|

MALARKEY LAMINATE SHINGLE INSTALLATION INSTRUCTIONS

1

Residential (Building) Code, Section R905.2.8.5, drip edge

ashing (drip edge, eave or rake metal) is required along the

eave and rake edges of shingle roofs.

Install drip edge rst along the eaves, and later on the rakes

once the eld underlayment has been applied.

UNDERLAYMENT

Malarkey makes two types of underlayment, the rst being

water-resistant, mechanically-attached eld underlayments

Right Start

™

UDL and our Secure Start

®

line of synthetic

underlayments.

The second type are waterproof, self-adhering underlay-

ments, Arctic Seal

®

and Secure Start

®

HT products which are

intended for use in cold weather climates that produce ice

dams.

Self-adhering underlayment can also be installed as a ashing

membrane in areas susceptible to leaks such as roof valleys,

roof-to-vertical transitions, and around vents, curbs, skylights

and other roof penetrations.

Underlayment is required on roof decks prior to the installation

of Malarkey shingles. Your geographical location, weather,

degree of roof slope, and type of roof covering will help deter-

mine which Malarkey underlayment is right for your situation.

Consult local building code for additional guidance.

Complete installation instructions are available on our website

at WWW.MALARKEYROOFING.COM.

Other Instructions Common to the Installations that

Follow:

• Underlayment is installed parallel to the eaves.

• End laps in the same course should be 6" (152mm), and

staggered 6' (1.8 m) apart in subsequent courses.

• Extend eld underlayments 6" (152 mm) over hips, ridges

and valleys. Where the roof meets a vertical surface, run

the underlayment a minimum of 3" (76mm) up the wall

and secure.

• Once an expanse of roof is covered by underlayment up

to the ridge, apply drip edge ashing to the rakes, over

the ends of underlayment.

INSTALLATION IN NON-ICE DAM REGIONS

Roof Slopes 4:12 and Greater

Roof slopes 4:12 (4" [102 mm] per 12" [305 mm]) and greater

require the installation of a single (1) layer of Malarkey’s eld

underlayment (or code-compliant equivalent) over the entire

roof deck.

Install the initial course ush to the eave and trim at the rake.

Fasten sufciently to hold the underlayment in place and work

safely until shingles are applied or according to adopted build-

ing code. Secure Start

®

underlayments have bullseye imprints

on the material to act as guides for fastening.

Continue working up the roof, subsequent courses overlap-

ping the preceding by 2"- 4" (51-102 mm), depending on the

type of underlayment being applied. (See Figure 1)

GENERAL INSTRUCTIONS

Install Malarkey laminate shingles according to adopted

building code and local amendments. To qualify for war-

ranty protection and obtain stated coverage, the installa-

tion instructions detailed here must be followed. Contact

Malarkey Technical Services or check our website at WWW.

MALARKEYROOFING.COM for the most current version.

We assume no responsibility when there has been improper

application, failure to properly prepare the surface or provide

proper ventilation according to FHA or HUD minimum prop-

erty standard requirements and adopted building code.

For current warranty information, visit

WWW.MALARKEYROOFING.COM/warranties.

Standard exposure is 5

55

⁄88"(143 mm) to the weather. Offset

between courses is 8" (203mm). Minimum offset for shingle

installation is 4" (102mm).

These step-by-step application instructions apply to standard

slopes/inclines of not less than 4" (102mm) per 12" (305 mm)

or more than 21" (533mm) per 12" (305 mm). For lower

slopes [2" (51mm) to less than 4" (102mm) per 12" (305 mm)]

and steep slopes [more than 21" (533 mm) per 12" (305 mm)],

modify the installation as described below. Do not apply

shingles on roofs having a slope less than 2" (51 mm) per 12"

(305mm).

Note: The lm strips on each shingle, front and back, prevent

shingles from sticking together while in the bundle and are not

designed to be removed.

IMPORTANT

• ALWAYS wear fall protection when working on a roof.

