NORTHEAST EXTREME TEE (NEXT) BEAM GUIDE DETAILS

These guidelines and guide details have been developed for the purpose of promoting a greater degree of uniformity

among owners, engineers and industry with respect to planning, designing, fabricating and constructing the Northeast

Extreme Tee (NEXT) Beam for bridges.

In response to needs determined by Northeast Transportation Agencies, and Prestressed Concrete Producers, the

PCI Northeast Bridge Technical Committee prepared these guidelines and guide details to promote uniformity of

design and details throughout the region.

The PCI Northeast Bridge Technical Committee Members:

Rita Seraderian PCI Northeast

Michael Culmo CHA Consulting, Inc.

Raymond Basar Connecticut DOT

Bryan Reed Connecticut DOT

Joel Veilleux Maine DOT

Richard Meyers Maine DOT

Taylor Clark Maine DOT

Alex Bardow Mass. DOT

Edmund Newton Mass. DOT (Ret.)

Michael Merlis Mass. DOT

David Scott New Hampshire DOT

Jason Tremblay New Hampshire DOT

Duane Carpenter NYSDOT

Scott Lagace NYSDOT

Ramiz Turan NYSDOT

Adrienne LiBritz-Cooley NYSDOT

Mike Twiss NYSDOT (Ret.)

Mike Savella State of Rhode Island DOT (Ret.)

Stephen Coley VTRANS

Rob Young VTRANS

Brennon Barnard Dailey Precast

Scott Harrigan The Fort Miller Co., Inc.

Joe Carrara J. P. Carrara & Sons

Troy Jenkins Northeast Prestressed Products

Chris Fowler Oldcastle Precast

Bruce Miller Unistress Corp.

James Cutler Unistress Corp.

Chris Moore United Concrete Precast

Bill Augustus United Concrete Precast

Eric Calderwood Calderwood Eng.

John Byatt Fuss & O'Neill

Ben Cota GCP Applied Tech

Paul Moyer Gill Engineering

Darren Conboy Jacobs Engineering

Ed Barwicki Lin Associates

Sergio Brena University of Mass.

The details shown are guidelines and should not be considered standards.

The information has been obtained from sources believed to be reliable. PCI

Northeast or its membership shall not be responsible for any errors, omissions

or damages arising out of this information. PCI Northeast has published this

work with the understanding that PCI Northeast is supplying information only.

PCI Northeast is not rendering engineering or other professional services

through this guideline. If such services are required, please seek an

appropriate professional.

WWW.PCINE.ORG

Report Number:

PCINER-12-NEXT

Copyright 2020

By: Precast/Prestressed Concrete Institute Northeast

Northeast Extreme Tee (NEXT) Beam Guide Details

Second Edition 2021

Issue Date: 1/22/2021

All rights reserved. This guide or any part thereof may

not be reproduced in any form without the written

permission of the Precast/Prestressed Concrete Institute

Northeast.

Page i

NEXT Beam Frequently Asked Questions

General Questions

1. Is the NEXT Beam Proprietary?

The NEXT Beam is a regional standard that was developed by the northeast state departments of

transportation, consultants, and fabricators. Similar to other standard bridge sections, it is

available from multiple fabricators and it is not proprietary.

2. Who supplies the NEXT Beam?

The NEXT Beam is produced by many PCI Certified precast producers. Contact your local PCI

Regional Association or local producer.

3. Is the NEXT Beam acceptable to bridge owner agencies?

Yes. The NEXT Beam was developed by a consortium of state bridge engineers from all six New

England states and New York and members of the Northeast region of PCI. In addition, many

other DOT bridge offices in the United States are using the beam.

4. Is the NEXT Beam more economical than other bridge systems?

The NEXT Beam is efficiently designed to minimize labor in both the manufacturing plant and at

the job site. The lack of draped (harped) strands is a significant benefit during fabrication. The

elimination of deck forming in the field saves significant time during construction, and also provides

an instant platform for work, making for a much safer project. NEXT beam bridges are a cost-

effective structure and have reduced the overall cost of building bridges in the Northeast.

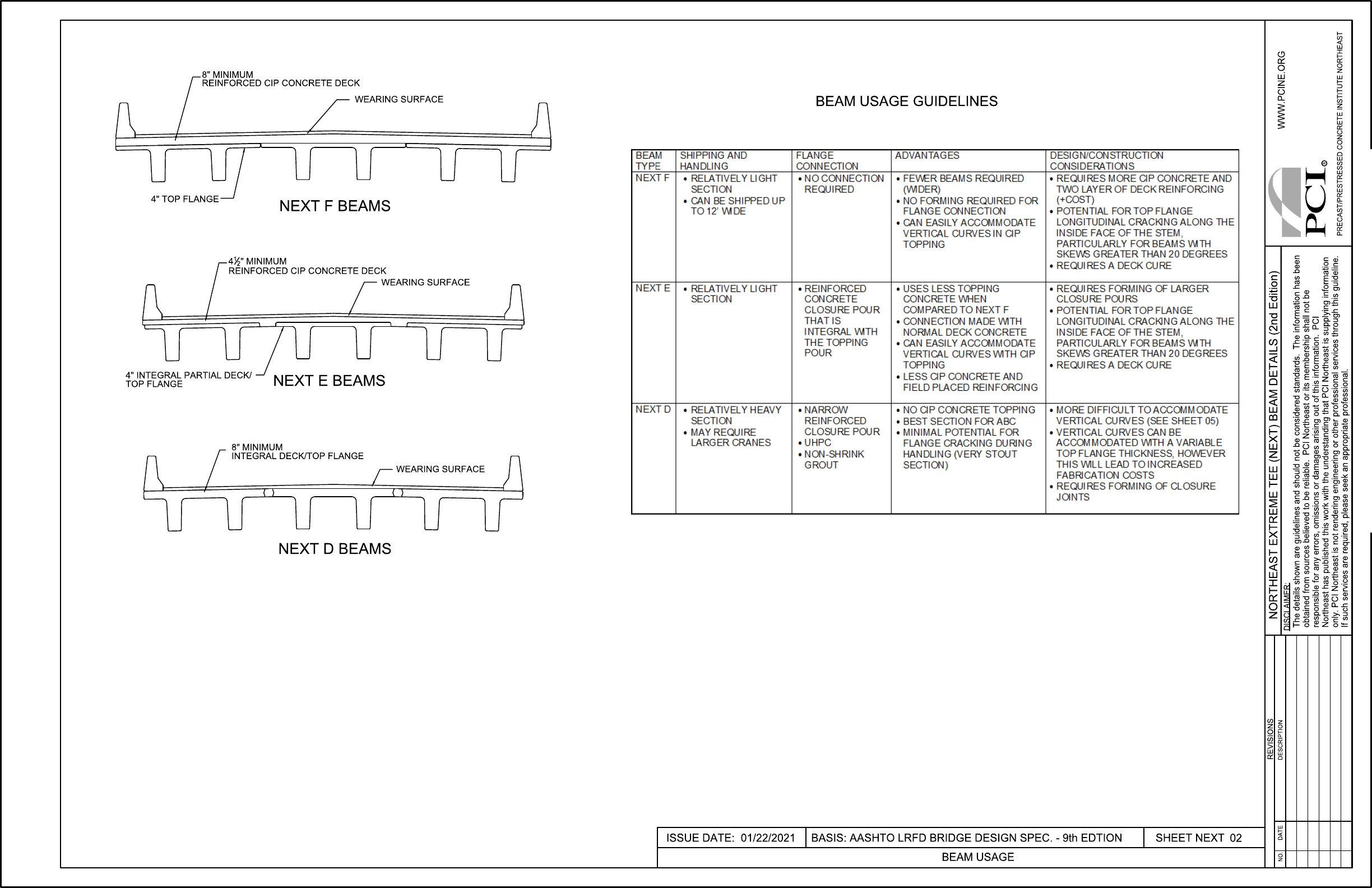

5. What is the difference between the D, E and F Beam?

• The D Beam (Deck Beam) is a beam with an integral full-depth flange that acts as the

structural bridge deck. This allows the bridge to be ready for traffic soon after the beams are

erected.

• The F Beam (Flange Beam) is a beam with a partial-depth flange, which serves as the

formwork for a conventional cast-in-place reinforced concrete deck. This results in a

monolithic deck surface at the expense of a few extra days of site construction. The top flange

of the F Beam eliminates the need for deck forming (including the overhang), which is a

tremendous time saver.

• The E Beam (Deck/Flange Beam) is a beam that has a top flange that is intended to act as

the bottom portion of the structural deck. A reinforced cast-in-place concrete topping is used

to complete the structural deck, which will reduce the amount of CIP deck concrete in the field

from approximately 8” to 4”. The top flange of the NEXT Beam eliminates the need for deck

forming (including the overhang),

6. How do I handle utilities on my bridge?

One of the main reasons the NEXT beam was developed was to handle multiple utilities, unlike

the box beam, which can only accommodate a few. Utility supports can be coordinated with the

Manufacturer and be cast into the beam at the time of fabrication to expedite installation time out

in the field.

7. Are diaphragms required?

Intermediate diaphragms are not required for the NEXT Beams. AASHTO LRFD Bridge Design

Specifications require diaphragms at the supports where there is a joint in the deck.

8. What is the recommended bearing type?

NEXT Beams are typically supported on reinforced elastomeric bearing pads. Details have been

developed and are found on Detail Sheet NEXT 15 of the guidelines. Bearings that can be

adjusted vertically may be beneficial for complex geometries. For example, on a skewed bridge

with a vertical curve, the support points are out of plane, creating the need for a variable 4-point

support system. The adjustable bearing will solve this problem.

Bridge Geometry Questions

1. What are the typical span lengths and widths?

The NEXT Beam can range from a length of 30’ to 80’ and a nominal width of 8’ to 12’ for the

NEXT F beams, 8’ to 10’ for the NEXT D Beams and 8’ to 9.5’ for NEXT E. These span ranges

are approximate since they are based on certain design parameters such as parapet weight and

overlay options. Actual span capabilities should be checked for each situation based on the actual

design parameters. Please consult the attached Detail Sheets.

2. Can NEXT Beam be used for a skewed bridge?

Yes. PCI Northeast recommends a maximum skew for each beam type (AASHTO skew convention)

but it may be possible to exceed this value (the largest skew built has been 45 degrees). The

concern is with regard to cracking at release in the fabrication plant. Experience with double tee

beams has shown the potential for longitudinal cracking in the top flange near the interior stem

surfaces. Additional reinforcement has been placed in this region; however, the potential for the

development of these cracks is still present and larger skews would mean longer cracks in the end

zone. Skewed NEXT D beams general have less cracking than NEXT F or E beams due to the 8”

flange and two layers of flange reinforcement. Skewed beams may require special bearing details.

See General Question Number 8.

3. Can the NEXT Beam be used for a curved bridge?

The widths of the NEXT Beams can be adjusted readily in fabrication to accommodate gentle

curves. The flanges of the exterior NEXT Beams can be curved (in plan) to produce a curved

roadway geometry, provided that the flanges fall within the design envelope shown on Detail Sheet

NEXT 01.

4. Can the NEXT Beam be used for a variable width bridge?

The widths of the NEXT Beams can be adjusted readily in fabrication to accommodate roadways

that are tapered in plan. The flange width of the NEXT Beams can be tapered, creating a slightly

‘pie shaped’ beam that would be used for splayed layouts.

