)

If the disposal facility is located on the edge of the quadrangle, then adjoining maps shall be

provided.

(b)

Required details. The quadrangle topographic map shall clearly depict:

(1)

the location of the facility permit boundaries;

(2)

access routes within one mile of the facility;

(3)

homes and buildings within one mile of the facility;

(4)

public water and wastewater collection, treatment, and distribution facilities within one mile

of the facility;

(5)

receiving waters and surface variations within one mile of the facility; and

(6)

water wells, including private and municipal, potable and irrigation water within one mile

of the facility.

252:515-3-55. Existing contour map

(a)

Required map. The permit application shall include a constructed map showing the

topographic contours prior to any operations at the facility.

(b)

Contour intervals. The contour interval on the map shall not be greater than two feet.

(c)

Required details. The existing contour map shall show the location and quantities of surface

drainage entering and exiting the facility, and the locations of all boreholes with their surface

elevations.

252:515-3-56. Site map

(a)

Required map. The permit application shall include a site map, which may be the existing

contour map.

(b)

Required details. The site map shall show the following, as applicable to the facility:

(1)

the dimensions of the permit boundary as indicated by legal description;

(2)

the receiving processing, storage or disposal areas;

(3)

buffer zones;

(4)

the locations and surface elevations of each borehole, monitor well, test well, monitoring

site, test pit, sampling site and permanent benchmarks;

(5)

the surface and top of casing elevations for each monitoring well or gas probe;

(6)

the surface drainage, including location of diversion ditches, dikes, dams, pits, ponds,

lagoons, berms, terraces and other relevant information;

(7)

the location of fencing and gates, utility lines, pipelines, and easements;

(8)

the access roads into and on the site;

(9)

employee and equipment shelters; and

(10)

on- and off-site soil borrow areas.

252:515-3-57. Design drawings

The permit application shall include, as necessary, design drawings and specifications for:

(1)

receiving, processing, storage or disposal areas;

(2)

liner construction;

(3)

leachate collection systems;

(4)

typical well installation;

(5)

dike sections;

(6)

drainage channels;

(7)

groundwater monitoring wells, gas monitoring probes, and piezometers;

(8)

retention structures or other groundwater and surface water protection measures; and

21

(9)

any other design drawings or specifications necessary to describe the proposed activities for

the facility.

PART 7. ADDITIONAL MAPS FOR LAND DISPOSAL FACILITIES

252:515-3-71. General requirements

(a)

Applicability. The maps and designs identified in this Part shall be submitted with all permit

applications for a new land disposal facility or expansions of the waste disposal boundaries of an

existing land disposal facility.

(b)

Map requirements. Maps submitted to the DEQ pursuant to the requirements of this Part are

subject to the general map provisions of OAC 252:515-3-51(c) through (f).

252:515-3-72. Groundwater resource and usage map

(a)

Required map. The permit application shall include a groundwater resource and usage map,

made to a scale of 1:6000 (1 inch = 500 feet).

(b)

Required details. The map shall show the following:

(1)

the location, total depth and ground water elevation of all known private water wells within

a radius of one mile of the proposed site boundary;

(2)

the location, total depth and ground water elevation of all public water supply wells within

a radius of two miles of the proposed site boundary; and

(3)

recharge and discharge areas and the description of ground water quality within a three mile

radius of the proposed site boundary.

252:515-3-73. Surface geologic map

The permit application shall include a site-specific areal geologic map depicting the lithologic

units of the ground surface, made to a scale of no smaller than 1:1200 (1 inch = 100 feet).

252:515-3-74. Highest groundwater contour map

(a)

Required map. The permit application shall include a groundwater contour map developed

from the information obtained during the groundwater study required in Part 5 of OAC 252:515-7.

(b)

Required details. The groundwater contour map shall depict:

(1)

the groundwater contours, at two foot intervals, of the highest groundwater elevation ever

recorded at each borehole, piezometer or well across the site. The highest elevation shall be

based on the groundwater levels recorded during the subsurface investigation or any other

record of groundwater elevation measurements; and

(2)

the locations of all proposed monitoring wells, boreholes, and piezometers, and the surface

elevations of each.

252:515-3-75. Potentiometric surface map

(a)

Required map. The permit application shall include an actual groundwater potentiometric

surface map developed from the information obtained during the groundwater study required in Part

5 of OAC 252:515-7.

(b)

Required details. The potentiometric surface map shall depict:

(1)

groundwater elevation contours at two foot intervals as measured in a single time event

reflecting the highest average water level elevation across the site during the 12-month

monitoring period; and

(2)

the locations of all proposed monitoring wells, boreholes, and piezometers, and surface

22

elevations of each.

252:515-3-76. Site-specific cross sections

(a)

Required map. The permit application shall include two site-specific cross sections constructed

from subsurface borehole logs and other site-specific information, such as water well logs, oil and

gas well logs, outcrops at or near the site, and geophysical surveys.

(b)

Orientation. The first cross section shall be oriented parallel to the dip of the underlying strata

and the second oriented perpendicular to the dip of the strata. If this is not possible, the cross-

sections shall be oriented at 90 degrees from each other.