• Underlayments can be slippery, particularly when wet or

covered with frost. Be careful when walking on them.

Ventilation: To prevent harmful condensation or heat buildup,

air must circulate freely under the roof deck. Install roof vents

at ridges and eaves. Ventilation provisions must meet or

exceed current FHA or HUD requirements and adopted build-

ing codes.

Roof Deck: The surface to receive the new roong should be

in good shape and solidly sheathed, constructed of a mini-

mum

33

⁄88" (10 mm) thick, exterior-grade plywood,

77

⁄1616" (11 mm)

thick oriented strand board (OSB), or seasoned lumber,

nominally 1" (25 mm) thick. Boards should be positioned

tight to each other and securely nailed to framing members.

Deteriorated or rotted boards should be replaced. For exces-

sively resinous areas and loose knots, cover with sheet metal

patches.

Malarkey strongly recommends installing sheathing when

wood board decking is the existing substrate. Problems with

the performance of your roong system, such as leaks and

buckling, increase if installed directly over wood board decks.

Failure to use properly conditioned deck materials can result

in deck movement which can damage the roof covering and

may void your warranty.

Drip Edge Flashing: In accordance with 2018 International

Building Code, Section 1507.2.8.3, and 2018 International

Directions for Applying

Malarkey Laminate Shingles

|

MALARKEY LAMINATE SHINGLE INSTALLATION INSTRUCTIONS

2

When choosing this option, make sure proper ventilation and

moisture control issues are addressed.

INSTALLATION IN ICE DAM REGIONS

Roof Slopes 4:12 and Greater

In geographic regions that experience the possibility of ice

dams along the eaves (or if required by building code), install

a full-width sheet of self-adhering underlayment (or equivalent

underlayment conforming to ASTM D1970) along the eaves.

Continue installing self-adhering underlayment up and out

onto the roof no less than 24" (610 mm) past the inside, warm

interior wall of the house or above the expected level of ice

dams or according to building code requirements.

If additional courses of self-adhering underlayment are nec-

essary to reach that point, course lap guide lines (lay lines) on

the sheets show how far to lap the material. Firmly hand-roll

these overlaps to ensure a complete, watertight bond.

Once past 24" (610 mm), follow with full-width courses of

your specied eld underlayment, the rst course lapped 6"

(152 mm) over the termination of self-adhering underlayment

and the rest with 2"- 4" (51-102 mm) side laps, depending on

the type of underlayment being applied. Lay lines show how

far to lap the material.

Fasten as described above.

For extra protection at the eaves and prior to the installation

of drip edge, install a 6"-wide (152 mm) stripping ply of Arctic

Seal

®

, and ensure it covers the junction of roof and fascia.

(See Figure 3)

SINGLE LAYER OF

SELF-ADHERING

UNDERLAYMENT

ON EAVES;

RECOMMENDED ON RAKES

EAVE METAL

RAKE METAL

INSTALLED ON TOP

OF UNDERLAYMENT

SINGLE LAYER OF

SPECIFIED

UNDERLAYMENT

ROOF DECK

MIN. 6"-WIDE

SELF-ADHERING

UNDERLAYMENT

INSTALLED

UNDERNEATH EAVE METAL

(OPTIONAL)

24" MIN

24" MIN

6" OVERLAP

FULL-WIDTH

SHEETS

2" - 4" OVERLAP

DEPENDING ON

PRODUCT

Figure 3 - Application of Self-Adhering and Field Underlayments

on Roof Slopes 4:12 and Greater (IceDam Regions)

Roof Slopes 2:12 Up to 4:12

Like 4:12 and greater slopes, begin with a full-width sheet

of self-adhering underlayment (or equivalent compliant with

ASTM D1970) along the eaves.

Continue application up and out onto the roof as necessary to

a point not less than 24" (610 mm) past the inside, warm inte-

rior wall of the house or above the expected level of ice dams

or according to building code requirements.