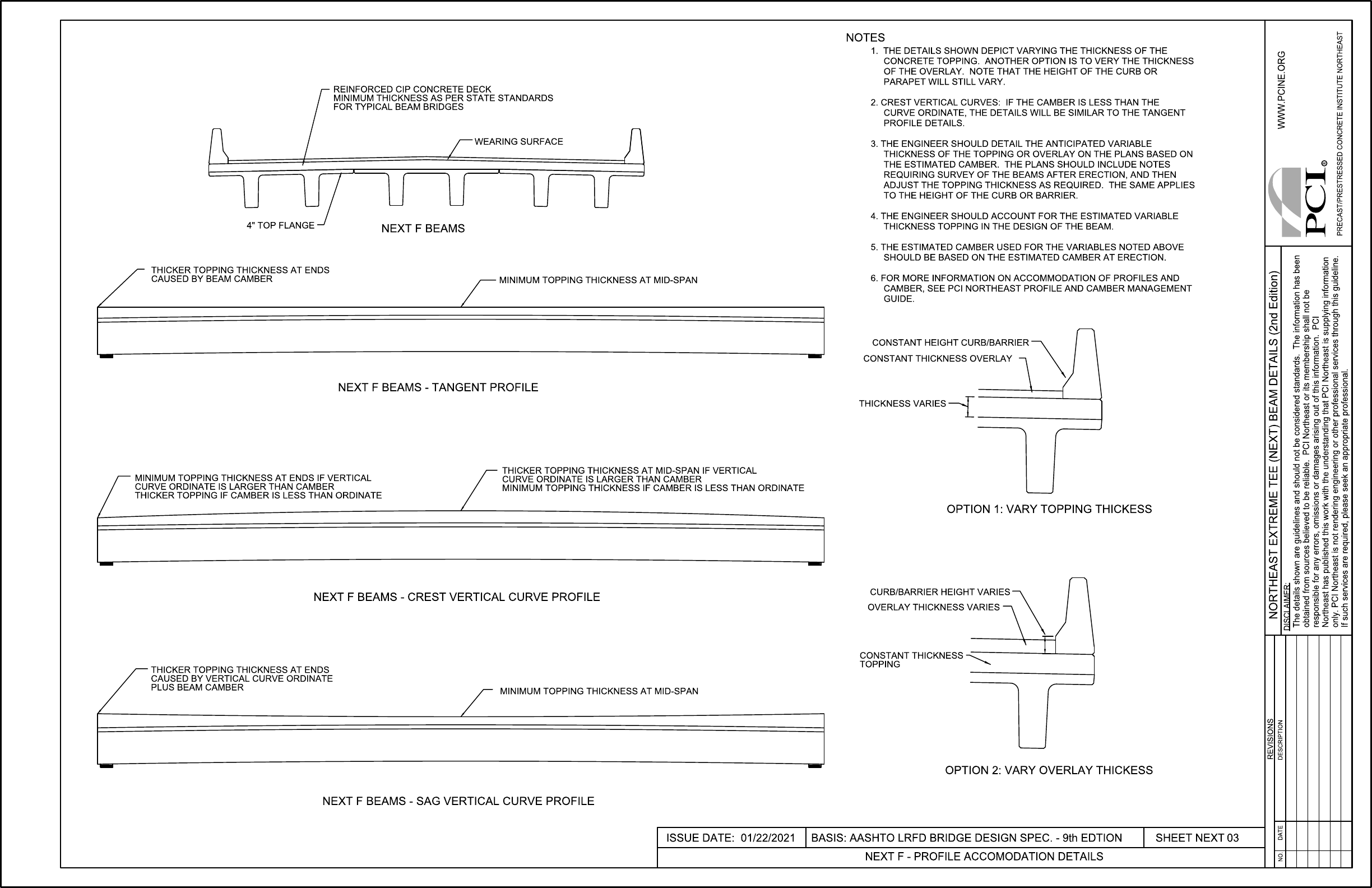

5. How do you accommodate roadway profiles with a cambered NEXT Beam?

The accommodation of roadway profiles with a cambered NEXT beam can be handled in several

ways. The thickness of the deck topping concrete on NEXT E and F Beam bridges can be varied.

The thickness of the top flange on Next D Beams can be varied; however, this comes at a higher

cost due to the need for more complex forming in the fabrication plant. Another option is to vary

the thickness of the overlay (if allowed by state standards) to provide the desired profile. See Profile

Details on Detail Sheets NEXT 03 through 05.

6. How do you accommodate roadway cross slopes and crowns?

The beams can be set to match the roadway cross slope. This is not normally done with

prestressed I-Beams due to issues with stability. The large lateral stiffness of the NEXT Beam

allows for this approach, which greatly simplifies the installation. Roadway crowns can be

accommodated at the joints between the beams, or within the topping or overlay. See Detail Sheet

NEXT 08.

7. Is it possible to design NEXT Beam that is narrower than the 8-foot minimum?

The 8-foot minimum was set to provide relatively equal stem spacing (within 2 feet), to provide

room for inspection access of the stems between the beams, and to avoid impacting the curved

fillet on the underside of the top flange. A minor reduction from this minimum can be used with

permission from the owner.

8. Is it possible to design half section single tee using the NEXT Beam Form?

It is possible to use a half section for cases where a specific bridge width is required or for bridges

were staged construction does not permit full width sections.

9. Is it possible to step (dap) the bottom of the stem at the support?

This should only be done for special situations where the height of the bridge seat must be raised

(i.e. low clearance straddle bent). Special care should be exercised in the design to prevent

cracking in this critical area. The PCI Design Handbook contains a recommended design

procedure for this situation.

Page ii

NEXT Beam Frequently Asked Questions

Design Questions

1. What bridge software can be used to design a NEXT Beam bridge?

Engineers in New England and New York have used PS Beam (www.lrfd.com) to design NEXT

Beam bridges. ConSpan by Leap (www.bentley.com) and PG Super (www.pgsuper.com) are also

viable software packages.

2. Are the span charts on Detail Sheet NEXT 08 acceptable for preliminary design?

The values shown are not guaranteed and should be considered approximate. They are intended

to be used as a starting point for preliminary layout. The actual maximum span lengths are affected

by a number of assumptions, some of which are listed in the notes on Detail Sheet NEXT 08.

Check the assumptions against your project design requirements before selecting a beam size.

During preliminary design and structure type studies, the beams should be checked to ensure that

a section will work.

3. How do I distribute dead and live load to the NEXT beams?

Guidelines for the Live Load Distribution Factors for F, E and D Beams are found on Detail Sheet

NEXT 01.

4. Can I design the beams for continuity?

Yes. This would be done the same way as any prestressed concrete beams. The negative moment

reinforcement can be cast into the deck on the NEXT F or E design. For the NEXT D design,

mechanical couplers could be considered, or the top flange could be dapped with projecting

reinforcing. Care shall be taken with dapping beams. The designer should check stresses in the

dapped area. The positive moment reinforcement could be strand extensions or mild

reinforcement projecting from the stem.

5. How do I design deck reinforcement for a NEXT F Beam Bridge?

The design of the deck is based on a normal stringer bridge. It is recommended that the top flange

not be used in the deck design. The deck can be designed by treating each stem as an individual

beam with the deck spanning between stems.

6. How do I design deck reinforcement for a NEXT D and E Beam Bridge?

The design of the deck is based on a normal stringer bridge. The deck can be designed by treating

each stem as an individual beam with the deck spanning between stems. The reinforcing for the

NEXT D is fully cast into the top flange. The bottom mat reinforcing for the NEXT E is fully cast

into the beam, the top mat is placed in the topping.

7. How do I design the connection between the NEXT D and E Beams?

The connections should be a reinforced moment connection. The design of the connection should

be based on the moments generated using a standard AASHTO strip method. The deck can be

designed by treating each stem as an individual beam with the deck spanning between stems.

Once the positive moment is calculated at the joint, the section can be checked assuming that the

projecting bars are fully developed. The reinforcing shown on the typical details should work for

most scenarios; however, it should be checked for each design.

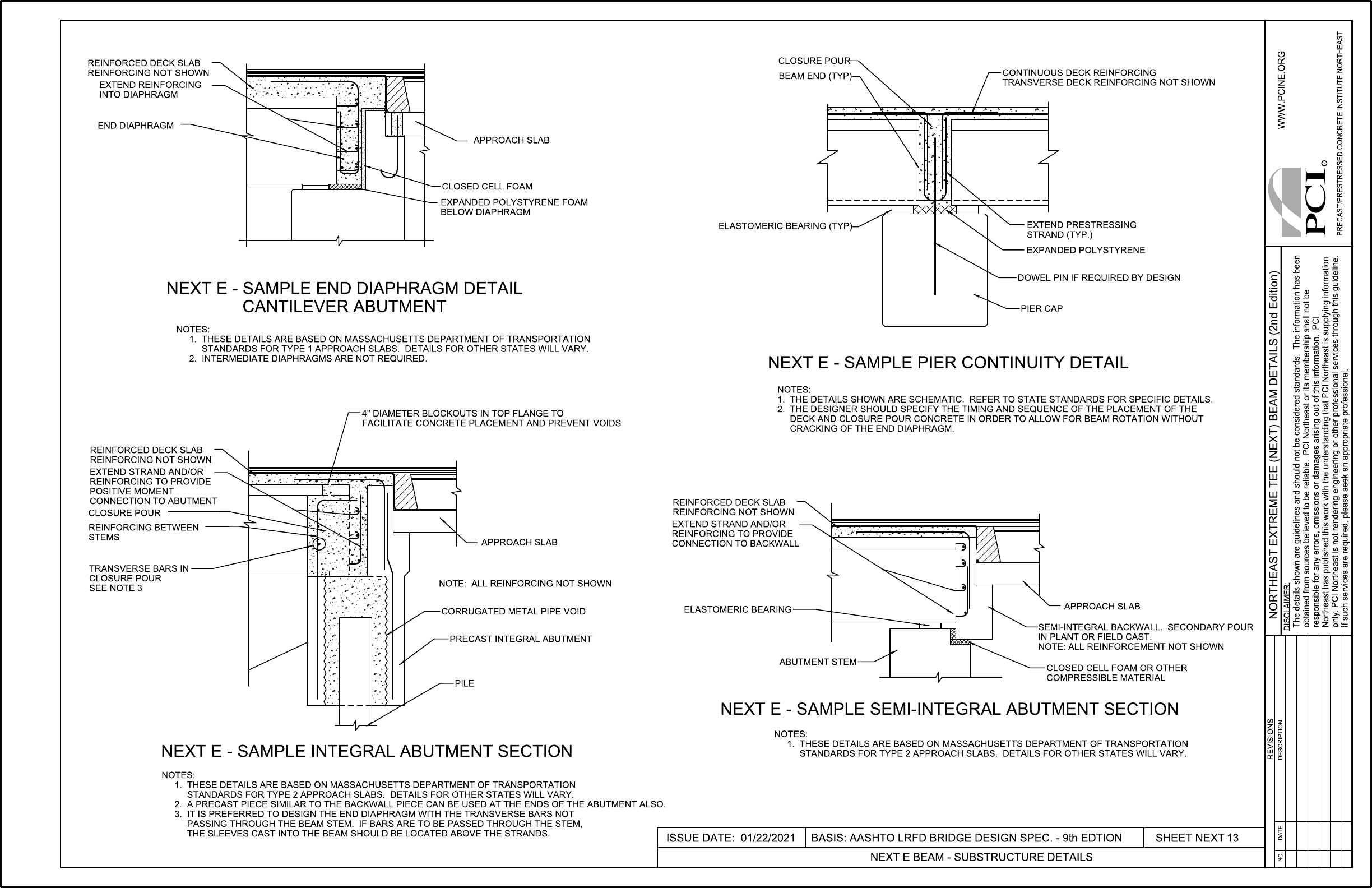

8. How do I design integral abutments using the NEXT beam?

The design of integral abutment bridges using NEXT beams is the same as any stringer bridge.

See Detail Sheets NEXT 12-14.

9. Is post-tensioning required to connect NEXT D Beams (similar to box beams)?

NEXT D Beams have been developed with reinforced closure joints, which eliminates the need to

use transverse post-tensioning to connect the flanges. This meets the AASHTO requirements for

load distribution and is considered to be sufficient to make the beams act as a unit.

10. Some states connect decked beams with welded ties. Is that acceptable for NEXT Beams?

Welded tie connections are common in parking structures but have been found to be inadequate

for truck loading. Most states are changing flange connection details to one similar to those shown

in these guide details.

