ELECTRONIC METER REGISTER SYSTEM

CLASS 1 DIVISION 1 and UL/ATEX/IECEx CERTIFIED

REDEFINING

FUEL TRANSFERS

AUTOMATION OF DATA TO ELIMINATE LOSS

VERSATILITY TO MAKE INTEGRATION SIMPLE

SECURITY TO KEEP ASSETS & OPERATIONS SAFE

EMR4 ensures that capturing and transmitting transaction data is seamless and simple. Automated data capture,

whether direct from the EMR4 or via wireless with DataLink, guarantees the integrity of all delivery data and reduces

loss due to antiquated and manual processes.

The EMR4 was designed to simplify operations for its users. With multiple communication ports, programmable relays,

pulse outputs, temperature compensation, On Board Computer (OBC) commands for remote control, and much more

built standard into every register, EMR4 provides the versatility required for integration into any type of application.

EMR4 offers the necessary security to keep your fueling assets safe. With a proprietary operating system and optional

settings to prevent unauthorized access, the EMR4 eliminates tampering and theft and keeps track of every drop of fuel.

Until authorized by built-in password protection or through a peripheral security device, EMR4 will not allow a delivery

without proper authorization, protecting your bottom line.

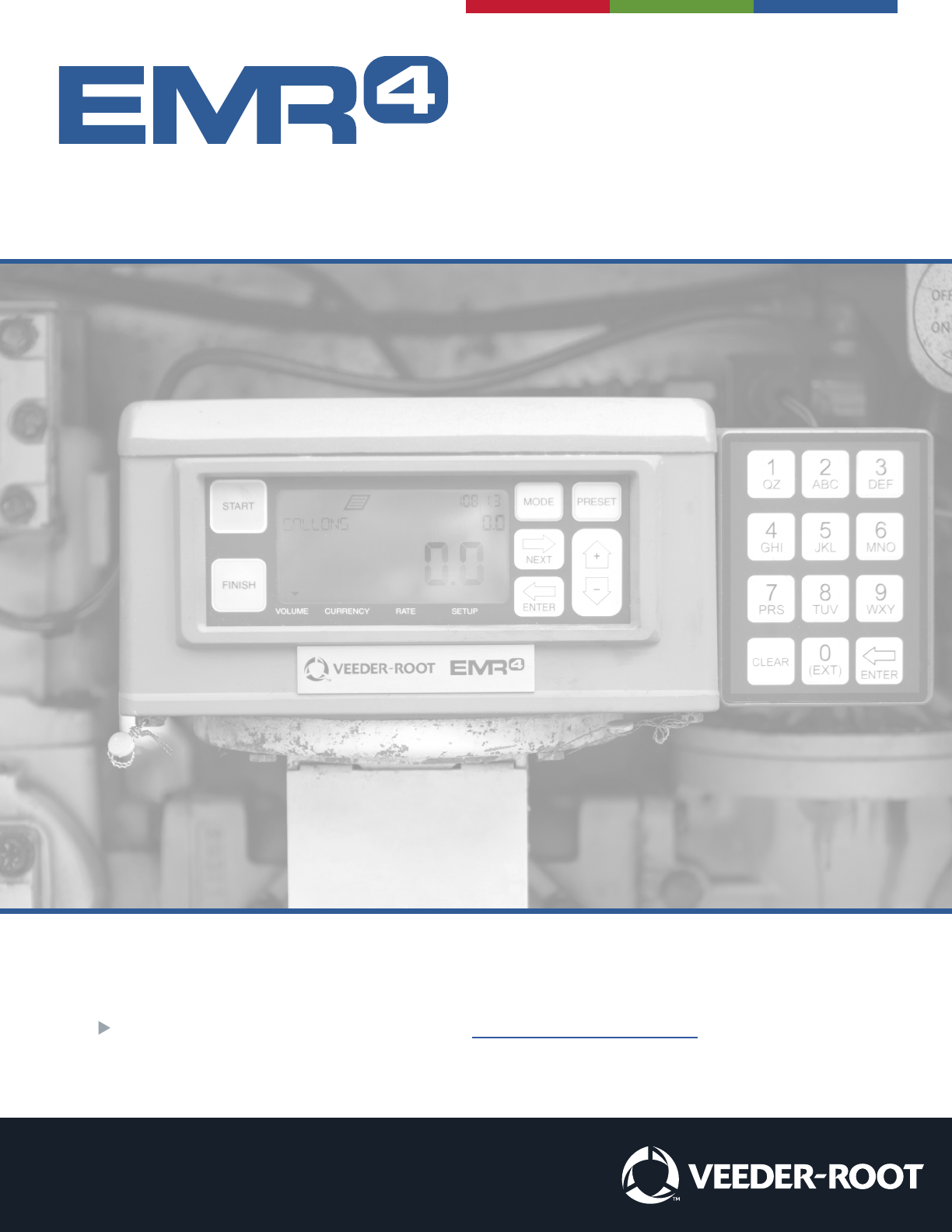

1. Display Head - Installed on the meter or remotely / panel-mounted and driven by an external pulser

2. IB Box - UL/cUL or ATEX/IECEX certied

FOR ALL COMMERICAL AND INDUSTRIAL FUELING APPLICATIONS

2 | www.veeder.com

The EMR4 is designed to be installed or integrated with any meter as a custody transfer approved electronic meter

register for mobile/truck and stationary bulk fueling. The EMR4 system is comprised of two separate components:

These core components, along with an installation kit and a series of optional accessories, allow the user to congure a

system that meets their specic needs on the delivery vehicle, loading rack, or other liquid dispensing application.