Once that point is reached, switch to double layers of your

specied eld underlayment, the rst course a half-width

starter strip lapped 6" (152 mm) over the termination of

self-adhering underlayment.

2" - 4" OVERLAP

DEPENDING ON

PRODUCT

FULL-WIDTH

SHEETS

ROOF DECK

EAVE METAL

SINGLE LAYER OF

SPECIFIED

UNDERLAYMENT

RAKE METAL

-INSTALLED ON TOP

OF UNDERLAYMENT

Figure 1 - Application of Field Underlayment on Roof Slopes 4:12

and Greater (Non-Ice Dam Regions)

Roof Slopes 2:12 Up to 4:12

Install a double layer of any Malarkey underlayments. If local

building code has adopted 2015 or later IBC or IRC, a single

layer of ASTM D1970 underlayment (Arctic Seal

®

, Secure

Start

®

HT) is acceptable as an exception per the I-Codes.

For a double layer, start at a lower corner of roof and begin

by applying a half-width starter strip of eld underlayment (or

code-compliant equivalent) along the eaves.

Succeeding courses are all full-width, the rst course com-

pletely overlapping the starter, and followed by courses half-

lapped over preceding courses, on up the roof.

Fasten sufciently to hold in place and work safely until shin-

gles are applied or according to adopted building code. (See

Figure 2)

ROOF DECK

STARTER

STRIP

EAVE METAL

FULL-WIDTH

SHEETS

RAKE METAL

INSTALLED ON TOP

OF UNDERLAYMENT

DOUBLE LAYER

OF

SPECIFIED

UNDERLAYMENT

Figure 2 - Application of Field Underlayment on

Roof Slopes 2:12 Up to 4:12 (Non-Ice Dam Regions)

Optional installation for low slope roofs: For superior pro-

tection in coastal regions, areas of wind-driven rain, or homes

with double-slope construction, the roof deck can be covered

with a double layer of Arctic Seal

®

self-adhering underlayment

or equivalent conforming to ASTM D1970.

|

MALARKEY LAMINATE SHINGLE INSTALLATION INSTRUCTIONS

3

Nailing Pattern: Under normal conditions, use four (4) fasten-

ers for each full shingle.

Malarkey laminate shingles feature The Zone

®

, an enlarged,

1

5

/16" (33 mm) wide nailing area that helps ensure correct fas-

tener placement. Place fasteners in this nailing area approx-

imately 1" (25 mm) in from each edge and the remaining

fasteners evenly spaced between. (See Figure 6)

5-5/8"

8"

EVENLY SPACED

Figure 6 - Laminate, 4-Nail Fastening Pattern

Wind Resistance and Hand-Sealing: Malarkey shingles are

manufactured with strips of a factory-applied, thermal sealant

that is activated by the heat of the sun after the shingle is on

the roof. Exposure to the sun’s heat bonds each shingle to the

one below for wind resistance.

A variety of conditions like cold weather, high winds or blow-

ing dust, however, can affect the ability of the sealant strip

to activate and prevent shingles from self-sealing during, or

shortly after, installation. If shingles have not sealed after a

reasonable time period, hand-sealing (also called hand-tab-

bing) is strongly recommended.

Note: Malarkey’s wind warranties apply only when shingles are

sealed, whether by hand-sealing or activation of the self-seal-

ing strips. Failure to seal under adverse circumstances like

those described above is not a manufacturing defect.

To hand-seal a shingle, apply four (4) quarter-size dabs of

asphalt roof cement conforming to ASTM D4586 evenly

spaced under each shingle, and press shingles rmly into the

cement. Excessive use may cause blistering; correct amounts

should not bleed out from under the shingle. (See Figure 7)

5-5/8"

8"

EVENLY SPACED

Figure 7 - Hand-Sealing Laminate Shingles

Steep Slope Fastening of Laminate Shingles: Roof decks

with slopes greater than 21" (533 mm) per 12" (305mm)

require installation with six (6) fasteners per shingle and

hand-sealing underneath.