11. What options are available for connecting the flanges of NEXT D and E Beams?

The details provided allow for multiple options and fill materials. The most common reinforcing

and fill materials are shown on Detail Sheets NEXT 10 and 11. There is also guidance on how to

design and detail the connection with alternate materials, which is based on the AASHTO LRFD

Guide Specifications for Accelerated Bridge Construction. Note that the width of the joint for NEXT

D and E Beams will affect the beam spacing or top flange width.

12. How do you accommodate top tension stresses at the beam ends after release?

First and foremost, the design of the beam needs to conform to individual state design

requirements. Some states require a design with zero tension at release. Others limit the stress

in accordance with the AASHTO LRFD Bridge Design Specifications. It is important to note that

the AASHTO LRFD Bridge Design Specifications require longitudinal reinforcing in the top flange

at beam ends if the top fiber stresses exceed the specified allowable values. These bars are used

to “control” transverse cracking in the top flange at release. This reinforcing is for crack width and

length control, not prevention. It is recommended that if fully tensioned top strand is included in the

design, they should not be used to meet these AASHTO provisions.

13. What is the purpose of the J bar in the corner of the NEXT Beam flange/web intersection?

These bars are used to control top flange end cracking during release and handling. The most

common form of potential cracking in this area is a series of vertical hairline cracks located near

the inside radius of the top flange / beam stem interface running parallel to the stem. The J bars

intersect and are perpendicular to the potential crack plane. End skew of the beams has been

found to exacerbate this issue. The use of a semi-integral backwall or integral end diaphragm that

is cast in the shop as a secondary pour can help to prevent the growth of these cracks during

shipping and erection. This is recommended for bridges with significant skew and if the

recommended maximum skew is to be exceeded.

14. Is confinement reinforcement as specified in the AASHTO LRFD Bridge Design

Specifications required for NEXT Beams?

Most designers have chosen to use an approach similar to box beams, where they use the U-

shaped stirrups in the end regions to meet this provision. Separate enclosed confinement

reinforcement can be used; however, the designer should verify that there is sufficient room in this

end region to accommodate the enclosed hoops.

Page iii

NEXT Beam Frequently Asked Questions

Deck and Wearing Surface Questions

1. How do you seal the longitudinal joints between beams?

Bridges using the F Beam will have a monolithic deck; therefore, there is no need for a flange edge

connection. The D and E Beams have reinforced joints. The design of these joints should be in

accordance with the AASHTO LRFD Guide Specifications for Accelerated Bridge Construction. In

general, the joints are designed to resist the moments and shears calculated using the AASHTO

strip method. The details shown are considered to fully develop the bars on the deck.

2. Why is the side of the keyway detailed with an exposed aggregate surface?

The exposed aggregate surface of the faces of the keys is recommended to improve grout bond

and minimize potential for leakage of the joint. This is consistent with the provisions of the

AASHTO LRFD Guide Specifications for Accelerated Bridge Construction. Note that there is no

amplitude requirement for the roughness of the surface, as long as the aggregate is visible on the

surface. Surface profile amplitude is an AASHTO LRFD Bridge Design Specification provision for

connecting a precast beam to a cast-in-place deck (interface shear). The shape of the shear keys

on NEXT D Beams provides the mechanical shear transfer mechanism, therefore a specific

amplitude is not required.

3. What is the recommended wearing surface?

The NEXT E and F Beam has a composite concrete deck cast on top; therefore, any agency

standard wearing surface treatment can be used, including bare concrete. The NEXT D Beam

has an integral deck cast into the beam. While not necessarily required, a wearing surface (either

thin concrete or bituminous) is recommended in order to provide the smoothest riding surface. If

bituminous wearing surfaces are used, a waterproofing membrane should be applied prior to

paving. Refer to agency standards for acceptable wearing surface options.

Page iv

Railing Questions

1. How are concrete railings (parapets) handled?

The use and details of concrete railings should conform to state standards. The deck overhang

thickness shall be detailed to provide adequate dowel/anchor embedment for the barrier to deck

connection. Deck overhangs supporting railings should be designed for the same provisions used

for a cast-in-place deck. The required additional top reinforcing is placed in the topping for NEXT

F and E beams, and within the top flange for NEXT D beams. .

2. Can metal bridge railings be used on a NEXT D Beam without a cast in place curb?

The use and details of metal railings, with and without curbs, should conform to state standards.

The deck overhang thickness shall be detailed to provide adequate dowel/anchor embedment for

the railing and curb to deck connection. Deck overhangs supporting railings should be designed

for the same provisions used for a cast-in-place deck.

3. How is the variable height of the concrete railing or curb calculated as shown on Detail

Sheet NEXT 03 through 05?

This is a relatively complicated calculation. The designer needs to calculate the estimated heights

based on at least the following variables:

• Roadway profile (tangent, crest vertical curve. or sag vertical curve)

• Estimated beam camber

• Beam seat elevations

• Dead load deflection of the beam

The calculations are similar to those used to calculate beam haunches on prestressed girders with

cast-in-place concrete decks. As with beam haunches, the designer can specify that the beam

edges be surveyed after erection and the barrier or curb heights adjusted based on camber and

construction tolerances.