(c)

Required details. Each cross section shall include:

(1)

the borehole logs and other sources of information displayed relative to mean sea level on

the cross section;

(2)

the depth, thickness and areal extent of each stratigraphic unit;

(3)

lithology of significant formations or strata, and unconsolidated sediment type;

(4)

structural features (faults and folds);

(5)

stratigraphic contact between formations or strata, and unconsolidated sediments;

(6)

zones of hydraulic conductivity greater than 1 x 10

-3

cm/sec;

(7)

fracture zones;

(8)

otentiometric surfaces of all confined and unconfined saturated zones;

(9)

location, depth and producing zone of water wells that could be used in the construction of

the cross section;

(10)

the surface upon which the waste will be placed, i.e., the landfill floor or top of liner;

(11)

soils or strata encountered by the boreholes suitable for use as liner material;

(12)

intervals and results of both in-situ and laboratory hydraulic conductivity tests;

(13)

surface water drainage features, such as: dikes, levees, or trenches;

(14)

the existing ground surface and final cover;

(15)

gas extraction wells or probes;

(16)

monitor wells or piezometers; and

(17)

a legend that includes vertical and horizontal scales and a map showing the location of

the boreholes and other information used to construct the cross section.

252:515-3-77. Fill cross section map

(a)

Required map. The permit application shall include a fill cross section map.

(b)

Required details. A grid system shall be established and typical cross sections plotted along

the principal axis and along the minor axis.

(1)

A cross section locator map shall show the grid system superimposed over the site plan with

each cross-section labeled. This drawing may be at any convenient scale and labeled

accordingly.

(2)

Cross section drawings shall depict the elevation(s) of the top of any dikes or levees, the final

cover, wastes, ground surface, the top of liner, the bottom of excavations, the side slopes of

trenches and fill areas, groundwater monitor wells, gas wells or vents, and recorded initial and

static water levels.

(3)

The scale shall be 1:600 (1 inch = 50 feet) horizontal and 1:60 (1 inch = 5 feet) vertical.

(4)

Soil borings may also be shown on the profile.

252:515-3-78. Excavation contour map

The permit application shall include an excavation contour map showing:

23

(1)

contours, at two foot intervals, of the bottom of the proposed excavation;

(2)

the anticipated progression of the construction; and

(3)

the locations and final depth of the boreholes.

252:515-3-79. Top of liner contour map

(a)

Required map. The permit application shall include a top of liner contour map showing:

(1)

contours, at two foot intervals, of the top of the liner; and

(2)

the locations of the proposed monitor wells.

(b)

Liner construction. Details of liner construction may be provided on this map or as a separate

drawing.

252:515-3-80. Completion map

(a)

Required map. The permit application shall include a completion map showing how the new

facility or expansion is expected to look when it is completed, including final contours.

(b)

Required details. The completion map shall include the permit boundary, disposal boundary,

buffer zone, gas and groundwater monitoring well locations, the leachate removal locations,

permanent surface drainage structures and aesthetic enhancements.

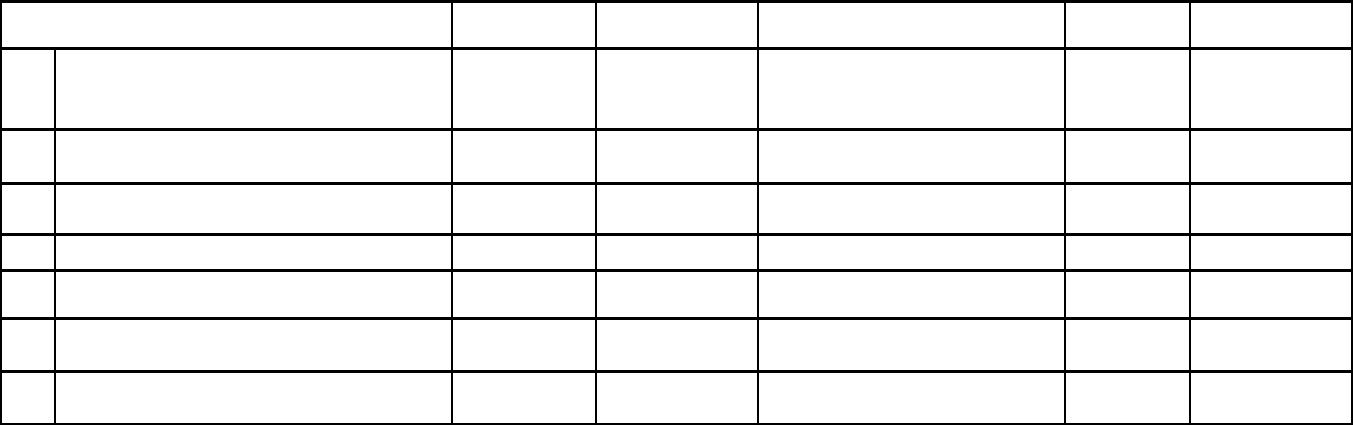

SUBCHAPTER 5. LOCATION RESTRICTIONS

PART 1. GENERAL PROVISIONS

Section

252:515-5-1. Applicability

PART 3. LOCATION RESTRICTIONS FOR ALL SOLID WASTE DISPOSAL

FACILITIES

252:515-5-31. Restrictions on location of permit boundary

252:515-5-32. Restrictions on location of waste management and disposal areas

PART 5. ADDITIONAL LOCATION RESTRICTIONS FOR LAND DISPOSAL

FACILITIES

252:515-5-51. Restrictions on location of permit boundary

252:515-5-52. Restrictions on location of waste management and disposal areas

PART 1. GENERAL PROVISIONS

252:515-5-1. Applicability

(a)

All solid waste disposal facilities. All new and active solid waste disposal facilities are subject

to the location restrictions of Part 3 of this Subchapter.

(b)

Land disposal facilities. In addition to the restrictions of Part 3 of this Subchapter, all new and