Two methods for fastening can be used, but for each, the

outer fasteners must be placed in the nailing area approxi-

mately 1" (25mm) in from each edge. The rst method has the

remaining four (4) fasteners also placed in the nailing area and

evenly spaced between. (See Figure 8)

Succeeding courses are full-width, the rst course completely

overlapping the starter, and followed by courses half-lapped

over preceding courses, on up the roof.

Fasten as described above. (SeeFigure 4)

EAVE METAL

ROOF DECK

DOUBLE LAYER

OF SPECIFIED

UNDERLAYMENT

RAKE METAL

INSTALLED ON TOP

OF UNDERLAYMENT

MIN. 6"-WIDE

SELF-ADHERING

UNDERLAYMENT

INSTALLED

UNDERNEATH EAVE METAL

(OPTIONAL)

SINGLE LAYER OF

SELF-ADHERING

UNDERLAYMENT

ON

EAVES; RECOMMENDED

ON RAKES

6" OVERLAP

STARTER

STRIP

24" MIN

24" MIN

Figure 4 - Application of Self-Adhering and Field Underlayments

on Roof Slopes 2:12 Up to 4:12 (Ice Dam Regions)

SHINGLE FASTENING

Type of Fasteners: Fasteners must be minimum 12-gauge

(0.105inch [3 mm]) shank, galvanized steel, stainless steel,

aluminum or copper roong nails, with a

33

⁄88" (10mm) head,

compliant with ASTM F1667, and long enough to penetrate

through all layers of roong materials and at least ¾" (19 mm)

into the roof sheathing. Where the roof sheathing is less than

¾" (19 mm) thick, the fasteners shall penetrate through the

sheathing.

Malarkey approves the use of hand-nailing and/or pneumatic

nailers for applying fasteners, but nails must be driven ush

to the shingle surface and not overdriven, underdriven or

driven at an angle, especially on low slope installations where

water runs off less freely and leaks could result. When fasten-

ing adjacent shingles, butt them loosely together to prevent

buckling.

The use of staples is not an approved fastening method.

(SeeFigure 5)

Properly Driven Improperly Driven

Asphalt shingles

Decking

Underdriven

⅜" (10 mm)

min. diameter

Straight, good

penetration, and flush

with shingle surface.

Inadequate deck

penetration.

Too deep, cuts

into shingle.

Inadequate

anchorage.

Overdriven Crooked

Figure 5 - Nailing Instructions

|

MALARKEY LAMINATE SHINGLE INSTALLATION INSTRUCTIONS

4

the remaining two evenly spaced on the same line as the end

fasteners. Do not place fasteners in the seal-down strip.

Continue across the eave with full-length starter shingles,

butting them loosely together to prevent buckling.

First Course of Shingles: Start the rst course with a full-

length shingle laid directly over the starter course.

Begin at the same lower corner of roof and apply ush with

the edges of the starter course on both eave and rake sides

(maintaining the ¼"- ¾" [6 -19 mm] roof overhang).

Fasten as described in the Shingle Fastening section above.

Second through Succeeding Courses: Start the second

course with a shingle from which 8" (203 mm) has been cut

from one end.

Position the remaining piece over the underlying, rst course

shingle, and align the bottom edge along a line level with the

“sawtooth” overlay, leaving an exposure of 5

55

⁄88" (143 mm).

Secure with fasteners.

Courses three through ve are begun with partial shingles,

each progressively 8" (203 mm) shorter, establishing the over-

all diagonal pattern. Pieces cut from shingles along the left

rake can be used either to continue the diagonal installation

pattern or nish off courses at the right rake.

Apply a full-length shingle adjacent to each of the rst ve

courses to extend the pattern. Join the shingles loosely

together to prevent buckling. Butt factory edge to factory

edge when installing the stairstep method. This helps maintain

a straight layout of the remaining shingles.