g

g

s

s

GENERAL NOTES

01

DESIGN AND IMPLEMENTATION GUIDELINES

LIVE LOAD DISTRIBUTION FACTOR CALCULATIONS

GENERAL NOTES

INDEX OF DETAIL SHEETS

MISCELLANEOUS NEXT BEAM DETAILS

NEXT 15

NEXT D BEAM - SUBSTRUCTURE DETAILS

NEXT 14

NEXT E BEAM - SUBSTRUCTURE DETAILS

NEXT 13

NEXT F BEAM - SUBSTRUCTURE DETAILS

NEXT 12

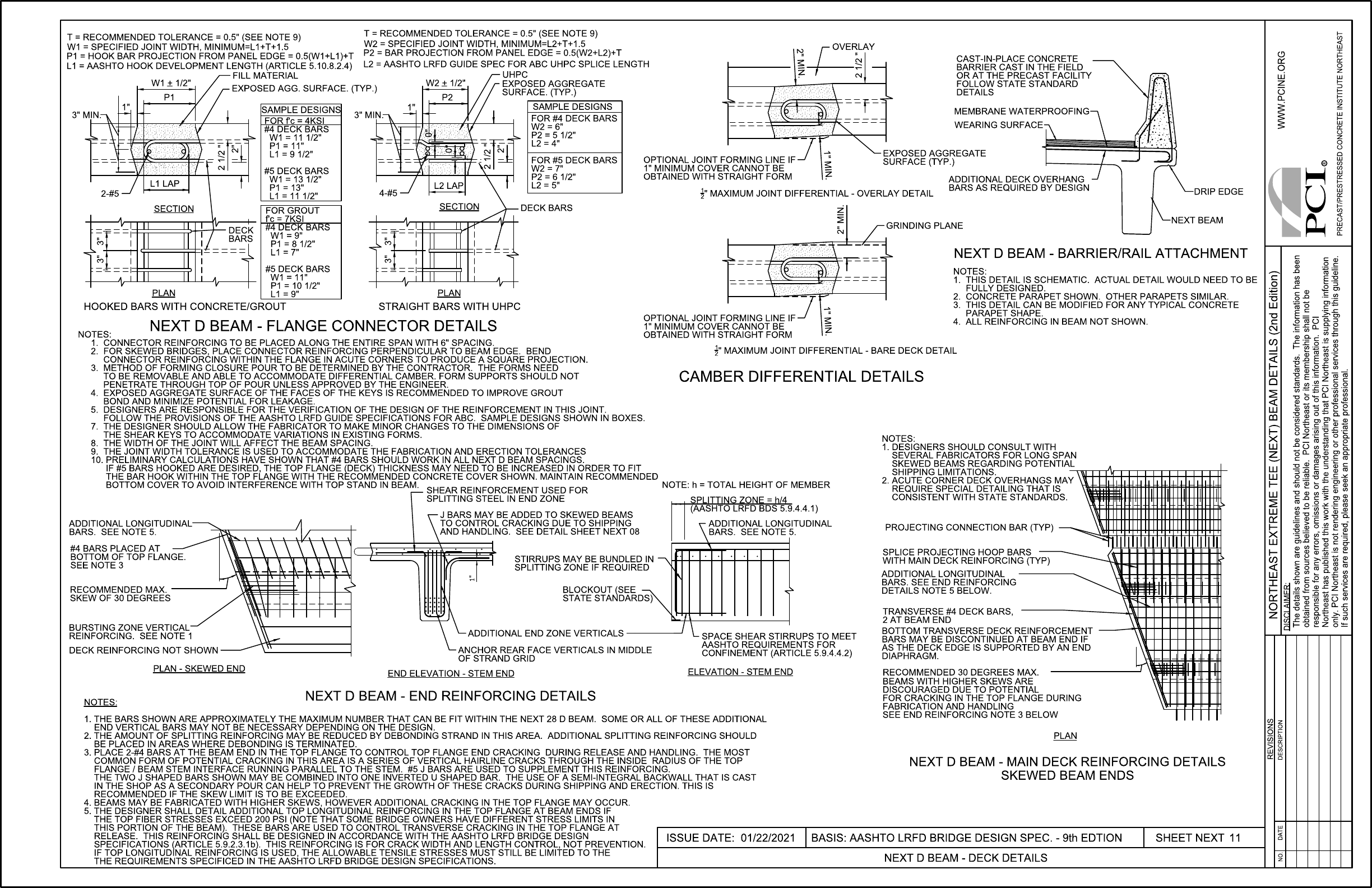

NEXT D BEAM - DECK DETAILS

NEXT 11

NEXT E BEAM - DECK DETAILS

NEXT 10

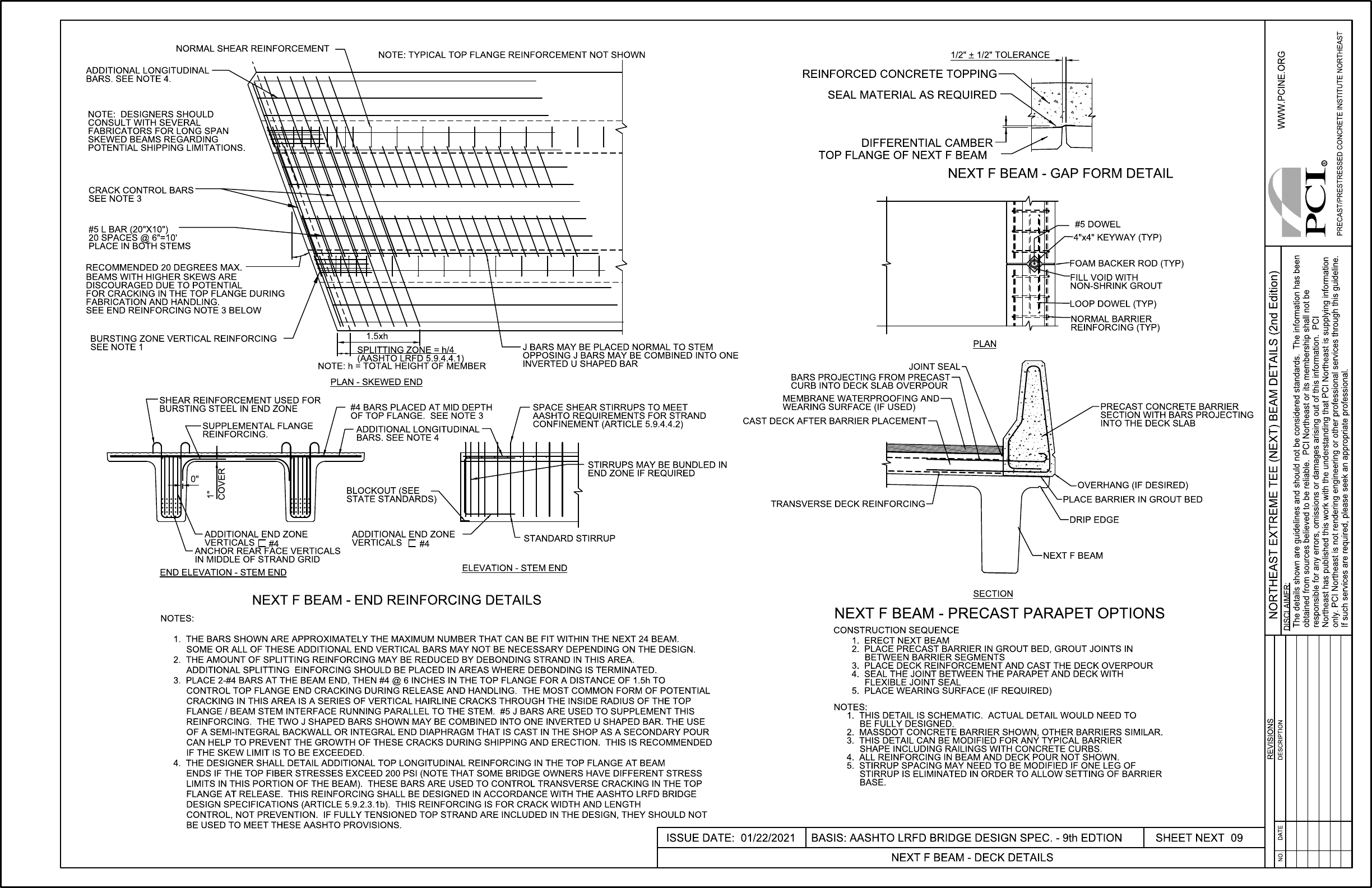

NEXT F BEAM - DECK DETAILS

NEXT 09

NEXT BEAM - TYPICAL BRIDGE SECTIONS

NEXT 08

NEXT BEAM - SECTION PROPERTIES

NEXT 07

NEXT BEAM - TYPICAL BEAM REINFORCING

NEXT 06

NEXT D - PROFILE ACCOMMODATION DETAILS

NEXT 05

NEXT E - PROFILE ACCOMMODATION DETAILS

NEXT 04

NEXT F - PROFILE ACCOMMODATION DETAILS

NEXT 03

BEAM USAGE

NEXT 02

GENERAL NOTES

NEXT 01

BEAMS AT THE BRIDGE SITE.

LIFTING METHODS SHOULD BE EMPLOYED FOR THE ERECTION OF THE

METHODS THAT MINIMIZE TWISTING OF THE BEAMS. THE SAME

SHIPPING AND HANDLING. THE FABRICATOR SHOULD DEVELOP

LONGITUDINAL TOP FLANGE CRACKING CAUSED BY TWISTING DURING

(PARTICULARLY NEXT F AND E BEAMS) ARE SENSITIVE TO

IS THE RESPONSIBILITY OF THE FABRICATOR. NEXT BEAMS

THE DESIGN OF SHIPPING AND HANDLING METHODS FOR NEXT BEAMS

5. INCLUDE THE FOLLOWING NOTE ON THE PLANS:

- FINAL

- 30 DAYS (OR ASSUMED DATE OF INSTALLATION)

- AT RELEASE

FOLLOWING INTERVALS:

4. CALCULATE CAMBERS AND NOTE THEM ON THE PLANS AT THE

- SPEED OF SET

- STRENGTH OF CONCRETE IN CLOSURE POURS

- FINAL STRENGTH

- RELEASE STRENGTH

3. SPECIFY THE REQUIRED CONCRETE STRENGTHS:

LOAD, SPECIAL DETAILS FOR INTEGRAL ABUTMENTS, ETC.

PRESTRESSING STRAND FOR BEAM ENDS FOR CONTINUITY OF LIVE

VARYING GEOMETRIC END TREATMENTS, EXTENSIONS OF

2. CREATE SPECIAL BEAM END DETAILS AS NEEDED, SUCH AS

- DECK OVERHANG AND BARRIER REINFORCING

- BEAM END REINFORCING

- SIZE AND SPACING OF SHEAR REINFORCING

DECKS ASSUMING THAT THE BEAM WEB IS A BEAM LINE.

SPECIFICATIONS. USE THE SAME METHODS AS CAST-IN-PLACE

CLOSURE POURS ACCORDING TO THE AASHTO LRFD BRIDGE DESIGN

- CHECK DECK REINFORCING IN THE TOP FLANGE AND THE

- NUMBER OF STRAIGHT STRAND AND LAYOUT

OWNER, INCLUDING:

DESIGN SPECIFICATIONS (9TH ED.) AND THE REQUIREMENTS OF THE

1. DESIGN THE BEAM ACCORDING TO THE AASHTO LRFD BRIDGE

IT IS THE DESIGNER'S RESPONSIBILITY TO:

THE ENTIRE NEXT D BEAM

- APPLY THE COMBINED DISTRIBUTION FACTOR FOR THE DESIGN OF

TOGETHER

- COMBINE (ADD) THE TWO DISTRIBUTION FACTORS FOR EACH STEM

SHALL APPLY

- THE APPLICATION OF THE LEVER RULE FOR EXTERIOR STEMS

THE TABLES IN ARTICLE 4.6.2.2.2.

- CALCULATE THE DISTRIBUTION FACTORS FOR EACH STEM USING

THE EQUATIONS

- USE THE AVERAGE STEM SPACING FOR THE BEAM SPACING TERM IN

- SEE ADJACENT DETAIL FOR CALCULATION OF e AND t

DECK)

COMPOSITE DECK (BOTTOM OF TOP FLANGE TO THE TOP OF THE

- ASSUME THAT THE FLANGE PORTION OF THE BEAM IS THE

(UP TO THE UNDERSIDE OF THE TOP FLANGE)

- ASSUME THAT THE STEM PORTION OF THE BEAM IS THE STRINGER

BEAM SECTION PROPERTIES USED FOR CALCULATION OF I AND A)

- TREAT EACH STEM AS AN INDIVIDUAL STRINGER (HALF OF TOTAL

THAT THE DECK IS SUFFICIENTLY CONNECTED TO ACT AS A UNIT

- USE AASHTO CROSS SECTION I (ARTICLE 4.6.2.2.1) ASSUMING

NEXT D BEAMS:

THE ENTIRE NEXT F BEAM

- APPLY THE COMBINED DISTRIBUTION FACTOR FOR THE DESIGN OF

TOGETHER

- COMBINE (ADD) THE TWO DISTRIBUTION FACTORS FOR EACH STEM

SHALL APPLY

- THE APPLICATION OF THE LEVER RULE FOR EXTERIOR STEMS

THE TABLES IN ARTICLE 4.6.2.2.2.

- CALCULATE THE DISTRIBUTION FACTORS FOR EACH STEM USING

THE EQUATIONS

- USE THE AVERAGE STEM SPACING FOR THE BEAM SPACING TERM IN

- SEE ADJACENT DETAIL FOR CALCULATION OF e AND t

BEAM SECTION PROPERTIES USED FOR CALCULATION OF I AND A)

- TREAT EACH STEM AS AN INDIVIDUAL STRINGER (HALF OF TOTAL

- USE AASHTO CROSS SECTION K (ARTICLE 4.6.2.2.1)

NEXT F AND E BEAMS:

- PROVIDES ADDITIONAL DECK PROTECTION

- ACCOUNTS FOR TOP FLANGE DIFFERENTIAL

- ELIMINATES THE NEED FOR DECK GRINDING

RECOMMENDED FOR THE FOLLOWING REASONS:

DECK OVERLAYS COMBINED WITH WATERPROOFING MEMBRANES ARE

THICKNESS FOR BEAM WEIGHT.

IN THE SECTION PROPERTIES, HOWEVER INCLUDE FULL DECK

" OF TOP FLANGE

2

1

ACCOUNT FOR THIS IN DESIGN, ASSUME LOSS OF

ROADWAY SURFACES AT LONGITUDINAL JOINTS MAY BE USED. TO

" CONCRETE GRINDING ALLOWANCE FOR CORRECTING UNEVEN

2

1

A

AASHTO M 203 GRADE 270

PRESTRESSING STRAND: LOW RELAXATION STRAND, 0.6" DIAMETER,

STANDARDS)

REINFORCING STEEL: fy = 60,000 PSI (COATING AS PER AGENCY

(1ST EDITION).

GUIDE SPECIFICATIONS FOR ACCELERATED BRIDGE CONSTRUCTION

DESIG SPECIFICATIONS (9TH EDITION) AND THE AASHTO LRFD

THE BASIS FOR THESE GUIDE DETAILS IS THE AASHTO LRFD BRIDGE

12

VARIES

0.375

13" 13"

5'-0"

6'-0"6'-0"

2

'

-

8

"

" CHAMFER (TYP)

4

3

R=4" (TYP)

NEXT BEAM DESIGN ENVELOPE

15" 15"

CENTERLINE OF BEAM

STEEL. SEE DETAIL SHEET NEXT 06.

THE OVERALL SHIPPING WIDTH OF THE BEAM WITH PROJECTING REINFORCING

6. LIMITATIONS ON WIDTH FOR NEXT D BASED ON WEIGHT OF THE BEAM AND

NEXT 06.

OF 12 FEET (INCLUDING PROJECTING REINFORCING STEEL). SEE DETAIL SHEET

5. LIMITATIONS ON WIDTH FOR NEXT E BASED ON MAXIMUM SHIPPING WIDTH

OF THE BOTTOM OF THE STEM.

STEMS, RESULTING IN MINOR VARIATIONS IN THE WIDTH OF THE BOTTOM

4. DEPTH VARIATIONS ACCOMMODATED BY INSERTS IN THE BOTTOM OF THE

3. ANY REASONABLE THICKNESS OF TOP FLANGE CAN BE PROVIDED.

DESIRED).

REQUIRE SPECIAL FORMING IN THE SHOP (CONTACT FABRICATORS IF THIS IS

FLANGE CAN BE EXCEEDED; HOWEVER, IT IS NOT RECOMMENDED AS IT WILL

ADJUSTABLE SIDE FORMS ON THE TOP FLANGE FORM. THE WIDTH OF THE TOP

2. THE VARIABLE WIDTH OF NEXT BEAM IS ACCOMMODATED WITH

DENOTES THE NEXT BEAM FORM THAT CANNOT BE ALTERED.

USED TO DESIGN A NEXT BEAM. THE LOWER PORTION OF THE ENVELOPE

1. THE PURPOSE OF THIS DETAIL IS TO DEFINE THE ENVELOPE THAT CAN BE

NOTES:

IN eg CALCULATION

NEGLECT THIS PORTION OF DECK

t

s

t

e

gg

e

g

e

t

s

s

NEXT F

NEXT E

NEXT D

TREAT TOPPING AS THE "DECK"

TREAT STEM AND TOP FLANGE AS THE "BEAM"

TREAT TOPPING AS THE "DECK"

TREAT STEM AND TOP FLANGE AS THE "BEAM"

TREAT TOP FLANGE AS THE "DECK"

TREAT STEM AS THE "BEAM"

P

C

I

If

s

u

c

h

s

e

r

v

i

ce

s

a

r

e

r

e

qu

i

r

e

d

,

p

l

ea

s

e

s

ee

k

a

n

a

pp

r

op

r

i

a

t

e

p

r

o

f

e

ss

i

on

a

l

.

on

l

y

.

P

C

I

N

o

r

t

h

ea

s

t

i

s

no

t

r

e

nd

e

r

i

ng

e

ng

i

n

ee

r

i

ng

o

r

o

t

h

e

r

p

r

o

f

e

ss

i

on

a

l

s

e

r

v

i

ce

s

t

h

r

ough

t

h

i

s

gu

i

d

e

li

n

e

.

N

o

r

t

h

ea

s

t

h

a

s

pub

li

s

h

e

d

t

h

i

s

w

o

r

k

w

it

h

t

h

e

und

e

r

s

t

a

nd

i

ng

t

h

a

t

P

C

I

N

o

r

t

h

ea

s

t

i

s

s

upp

l

y

i

ng

i

n

f

o

r

m

a

ti

on

r

e

s

pon

s

i

b

l

e

f

o

r

a

ny

e

rr

o

r

s

,

o

m

i

ss

i

on

s

o

r

d

a

m

a

g

e

s

a

r

i

s

i

ng

ou

t

o

f

t

h

i

s

i

n

f

o

r

m

a

ti

on

.