EMR4 APPLICATIONS

EMR4 Product Brochure | 3

AVIATION

RAIL

LOADING

DEPOT

REFINED FUELS

DEF

LPG

WIRELESS TRANSACTION

AUTOMATION

The easy to use Veeder-Root DataLink PC-based software provides a data management system that communicates

wirelessly to the EMR4 and generates automatic reports that can be viewed anywhere in the world from any device.

The EMR DataLink wireless data capture solution is the most ecient way to wirelessly manage custody transfers and

inventory reconciliation, perfect for aviation, mobile fueling, and terminal applications, among others. It allows users

to avoid the human error involved in manual ticketing processes where tickets can be easy lost or miswritten. The EMR

DataLink Software works by pulling encrypted transaction data in real time, straight from the meter register and into your

back oce, where it can be viewed securely within a locally hosted database. DataLink sends transaction data from the

meter register to the server automatically, giving you better data going into the back oce more frequently.

This customizable solution can create reports by date, time, customer, or even driver and vehicle, among dozens of other

options. EMR DataLink customization options extend beyond automated reports. Developed from the direct input of major

oil companies, it can be customized to t your business needs. With no recurring fees for use, DataLink is an investment

in technology that can modernize your business’s reconciliation processes and increase manpower eciencies.

Transactions captured

by EMR4

Automatic, wireless data

transmission via DataLink to

your back oce

Advanced reporting.

Data analytics.

Transaction reconciliation

Auto-export to your

accounting or other business

management software for

invoicing and reconciliation

4 | www.veeder.com

1

2

4

3

TECHNICAL FEATURES

EMR4 Product Brochure | 5

CERTIFICATIONS

Global Weights & Measures approval for installation anywhere in the world

UL/cUL, ATEX/IECEx, and PESO certied

Class 1 Division 1 certication for approved installation in all mobile and stationary applications

NMO, NMI, Welmec 7.2 certication

DISPLAY

Dual Register Head System – Simultaneous operation with one IB Box

Remote style display head option available for easy integration into custom installation

Built-in support for multiple languages (ENG, FRA, SPA)

Anti-fog, nitrogen-purged, ultra-bright LED white backlit display

Display head rated for -40° to 60° C

FUNCTIONALITY

Enhanced memory and processing power for fast robust operation

Two RS-232/485 communication ports for easy access to data and remote control

Multi-tier price/tax discount (percentage, at rate, and surcharge)

Wi-Fi support for setup, control, wireless data transmission

System design is adaptable to all meters

Easier programming and data entry with optional keypad

Multiple product deliveries on a single delivery ticket

System labels and delivery tickets are customizable and printable

Free software upgrades available on veeder.com

Removable connectors for easy eld wiring

CONTROL

Electronic temperature compensation

Single or Multi-Point calibration

Store hundreds of transactions in built-in nonvolatile memory

Currency and volume preset deliveries

Daisy chain up to 32 register heads in one network

Built-in USB for software upgrades

Remote emergency start-stop interface

Remote start/stop interface

Three Relay Congurations per Display Head for electronic valve control, pump control, and more

Remote start/stop interface

Three Pulse Outputs per Display Head each with selectable voltage for XL LED displays, additive injection systems, tank level systems and more

DATALINK

Backwards compatible with EMR3 systems

Automatically capture, record and transmit all meter activity to your back oce

Encrypted wireless signal for maximum security

If truck is out of range, transmission automatically resumes once in range

Indoor/Urban range up to 1000 feet

Outdoor line of site range up to 9 miles

900MHZ modem

Direct connect using RS-232

Supply voltage 7 - 28VDC

Generate custom reports and printouts

DISPLAY HEAD FUNCTIONS

6 | www.veeder.com

METER-MOUNTED DISPLAY HEAD REMOTE DISPLAY HEAD

NOTE: Meter-Mounted Display Head and the Remote Display Head have the same screen features.

EMR4 Product Brochure | 7

FEATURE PICTURE DESCRIPTION

START

Push button to begin the delivery. The Nozzle Symbol appears in the upper

left of the display indicating you are ready to dispense fuel. If multiple

products are available for dispensing, select Product by using the arrow keys

and press ENTER.

FINISH

Press button to end fuel dispense transaction. After transaction is complete,

pressing FINISH will clear the display (0.0 in the Register Field).

MODE

Push to cycle between VOLUME, CURRENCY, RATE, and SETUP mode.

Mode Indicator will move in relationship to the MODE button being pressed.

PRESET

Push button to make a preset delivery and PRESET GALLONS displays in place

of GALLONS in the Descriptor Field.

NEXT Press to enter the value elds in SETUP, Product selection or Preset selection.

ENTER

Press to accept selection of parameter or alphanumeric values, or to return to

prior menu selection.

Up (+) and Down (-)

Press buttons to display a preprogrammed preset, or to select another

number. Press ENTER to accept the next preset amount.

Nozzle Symbol

Fuel nozzle icon displayed constantly when system is ready to dispense. The

Icon will ash when approaching the time-out in delivery mode (30 seconds).

Printer Symbol A page icon will display when a printer is congured for the system.

Multiple Delivery Symbol This icon will display when the multiple delivery state is initiated.

Totalizer Field Displays the total amount dispensed through the display head.

Temperature Indicator

This icon will display only when a temperature compensated product is

selected.

Preset Field

Indicates a predetermined amount of fuel or currency to dispense. This value

will count down to zero.

Register Field

Displays the current volume, currency value, nal price, or rate of fuel

dispensed.

Descriptor Field

Rolling text capable of showing extended messages: labels, descriptions, and

error codes.

Mode Indicator

Indicates which mode the display head is currently in: Volume, Currency, Rate,

Setup