P

C

I

ob

t

a

i

n

e

d

fr

o

m

s

ou

r

ce

s

b

e

li

e

v

e

d

t

o

b

e

r

e

li

a

b

l

e

.

P

C

I

N

o

r

t

h

ea

s

t

o

r

it

s

m

e

m

b

e

r

s

h

i

p

s

h

a

ll

no

t

b

e

T

h

e

d

e

t

a

il

s

s

ho

w

n

a

r

e

gu

i

d

e

li

n

e

s

a

nd

s

hou

l

d

no

t

b

e

c

on

s

i

d

e

r

e

d

s

t

a

nd

a

r

d

s

.

T

h

e

i

n

f

o

r

m

a

ti

on

h

a

s

b

ee

n

D

I

S

C

L

A

I

M

E

R

:

NO

.

DA

TE

D

E

S

CR

I

P

T

I

ON

R

E

V

I

S

I

ON

S

P

R

E

C

A

S

T

/

P

R

E

S

T

R

E

SS

E

D

C

ON

CR

ETE

I

N

S

T

I

T

U

TE

NO

R

T

H

E

A

S

T

W W W

.

P

C

I

N

E

.

O

R

G

R

SHEET NEXT

NO

R

T

H

E

A

S

T

E

X

T

R

E

M

E

TEE

(

N

E

X

T

)

B

E

A

M

D

ET

A

I

L

S

(

2nd

E

d

iti

on

)

ISSUE DATE: 01/22/2021

BASIS: AASHTO LRFD BRIDGE DESIGN SPEC. - 9th EDTION

BEAM USAGE GUIDELINES

BEAM USAGE

02

NEXT D BEAMS

NEXT F BEAMS

NEXT E BEAMS

REINFORCED CIP CONCRETE DECK

8" MINIMUM

WEARING SURFACE

4" TOP FLANGE

REINFORCED CIP CONCRETE DECK

" MINIMUM

2

1

4

WEARING SURFACE

TOP FLANGE

4" INTEGRAL PARTIAL DECK/

INTEGRAL DECK/TOP FLANGE

8" MINIMUM

WEARING SURFACE

P

C

I

If

s

u

c

h

s

e

r

v

i

ce

s

a

r

e

r

e

qu

i

r

e

d

,

p

l

ea

s

e

s

ee

k

a

n

a

pp

r

op

r

i

a

t

e

p

r

o

f

e

ss

i

on

a

l

.

on

l

y

.

P

C

I

N

o

r

t

h

ea

s

t

i

s

no

t

r

e

nd

e

r

i

ng

e

ng

i

n

ee

r

i

ng

o

r

o

t

h

e

r

p

r

o

f

e

ss

i

on

a

l

s

e

r

v

i

ce

s

t

h

r

ough

t

h

i

s

gu

i

d

e

li

n

e

.

N

o

r

t

h

ea

s

t

h

a

s

pub

li

s

h

e

d

t

h

i

s

w

o

r

k

w

it

h

t

h

e

und

e

r

s

t

a

nd

i

ng

t

h

a

t

P

C

I

N

o

r

t

h

ea

s

t

i

s

s

upp

l

y

i

ng

i

n

f

o

r

m

a

ti

on

r

e

s

pon

s

i

b

l

e

f

o

r

a

ny

e

rr

o

r

s

,

o

m

i

ss

i

on

s

o

r

d

a

m

a

g

e

s

a

r

i

s

i

ng

ou

t

o

f

t

h

i

s

i

n

f

o

r

m

a

ti

on

.

P

C

I

ob

t

a

i

n

e

d

fr

o

m

s

ou

r

ce

s

b

e

li

e

v

e

d

t

o

b

e

r

e

li

a

b

l

e

.

P

C

I

N

o

r

t

h

ea

s

t

o

r

it

s

m

e

m

b

e

r

s

h

i

p

s

h

a

ll

no

t

b

e

T

h

e

d

e

t

a

il

s

s

ho

w

n

a

r

e

gu

i

d

e

li

n

e

s

a

nd

s

hou

l

d

no

t

b

e

c

on

s

i

d

e

r

e

d

s

t

a

nd

a

r

d

s

.

T

h

e

i

n

f

o

r

m

a

ti

on

h

a

s

b

ee

n

D

I

S

C

L

A

I

M

E

R

:

NO

.

DA

TE

D

E

S

CR

I

P

T

I

ON

R

E

V

I

S

I

ON

S

P

R

E

C

A

S

T

/

P

R

E

S

T

R

E

SS

E

D

C

ON

CR

ETE

I

N

S

T

I

T

U

TE

NO

R

T

H

E

A

S

T

W W W

.

P

C

I

N

E

.

O

R

G

R

SHEET NEXT

NO

R

T

H

E

A

S

T

E

X

T

R

E

M

E

TEE

(

N

E

X

T

)

B

E

A

M

D

ET

A

I

L

S

(

2nd

E

d

iti

on

)

ISSUE DATE: 01/22/2021

BASIS: AASHTO LRFD BRIDGE DESIGN SPEC. - 9th EDTION

NOTES

GUIDE.

CAMBER, SEE PCI NORTHEAST PROFILE AND CAMBER MANAGEMENT

6. FOR MORE INFORMATION ON ACCOMMODATION OF PROFILES AND

SHOULD BE BASED ON THE ESTIMATED CAMBER AT ERECTION.

5. THE ESTIMATED CAMBER USED FOR THE VARIABLES NOTED ABOVE

THICKNESS TOPPING IN THE DESIGN OF THE BEAM.

4. THE ENGINEER SHOULD ACCOUNT FOR THE ESTIMATED VARIABLE

TO THE HEIGHT OF THE CURB OR BARRIER.

ADJUST THE TOPPING THICKNESS AS REQUIRED. THE SAME APPLIES

REQUIRING SURVEY OF THE BEAMS AFTER ERECTION, AND THEN

THE ESTIMATED CAMBER. THE PLANS SHOULD INCLUDE NOTES

THICKNESS OF THE TOPPING OR OVERLAY ON THE PLANS BASED ON

3. THE ENGINEER SHOULD DETAIL THE ANTICIPATED VARIABLE

PROFILE DETAILS.

CURVE ORDINATE, THE DETAILS WILL BE SIMILAR TO THE TANGENT

2. CREST VERTICAL CURVES: IF THE CAMBER IS LESS THAN THE

PARAPET WILL STILL VARY.

OF THE OVERLAY. NOTE THAT THE HEIGHT OF THE CURB OR

CONCRETE TOPPING. ANOTHER OPTION IS TO VERY THE THICKNESS

1. THE DETAILS SHOWN DEPICT VARYING THE THICKNESS OF THE

NEXT F - PROFILE ACCOMODATION DETAILS

03

P

C

I

If

s

u

c

h

s

e

r

v

i

ce

s

a

r

e

r

e

qu

i

r

e

d

,

p

l

ea

s

e

s

ee

k

a

n

a

pp

r

op

r

i

a

t

e

p

r

o

f

e

ss

i

on

a

l

.

on

l

y

.

P

C

I

N

o

r

t

h

ea

s

t

i

s

no

t

r

e

nd

e

r

i

ng

e

ng

i

n

ee

r

i

ng

o

r

o

t

h

e

r

p

r

o

f

e

ss

i

on

a

l

s

e

r

v

i

ce

s

t

h

r

ough

t

h

i

s

gu

i

d

e

li

n

e

.

N

o

r

t

h

ea

s

t

h

a

s

pub

li

s

h

e

d

t

h

i

s

w

o

r

k

w

it

h

t

h

e

und

e

r

s

t

a

nd

i

ng

t

h

a

t

P

C

I

N

o

r

t

h

ea

s

t

i

s

s

upp

l

y

i

ng

i

n

f

o

r

m

a

ti

on

r

e

s

pon

s

i

b

l

e

f

o

r

a

ny

e

rr

o

r

s

,

o

m

i

ss

i

on

s

o

r

d

a

m

a

g

e

s

a

r

i

s

i

ng

ou

t

o

f

t

h

i

s

i

n

f

o

r

m

a

ti

on

.

P

C

I

ob

t

a

i

n

e

d

fr

o

m

s

ou

r

ce

s

b

e

li

e

v

e

d

t

o

b

e

r

e

li

a

b

l

e

.

P

C

I

N

o

r

t

h

ea

s

t

o

r

it

s

m

e

m

b

e

r

s

h

i

p

s

h

a

ll

no

t

b

e

T

h

e

d

e

t

a

il

s

s

ho

w

n

a

r

e

gu

i

d

e

li

n

e

s

a

nd

s

hou

l

d

no

t

b

e

c

on

s

i

d

e

r

e

d

s

t

a

nd

a

r

d

s

.

T

h

e

i

n

f

o

r

m

a

ti

on

h

a

s

b

ee

n

D

I

S

C

L

A

I

M

E

R

:

NO

.

DA

TE

D

E

S

CR

I

P

T

I

ON

R

E

V

I

S

I

ON

S

P

R

E

C

A

S

T

/

P

R

E

S

T

R

E

SS

E

D

C

ON

CR

ETE

I

N

S

T

I

T

U

TE

NO

R

T

H

E

A

S

T

W W W

.

P

C

I

N

E

.

O

R

G

R

SHEET NEXT

NO

R

T

H

E

A

S

T

E

X

T

R

E

M

E

TEE

(

N

E

X

T

)

B

E

A

M

D

ET

A

I

L

S

(

2nd

E

d

iti

on

)

ISSUE DATE: 01/22/2021

BASIS: AASHTO LRFD BRIDGE DESIGN SPEC. - 9th EDTION

NEXT F BEAMS

NEXT F BEAMS - TANGENT PROFILE

NEXT F BEAMS - CREST VERTICAL CURVE PROFILE

NEXT F BEAMS - SAG VERTICAL CURVE PROFILE

OPTION 2: VARY OVERLAY THICKESS

OPTION 1: VARY TOPPING THICKESS

FOR TYPICAL BEAM BRIDGES

MINIMUM THICKNESS AS PER STATE STANDARDS

REINFORCED CIP CONCRETE DECK

4" TOP FLANGE

WEARING SURFACE

CAUSED BY BEAM CAMBER

THICKER TOPPING THICKNESS AT ENDS

MINIMUM TOPPING THICKNESS AT MID-SPAN

MINIMUM TOPPING THICKNESS IF CAMBER IS LESS THAN ORDINATE

CURVE ORDINATE IS LARGER THAN CAMBER

THICKER TOPPING THICKNESS AT MID-SPAN IF VERTICAL

THICKER TOPPING IF CAMBER IS LESS THAN ORDINATE

CURVE ORDINATE IS LARGER THAN CAMBER

MINIMUM TOPPING THICKNESS AT ENDS IF VERTICAL

CONSTANT HEIGHT CURB/BARRIER

CONSTANT THICKNESS OVERLAY

THICKNESS VARIES

PLUS BEAM CAMBER

CAUSED BY VERTICAL CURVE ORDINATE

THICKER TOPPING THICKNESS AT ENDS

MINIMUM TOPPING THICKNESS AT MID-SPAN

TOPPING

CONSTANT THICKNESS

OVERLAY THICKNESS VARIES

CURB/BARRIER HEIGHT VARIES

NOTES

04

NEXT E - PROFILE ACCOMMODATION DETAILS

(PCINE-18-GCPMAB).

CAMBER AND PROFILE MANAGEMENT IN ADJACENT BEAMS

CAMBER, SEE PCI NORTHEAST DOCUMENT ENTITLED GUIDELINES FOR

6. FOR MORE INFORMATION ON ACCOMMODATION OF PROFILES AND

SHOULD BE BASED ON THE ESTIMATED CAMBER AT ERECTION.

5. THE ESTIMATED CAMBER USED FOR THE VARIABLES NOTED ABOVE

THICKNESS TOPPING IN THE DESIGN OF THE BEAM.

4. THE ENGINEER SHOULD ACCOUNT FOR THE ESTIMATED VARIABLE

APPLIES TO THE HEIGHT OF THE CURB OR BARRIER.

ADJUSTMENT OF THE TOPPING THICKNESS AS REQUIRED. THE SAME

REQUIRING SURVEY OF THE BEAMS AFTER ERECTION, AND THEN

THE ESTIMATED CAMBER. THE PLANS SHOULD INCLUDE NOTES

THICKNESS OF THE TOPPING OR OVERLAY ON THE PLANS BASED ON

3. THE ENGINEER SHOULD DETAIL THE ANTICIPATED VARIABLE

PROFILE DETAILS.

CURVE ORDINATE, THE DETAILS WILL BE SIMILAR TO THE TANGENT

2. CREST VERTICAL CURVES: IF THE CAMBER IS LESS THAN THE

PARAPET WILL STILL VARY.

OF THE OVERLAY. NOTE THAT THE HEIGHT OF THE CURB OR

CONCRETE TOPPING. ANOTHER OPTION IS TO VERY THE THICKNESS

1. THE DETAILS SHOWN DEPICT VARYING THE THICKNESS OF THE

P

C

I

If

s

u

c

h

s

e

r

v

i

ce

s

a

r

e

r

e

qu

i

r

e

d

,

p

l

ea

s

e

s

ee

k

a

n

a

pp

r

op

r

i

a

t

e

p

r

o

f

e

ss

i

on

a

l

.

on

l

y

.

P

C

I

N

o

r

t

h

ea

s

t

i

s

no

t

r

e

nd

e

r

i

ng

e

ng

i

n

ee

r

i

ng

o

r

o

t

h

e

r

p

r

o

f

e

ss

i

on

a

l

s

e

r

v

i

ce

s

t

h

r

ough

t

h

i

s

gu

i

d

e

li

n

e

.

N

o

r

t

h

ea

s

t

h

a

s

pub

li

s

h

e

d

t

h

i

s

w

o

r

k

w

it

h

t

h

e

und

e

r

s

t

a

nd

i

ng

t

h

a

t

P

C

I

N

o

r

t

h

ea

s

t

i

s

s

upp

l

y

i

ng

i

n

f

o

r

m

a

ti

on

r

e

s

pon

s

i

b

l

e

f

o

r

a

ny

e

rr

o

r

s

,

o

m

i

ss

i

on

s

o

r

d

a

m

a

g

e

s

a

r

i

s

i

ng

ou

t

o

f

t

h

i

s

i

n

f

o

r

m

a

ti

on

.

P

C

I

ob

t

a

i

n

e

d

fr

o

m

s

ou

r

ce

s

b

e

li

e

v

e

d

t

o

b

e

r

e

li

a

b

l

e

.

P

C

I

N

o

r

t

h

ea

s

t

o

r

it

s

m

e

m

b

e

r

s

h

i

p

s

h

a

ll

no

t

b

e

T

h

e

d

e

t

a

il

s

s

ho

w

n

a

r

e

gu

i

d

e

li

n

e

s

a

nd

s

hou

l

d

no

t

b

e

c

on

s

i

d

e

r

e

d

s

t

a

nd

a

r

d

s

.

T

h

e

i

n

f

o

r

m

a

ti

on

h

a

s

b

ee

n

D

I

S

C

L

A

I

M

E

R

:

NO

.

DA

TE

D

E

S

CR

I

P

T

I

ON

R

E

V

I

S

I

ON

S

P

R

E

C

A

S

T

/

P

R

E

S

T

R

E

SS

E

D

C

ON

CR

ETE

I

N

S

T

I

T

U

TE

NO

R

T

H

E

A

S

T

W W W

.

P

C

I

N

E

.

O

R

G

R

SHEET NEXT

NO

R

T

H

E

A

S

T

E

X

T

R

E

M

E

TEE

(

N

E

X

T

)

B

E

A

M

D

ET

A

I

L

S

(

2nd

E

d

iti

on

)

ISSUE DATE: 01/22/2021

BASIS: AASHTO LRFD BRIDGE DESIGN SPEC. - 9th EDTION

NEXT E BEAMS

NEXT E BEAMS - TANGENT PROFILE

NEXT E BEAMS - CREST VERTICAL CURVE PROFILE

NEXT E BEAMS - SAG VERTICAL CURVE PROFILE

OPTION 2: VARY OVERLAY THICKESS

OPTION 1: VARY TOPPING THICKESS

" MINIMUM

2

1

4

REINFORCED CIP CONCRETE DECK

WEARING SURFACE

TOP FLANGE

4" INTEGRAL PARTIAL DECK/

MINIMUM TOPPING THICKNESS AT MID-SPAN

CAUSED BY BEAM CAMBER

THICKER TOPPING THICKNESS AT ENDS

CONSTANT HEIGHT CURB/BARRIER

CONSTANT THICKNESS OVERLAY

THICKNESS VARIES

CURB/BARRIER HEIGHT VARIES

OVERLAY THICKNESS VARIES

PLUS BEAM CAMBER

CAUSED BY VERTICAL CURVE ORDINATE

THICKER TOPPING THICKNESS AT ENDS

MINIMUM TOPPING THICKNESS AT MID-SPAN

MINIMUM TOPPING THICKNESS IF CAMBER IS LESS THAN ORDINATE

CURVE ORDINATE IS LARGER THAN CAMBER

THICKER TOPPING THICKNESS AT MID-SPAN IF VERTICAL

THICKER TOPPING IF CAMBER IS LESS THAN ORDINATE

CURVE ORDINATE IS LARGER THAN CAMBER

MINIMUM TOPPING THICKNESS AT ENDS IF VERTICAL

CONSTANT THICKNESS TOPPING

NOTES

05

NEXT D - PROFILE ACCOMODATION DETAILS

(PCINE-18-GCPMAB).

CAMBER AND PROFILE MANAGEMENT IN ADJACENT BEAMS

CAMBER, SEE PCI NORTHEAST DOCUMENT ENTITLED GUIDELINES FOR

6. FOR MORE INFORMATION ON ACCOMMODATION OF PROFILES AND

SHOULD BE BASED ON THE ESTIMATED CAMBER AT ERECTION.

5. THE ESTIMATED CAMBER USED FOR THE VARIABLE NOTED ABOVE

BEAM.

THICKNESS TOP FLANGE AND/OR TOPPING IN THE DESIGN OF THE

4. THE ENGINEER SHOULD ACCOUNT FOR THE ESTIMATED VARIABLE

SAME APPLIES TO THE HEIGHT OF THE CURB OR BARRIER.

ADJUSTMENT OF THE OVERLAY THICKNESS MAY BE REQUIRED. THE

REQUIRING SURVEY OF THE BEAMS AFTER ERECTION, AND THEN

ON THE ESTIMATED CAMBER. THE PLANS SHOULD INCLUDE NOTES

THICKNESS OF THE TOP FLANGE OR OVERLAY ON THE PLANS BASED

3. THE ENGINEER SHOULD DETAIL THE ANTICIPATED VARIABLE

PROFILE DETAILS.

CURVE ORDINATE, THE DETAILS WILL BE SIMILAR TO THE TANGENT

2. CREST VERTICAL CURVES: IF THE CAMBER IS LESS THAN THE

STILL VARY.

OVERLAY. NOTE THAT THE HEIGHT OF THE CURB OR PARAPET WILL

TOP FLANGE. ANOTHER OPTION IS TO VERY THE THICKNESS OF THE

1. THE DETAILS SHOWN DEPICT VARYING THE THICKNESS OF THE

P

C

I

If

s

u

c

h

s

e

r

v

i

ce

s

a

r

e

r

e

qu

i

r

e

d

,

p

l

ea

s

e

s

ee

k

a

n

a

pp

r

op

r

i

a

t

e

p

r

o

f

e

ss

i

on

a

l

.

on

l

y

.

P

C

I

N

o

r

t

h

ea

s

t

i

s

no

t

r

e

nd

e

r

i

ng

e

ng

i

n

ee

r

i

ng

o

r

o

t

h

e

r

p

r

o

f

e

ss

i

on

a

l

s

e

r

v

i

ce

s

t

h

r

ough

t

h

i

s

gu

i

d

e

li

n

e

.

N

o

r

t

h

ea

s

t

h

a

s

pub

li

s

h

e

d

t

h

i

s

w

o

r

k

w

it

h

t

h

e

und

e

r

s

t

a

nd

i

ng

t

h

a

t

P

C

I

N

o

r

t

h

ea

s

t

i

s

s

upp

l

y

i

ng

i

n

f

o

r

m

a

ti

on

r

e

s

pon

s

i

b

l

e

f

o

r

a

ny

e

rr

o

r

s

,

o

m

i

ss

i

on

s

o

r

d

a

m

a

g

e

s

a

r

i

s

i

ng

ou

t

o

f

t

h

i

s

i

n

f

o

r

m

a

ti

on

.

P

C

I

ob

t

a

i

n

e

d

fr

o

m

s

ou

r

ce

s

b

e

li

e

v

e

d

t

o

b

e

r

e

li

a

b

l

e

.

P

C

I

N

o

r

t

h

ea

s

t

o

r

it

s

m

e

m

b

e

r

s

h

i

p

s

h

a

ll

no

t

b

e

T

h

e

d

e

t

a

il

s

s

ho

w

n

a

r

e

gu

i

d

e

li

n

e

s

a

nd

s

hou

l

d

no

t

b

e

c

on

s

i

d

e

r

e

d

s

t

a

nd

a

r

d

s

.

T

h

e

i

n

f

o

r

m

a

ti

on

h

a

s

b

ee

n

D

I

S

C

L

A

I

M

E

R

:

NO

.

DA

TE

D

E

S

CR

I

P

T

I

ON

R

E

V

I

S

I

ON

S

P

R

E

C

A

S

T

/

P

R

E

S

T

R

E

SS

E

D

C

ON

CR

ETE

I

N

S

T

I

T

U

TE

NO

R

T

H

E

A

S

T

W W W

.

P

C

I

N

E

.

O

R

G

R

SHEET NEXT

NO

R

T

H

E

A

S

T

E

X

T

R

E

M

E

TEE

(

N

E

X

T

)

B

E

A

M

D

ET

A

I

L

S

(

2nd

E

d

iti

on

)

ISSUE DATE: 01/22/2021

BASIS: AASHTO LRFD BRIDGE DESIGN SPEC. - 9th EDTION

NEXT D BEAMS

NEXT D BEAMS - TANGENT PROFILE

NEXT D BEAMS - CREST VERTICAL CURVE PROFILE

NEXT D BEAMS - SAG VERTICAL CURVE PROFILE

OPTION 1: VARY FLANGE THICKESS

OPTION 2: VARY OVERLAY THICKESS

INTEGRAL DECK/TOP FLANGE

8" MINIMUM

WEARING SURFACE

CAUSED BY BEAM CAMBER

THICKER TOP FLANGE THICKNESS AT ENDS

MINIMUM TOP FLANGE THICKNESS AT MID-SPAN

THICKER TOPPING IF CAMBER IS LESS THAN ORDINATE

CURVE ORDINATE IS LARGER THAN CAMBER

MINIMUM TOP FLANGE THICKNESS AT ENDS IF VERTICAL

MINIMUM TOP FLANGE THICKNESS IF CAMBER IS LESS THAN ORDINATE

CURVE ORDINATE IS LARGER THAN CAMBER

THICKER TOP FLANGE THICKNESS AT MID-SPAN IF VERTICAL

CONSTANT HEIGHT CURB/BARRIER

CONSTANT OVERLAY THICKNESS

THICKNESS VARIES

TOP FLANGE

BARRIER/CURB HEIGHT VARIES

OVERLAY THICKNESS VARIES

CONSTANT FLANGE THICKNESS

MINIMUM TOP FLANGE THICKNESS AT MID-SPAN

PLUS BEAM CAMBER

CAUSED BY VERTICAL CURVE ORDINATE

THICKER TOP FLANGE THICKNESS AT ENDS

NORMAL DECK REINFORCEMENT

#4 @ 6"

#4 @ 6"

2-#4

VA

R

I

E

S

VA

R

I

E

S

"

2

1

OV

E

R

10

FLANGES UNDER 10 1/2"

FLANGES OVER 10 1/2"

"

2

1

2

"

2

1

8

"

T

O

10

FLANGE ADJUSTMENT FOR PROFILE

1

NEXT E NOTES

NEXT F NOTES

NEXT D NOTES

DESIGN NOTES

STRAND LAYOUT NOTES

06

NEXT BEAM - TYPICAL BEAM REINFORCING

4. SEE DETAIL SHEET NEXT 15 FOR UTILITIES SUPPORT DETAILS.

STEM.

3. SHEAR REINFORCING SHOULD BE KEPT TO #4 BARS IN ORDER TO MAXIMIZE THE COVER ON THE SIDE OF THE

DECK ASSUMING THAT THE STEMS ARE INDIVIDUAL BEAMS.

2. THE DESIGN OF THE DECK REINFORCING SHOULD BE BASED ON A CONVENTIONAL CAST-IN-PLACE CONCRETE

VERIFY THIS REINFORCING FOR EACH DESIGN BASED ON THE ACTUAL DECK THICKNESS.

INCH THICK DECK. DESIGNERS SHOULD

2

1

SHOWN IS BASED ON A PRELIMINARY DESIGN OF A NEXT BEAM WITH AN 8

CAST-IN-PLACE CONCRETE TOPPING SHOULD BE DESIGNED TO COMPLETE THE STRUCTURAL DECK. THE REINFORCING

1. THE TOP FLANGE IS INTENDED TO ACT AS THE BOTTOM PORTION OF THE DECK. A REINFORCED

FACILITATE THE INSTALLATION OF THE STIRRUPS.

4. MINOR ADJUSTMENT OF THE SPACING OF THE TOP LONGITUDINAL REINFORCEMENT IS ALLOWABLE TO

3. SEE DETAIL SHEET NEXT 15 FOR UTILITY SUPPORT DETAILS.

STEM.

2. SHEAR REINFORCING SHOULD BE KEPT TO #4 BARS IN ORDER TO MAXIMIZE THE COVER ON THE SIDE OF THE

1. THE TOP FLANGE IS INTENDED TO ACT AS A STRUCTURAL DECK.

STRESS IN THE BEAM.

SHOULD NOT BE USED TO MEET THESE AASHTO PROVISIONS, SINCE THEY ARE ALREADY BEING USED TO CONTROL

PREVENTION. IT IS RECOMMENDED THAT IF FULLY TENSIONED TOP STRAND ARE INCLUDED IN THE DESIGN, THEY

LRFD BRIDGE DESIGN SPECIFICATIONS. THIS REINFORCING IS FOR CRACK WIDTH AND LENGTH CONTROL, NOT

IN THE TOP FLANGE AT RELEASE. THIS REINFORCING SHALL BE DESIGNED IN ACCORDANCE WITH THE AASHTO

ENDS IF THE TOP FIBER STRESSES EXCEED 200 PSI. THESE BARS ARE USED TO CONTROL TRANSVERSE CRACKING

5. THE DESIGNER SHALL DETAIL ADDITIONAL TOP LONGITUDINAL REINFORCING IN THE TOP FLANGE AT BEAM

4. ADDITIONAL REINFORCEMENT MAY BE REQUIRED FOR DECK OVERHANGS AND BARRIERS.

THE CRACK CONTROL PROVISIONS OF AASHTO ARTICLE 5.6.7 SHOULD ALSO BE CHECKED FOR THESE BARS.

DECK DESIGN. THE NESTED HOOKED BARS CAN BE CONSIDERED A LAP SPLICE WITH THE BARS FULLY DEVELOPED.

THE POSITIVE BENDING MOMENT AT THE CENTER OF THE JOINT AS DETERMINED BY THE AASHTO STRIP METHOD OF

3. THE REINFORCING BARS EXTENSIONS SHOWN IN THE NEXT E AND D BEAMS SHOULD BE DESIGNED TO RESIST

REINFORCING IN THE NEXT E AND D BEAMS.

2. THE STRIP METHOD SPECIFIED IN AASHTO LRFD ARTICLE 4.6.2.1 IS RECOMMENDED FOR THE DESIGN OF THE

FOR EACH DESIGN BASED ON THE AASHTO LRFD BRIDGE DESIGN SPECIFICATIONS OR STATE STANDARDS.

1. THE REINFORCING SHOWN IS PRELIMINARY AND NOT GUARANTEED. DESIGNERS MUST VERIFY THE REINFORCING

TOP FLANGE REINFORCING.

9. ADDITIONAL STRAND TENSIONED TO A NOMINAL VALUE MAY BE ADDED TO THE TOP FLANGE TO SUPPORT THE

CONFORMING TO AASHTO M203. THE ULTIMATE STRENGTH OF THE STRANDS SHALL BE 270 KSI.

8. ALL PRESTRESSING STRAND SHALL BE 0.6" DIAMETER, UNCOATED SEVEN WIRE, LOW RELAXATION STRANDS

REINFORCEMENT BAR BENDS.

7. THE TWO BOTTOM CORNER STRAND IN EACH STEM ARE OMITTED TO PROVIDE ROOM FOR THE SHEAR

STRAND). THIS IS BASED ON THE CAPACITY OF TYPICAL CASTING BEDS.

6. THE PATTERN SHOWN DEPICTS THE MAXIMUM NUMBER OF STRANDS ALLOWED (50 STRAND INCLUDING THE TOP

AS REQUIRED BY DESIGN.

DESIGNS THAT REQUIRE PRESTRESS AT A HIGHER ELEVATION. THE NUMBER AND LOCATION OF STRANDS SHALL BE

5. STRANDS SHALL BE PLACED WITHIN THE 2"x2" GRID. THE PATTERN MAY BE RAISED IN 2" INCREMENTS FOR

PREFERRED, BUT NOT MANDATORY.

4. DEBONDING SHOULD BE SYMETRICAL ABOUT THE CETNERLINE OF THE BEAM. SYMETRY ABOUT THE STEM IS

DEBONDING SHALL ALSO BE FOLLOWED.

3. AASHTO PROVISIONS FOR DEBONDED STRANDS (ARTICLE 5.9.4.3.3) REGARDING LONGITUDINAL LIMITS OF

THE PROVISIONS FOR "DEBONDED STRANDS" IN THE AASHTO LRFD BRIDGE DESIGN SPECIFICATIONS ARE FOLLOWED.

NUMBER OF STRANDS. SIMILAR DEBONDING CAN BE USED FOR SECTIONS WITH FEWER STRANDS, PROVIDED THAT

RECOMMENDED MAXIMUM DEBONDING IN EACH STEM BASED ON THE SPECIFICATIONS AND BEAMS WITH THE MAXIMUM

BRIDGE DESIGN SPECIFICATIONS (ARTICLE 5.9.4.3.3). THE DEBONDED STRAND PATTERNS SHOWN ARE THE

2. DEBONDING OF STRAND IS ALLOWED. FOLLOW THE LATEST PROVISIONS FOR DEBONDING IN THE AASHTO LRFD

1. STRAIGHT STRAND ONLY. DRAPED STRANDS ARE NOT PERMITTED.

5. SEE DETAIL SHEET NEXT 15 FOR UTILITIES SUPPORT DETAILS.

STEM.

4. SHEAR REINFORCING SHOULD BE KEPT TO #4 BARS IN ORDER TO MAXIMIZE THE COVER ON THE SIDE OF THE

CANNOT SUPPORT THE OVERHANG LOADS.

3. THE ADDITIONAL TOP STEEL IN THE BEAM OVERHANGS SHOULD ONLY BE USED WHERE THE WELDED WIRE FABRIC

DESIGNER TO VERIFY THE SIZE OF FABRIC TO RESIST TOPPING LOADS.

BE USED IN PLACE OF THE WWF, PROVIDED THAT THE SPACING OF THE BARS DOES NOT EXCEED 12 INCHES.

THAT EQUIVALENT BARS ARE ADDED ADJACENT TO THE CUT FABRIC. EQUIVALENT MILD REINFORCEMENT MAY ALSO

2. THE WELDED WIRE FABRIC MAY BE CUT TO FACILITATE THE INSTALLATION AROUND THE STIRRUPS, PROVIDED

ACTUAL DECK THICKNESS.

THICK CAST-IN-PLACE DECK. DESIGNERS SHOULD VERIFY THIS REINFORCING FOR EACH DESIGN BASED ON THE

SHOULD BE USED TO SUPPORT THE WET DECK CONCRETE ONLY. THE REINFORCING SHOWN IS BASED ON AN 8"

DECK SHOULD BE DESIGNED TO SPAN BETWEEN STEMS. THE WELDED WIRE FABRIC SHOWN IS PRELIMINARY AND

1. THE TOP FLANGE IS INTENDED TO ACT AS A DECK FORM ONLY. A REINFORCED CAST-IN-PLACE CONCRETE

P

C

I

If

s

u

c

h

s

e

r

v

i

ce

s

a

r

e

r

e

qu

i

r

e

d

,

p

l

ea

s

e

s

ee

k

a

n

a

pp

r

op

r

i

a

t

e

p

r

o

f

e

ss

i

on

a

l

.

on

l

y

.

P

C

I

N

o

r

t

h

ea

s

t

i

s

no

t

r

e

nd

e

r

i

ng

e

ng

i

n

ee

r

i

ng

o

r

o

t

h

e

r

p

r

o

f

e

ss

i

on

a

l

s

e

r

v

i

ce

s

t

h

r

ough

t

h

i

s

gu

i

d

e

li

n

e

.

N

o

r

t

h

ea

s

t

h

a

s

pub

li

s

h

e

d

t

h

i

s

w

o

r

k

w

it

h

t

h

e

und

e

r

s

t

a

nd

i

ng

t

h

a

t

P

C

I

N

o

r

t

h

ea

s

t

i

s

s

upp

l

y

i

ng

i

n

f

o

r

m

a

ti

on

r

e

s

pon

s

i

b

l

e

f

o

r

a

ny

e

rr

o

r

s

,

o

m

i

ss

i

on

s

o

r

d

a

m

a

g

e

s

a

r

i

s

i

ng

ou

t

o

f

t

h

i

s

i

n

f

o

r

m

a

ti

on

.

P

C

I

ob

t

a

i

n

e

d

fr

o

m

s

ou

r

ce

s

b

e

li

e

v

e

d

t

o

b

e

r

e

li

a

b

l

e

.

P

C

I

N

o

r

t

h

ea

s

t

o

r

it

s

m

e

m

b

e

r

s

h

i

p

s

h

a

ll

no

t

b

e

T

h

e

d

e

t

a

il

s

s

ho

w

n

a

r

e

gu

i

d

e

li

n

e

s

a

nd

s

hou

l

d

no

t

b

e

c

on

s

i

d

e

r

e

d

s

t

a

nd

a

r

d

s

.

T

h

e

i

n

f

o

r

m

a

ti

on

h

a

s

b

ee

n

D

I

S

C

L

A

I

M

E

R

:

NO

.

DA

TE

D

E

S

CR

I

P

T

I

ON

R

E

V

I

S

I

ON

S

P

R

E

C

A

S

T

/

P

R

E

S

T

R

E

SS

E

D

C

ON

CR

ETE

I

N

S

T

I

T

U

TE

NO

R

T

H

E

A

S

T

W W W

.

P

C

I

N

E

.

O

R

G

R

SHEET NEXT

NO

R

T

H

E

A

S

T

E

X

T

R

E

M

E

TEE

(

N

E

X

T

)

B

E

A

M

D

ET

A

I

L

S

(

2nd

E

d

iti

on

)

ISSUE DATE: 01/22/2021

BASIS: AASHTO LRFD BRIDGE DESIGN SPEC. - 9th EDTION

NEXT F BEAM

(USE WWF IF POSSIBLE)

BARS TO CENTER OF BEAM

OVERHANG LOADS (TYP) EXTEND

ADDITIONAL REINFORCING FOR

1" RECOMMENDED

MIN. COVER ALLOWED BY AGENCY

OF TOP FLANGE (SEE NOTE 2)

4x4 W4xW4 WWF PLACED AT MID-DEPTH

" (TYP)

2

1

1

+

4"

#4 STIRRUPS (TYP)

#4 STIRRUP (TYP)

" COVER WITH

4

3

1

4 SP @ 2" (TYP)

" (TYP)

2

1

2

4 SP @ 2" = 8" (TYP)

OF EACH STEM

2 STRANDS AT TOP

0"

HORIZONTAL SHEAR RESISTANCE (TYP)

EXTEND STIRRUPS TO PROVIDE

RAKE FINISH

DENOTES POTENTIAL DEBONDED STRAND

SEE DETAIL SHEET NEXT 09

INVERTED U SHAPED BAR.

DOUBLE BARS SHOWN MAY BE COMBINED INTO ONE

6" INSIDE RADIUS OR EQUIVALENT MULTIPLE BENDS.

#5 J BAR (20"x10") END ZONE REINFORCING (TYP)

+

2"

NEXT E BEAM

" (TYP)

2

1

1

1" RECOMMENDED

MIN. COVER ALLOWED BY AGENCY

RAKE FINISH

6" SPACING RECOMMENDED

REINFORCING (TYP)

BOTTOM TRANSVERSE DECK

OF EACH STEM

2 STRANDS AT TOP

4 SP @ 2" (TYP)

" (TYP)

2

1

2

4 SP @ 2" = 8" (TYP)

#4 STIRRUP (TYP)

" COVER WITH

4

3

1

#4 STIRRUPS (TYP)

0"

HORIZONTAL SHEAR RESISTANCE (TYP)

EXTEND STIRRUPS TO PROVIDE

DENOTES POTENTIAL DEBONDED STRAND

SEE DETAIL SHEET NEXT 9

HOOKED BAR CONNECTOR

SEE DETAIL SHEET NEXT 10

INVERTED U SHAPED BAR.

DOUBLE BARS SHOWN MAY BE COMBINED INTO ONE

6" INSIDE RADIUS OR EQUIVALENT MULTIPLE BENDS

#5 J BAR (20"x10") END ZONE REINFORCING (TYP)

NEXT D BEAM

1" RECOMMENDED

MIN. COVER ALLOWED BY AGENCY

#4@6" TOP AND BOTTOM

#4@9" TOP AND BOTTOM (TYP)

90° HOOK

#4 STIRRUPS (TYP)

#4 STIRRUP (TYP)

" COVER WITH

4

3

1

OF EACH STEM

2 STRANDS AT TOP

4 SP @ 2" (TYP)

" (TYP)

2

1

2

4 SP @ 2" = 8" (TYP)

2

"

2

1

/

2

"

0"

1

1

/

2

"

DECK FINISH

DENOTES POTENTIAL DEBONDED STRAND

SEE DETAIL SHEET NEXT 11

6" ON CENTER (TYP).

HOOKED REINFORCING BAR

INVERTED U SHAPED BAR. SEE DETAIL SHEET NEXT 11.

DOUBLE BARS SHOWN MAY BE COMBINED INTO ONE

6" INSIDE RADIUS OR EQUIVALENT MULTIPLE BENDS

OPTIONAL #5 J BAR (20"x10") END ZONE REINFORCING (TYP)

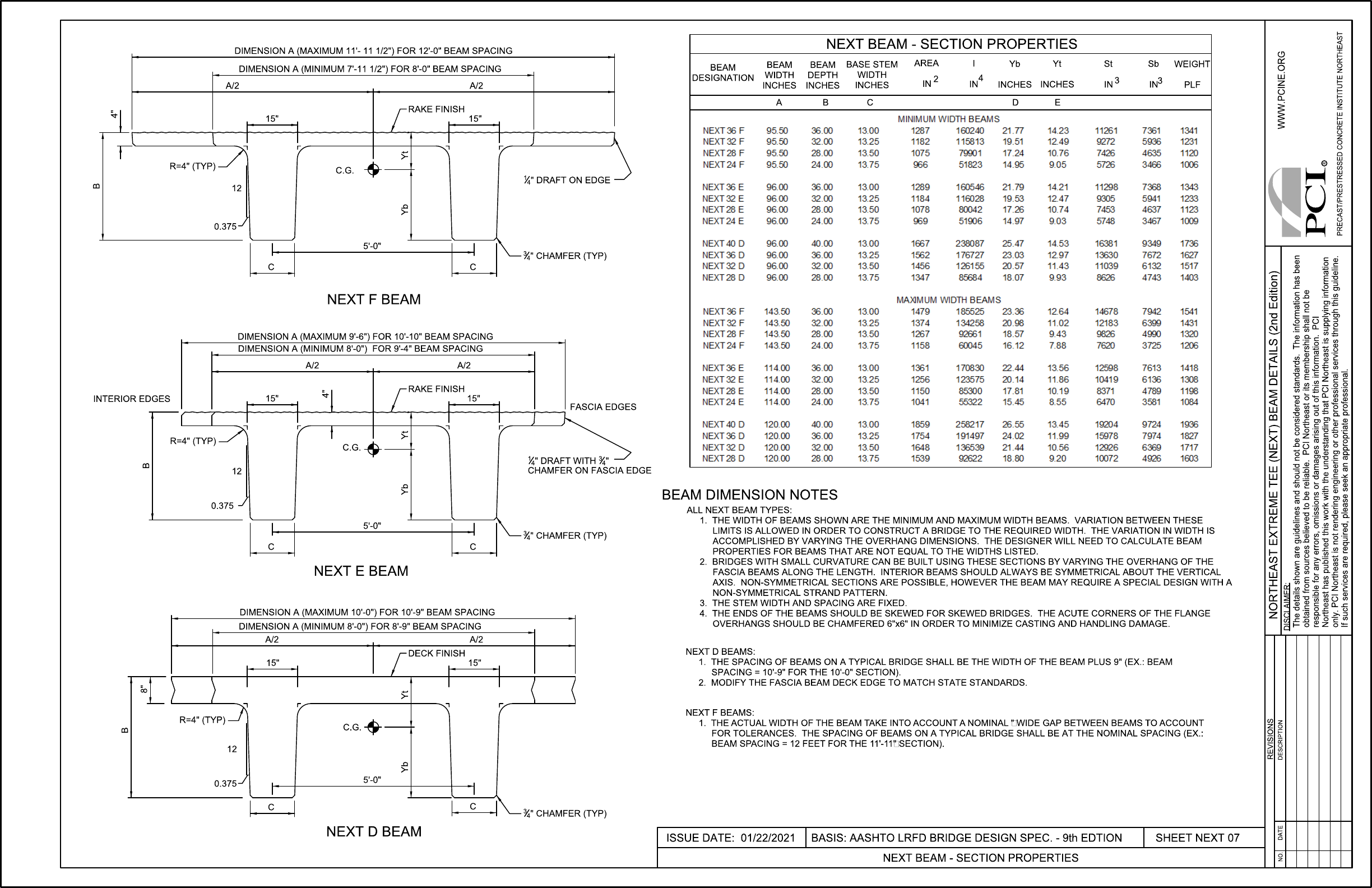

BEAM DIMENSION NOTES

NEXT BEAM - SECTION PROPERTIES

BEAM SPACING = 12 FEET FOR THE 11'-11•" SECTION).

FOR TOLERANCES. THE SPACING OF BEAMS ON A TYPICAL BRIDGE SHALL BE AT THE NOMINAL SPACING (EX.:

1. THE ACTUAL WIDTH OF THE BEAM TAKE INTO ACCOUNT A NOMINAL •" WIDE GAP BETWEEN BEAMS TO ACCOUNT

NEXT F BEAMS:

OVERHANGS SHOULD BE CHAMFERED 6"x6" IN ORDER TO MINIMIZE CASTING AND HANDLING DAMAGE.

4. THE ENDS OF THE BEAMS SHOULD BE SKEWED FOR SKEWED BRIDGES. THE ACUTE CORNERS OF THE FLANGE

3. THE STEM WIDTH AND SPACING ARE FIXED.

NON-SYMMETRICAL STRAND PATTERN.

AXIS. NON-SYMMETRICAL SECTIONS ARE POSSIBLE, HOWEVER THE BEAM MAY REQUIRE A SPECIAL DESIGN WITH A

FASCIA BEAMS ALONG THE LENGTH. INTERIOR BEAMS SHOULD ALWAYS BE SYMMETRICAL ABOUT THE VERTICAL

2. BRIDGES WITH SMALL CURVATURE CAN BE BUILT USING THESE SECTIONS BY VARYING THE OVERHANG OF THE

PROPERTIES FOR BEAMS THAT ARE NOT EQUAL TO THE WIDTHS LISTED.

ACCOMPLISHED BY VARYING THE OVERHANG DIMENSIONS. THE DESIGNER WILL NEED TO CALCULATE BEAM

LIMITS IS ALLOWED IN ORDER TO CONSTRUCT A BRIDGE TO THE REQUIRED WIDTH. THE VARIATION IN WIDTH IS

1. THE WIDTH OF BEAMS SHOWN ARE THE MINIMUM AND MAXIMUM WIDTH BEAMS. VARIATION BETWEEN THESE

ALL NEXT BEAM TYPES:

2. MODIFY THE FASCIA BEAM DECK EDGE TO MATCH STATE STANDARDS.

SPACING = 10'-9" FOR THE 10'-0" SECTION).

1. THE SPACING OF BEAMS ON A TYPICAL BRIDGE SHALL BE THE WIDTH OF THE BEAM PLUS 9" (EX.: BEAM

NEXT D BEAMS:

DESIGNATION

BEAM

INCHES

WIDTH

BEAM

INCHES

DEPTH

BEAM

INCHES

WIDTH

BASE STEM

IN

AREA

2

4

IN

I

INCHES

Yb

INCHES

Yt

IN

St

3

IN

Sb

3

PLF

WEIGHT

A

B C

D

E

07

NEXT BEAM - SECTION PROPERTIES

P

C

I

If

s

u

c

h

s

e

r

v

i

ce

s

a

r

e

r

e

qu

i

r

e

d

,

p

l

ea

s

e

s

ee

k

a

n

a

pp

r

op

r

i

a

t

e

p

r

o

f

e

ss

i

on

a

l

.

on

l

y

.

P

C

I

N

o

r

t

h

ea

s

t

i

s

no

t

r

e

nd

e

r

i

ng

e

ng

i

n

ee

r

i

ng

o

r

o

t

h

e

r

p

r

o

f

e

ss

i

on

a

l

s

e

r

v

i

ce

s

t

h

r

ough

t

h

i

s

gu

i

d

e

li

n

e

.

N

o

r

t

h

ea

s

t

h

a

s

pub

li

s

h

e

d

t

h

i

s

w

o

r

k

w

it

h

t

h

e

und

e

r

s

t

a

nd

i

ng

t

h

a

t

P

C

I

N

o

r

t

h

ea

s

t

i

s

s

upp

l

y

i

ng

i

n

f

o

r

m

a

ti

on

r

e

s

pon

s

i

b

l

e

f

o

r

a

ny

e

rr

o

r

s

,

o

m

i

ss

i

on

s

o

r

d

a

m

a

g

e

s

a

r

i

s

i

ng

ou

t

o

f

t

h

i

s

i

n

f

o

r

m

a

ti

on

.

P

C

I

ob

t

a

i

n

e

d

fr

o

m

s

ou

r

ce

s

b

e

li

e

v

e

d

t

o

b

e

r

e

li

a

b

l

e

.

P

C

I

N

o

r

t

h

ea

s

t

o

r

it

s

m

e

m

b

e

r

s

h

i

p

s

h

a

ll

no

t

b

e

T

h

e

d

e

t

a

il

s

s

ho

w

n

a

r

e

gu

i

d

e

li

n

e

s

a

nd

s

hou

l

d

no

t

b

e

c

on

s

i

d

e

r

e

d

s

t

a

nd

a

r

d

s

.

T

h

e

i

n

f

o

r

m

a

ti

on

h

a

s

b

ee

n

D

I

S

C

L

A

I

M