The sixth course begins again with a full length shingle, so

repeat the 1-to-5 course cycle on up the roof.

Shingles may be laid from either lower corner of roof;

follow layout and cutting instructions as required for proper

application.

Note: Other shingle offsets are acceptable but no less than 4"

(102 mm). Straight up application of shingles, or racking, is not

recommended.

(See Figure 10)

1

4

5

2

3

COURSES 1-5

1: FULL LENGTH

2-5: EACH PROGRESSIVELY 8"

SHORTER (

MIN 4")

Figure 10 - Laminate Shingle Layout Pattern

CONSTRUCTING ROOF VALLEYS

Similar to a roof deck being prepared for shingles by rst

applying an underlayment, roof valleys must be likewise pre-

pared before they can be “constructed” with shingles.

Closed-cut and Open Metal Valley applications are recom-

mended for laminate shingles (instructions to follow); the Open

Membrane Valley style is also acceptable.

Valley Underlayment: Center a full-width strip of self-adher-

ing underlayment (or equivalent conforming to ASTM D1970)

5-5/8"

EVENLY SPACED

8"

Figure 8 - Laminate, 6-Nail Fastening Pattern

The second, alternate way has the interior fasteners as indi-

cated to accommodate shingle offsets and ensures no nail is

less than 2" (51 mm) from the joint of the underlying shingles.

(See Figure 9)

5-5/8"

8"

12" 12"

2"2"

Figure 9 - Laminate, 6-Nail Alternate Fastening Pattern

Note: See Malarkey’s Shingle and Accessory Warranty online

for any additional requirements related to specic coverages.

SHINGLE PATTERN LAYOUT AND APPLICATION

Important: The diagonal application procedures described

below are necessary to prevent objectionable patterning.

Malarkey is not responsible for such patterning on roofs where

this diagonal application is not used. Exposures should be

even along the courses as well, or an objectionable appear-

ance may occur.

Malarkey Smart Start

®

Starter Shingles: Smart Start

®

starter

shingles are designed to be separated lengthwise at a per-

foration so you get two, full-size starter shingles in one. The

perforation is in the middle of the shingle, 8

3

⁄16" (208 mm) from

each edge, and both pieces have seal-down strips. Besides

eaves, it is recommended Smart Start

®

starter shingles be

installed on the rake edges of roof to provide a clean edge

and increase wind resistance.

LAMINATE SHINGLE PATTERN LAYOUT (8" [203 MM]

OFFSET, FIVE COURSE DIAGONAL METHOD)

Starter Course: Install Malarkey Smart Start

®

starter shingles

or equivalent conforming to ASTM D3462. Ensure they are

positioned with the factory-applied sealant strip face up and

the strip adjacent to the eave edge of roof.

Cut 6" (152 mm) off one end of the rst starter shingle, and lay

it on a lower corner of the roof, overhanging the rake and eave

edges by ¼"- ¾" (6 -19 mm).

Fasten with 4 nails, 1½"- 3" (38-76 mm) up from the eave,

with one fastener 1" (25 mm) from each side of the starter and

|

MALARKEY LAMINATE SHINGLE INSTALLATION INSTRUCTIONS

5

Open Metal Valley Construction: Metal valley ashing

(“valley metal”) used with Malarkey shingles must be minimum

24" (610 mm) wide and 26 gauge. Preformed, “W”-shaped

ashing is recommended.

Center the valley metal over the valley liner, press it into the

break of the valley, and secure with fasteners no more than 1"

(25 mm) from the outside edges at a spacing of 10" (254 mm)

to 12" (305 mm) O.C.

Set overlapping ends of the valley metal in a continuous bead

of sealant, achieving a lap of 4" (102 mm). DO NOT FASTEN

THE METAL LAP.

For additional sealing, a continuous 6" (152 mm) strip of

self-adhering Arctic Seal

®

may be applied over the fasteners

on each side of the valley metal.

Never use a shingle trimmed to less than 12" (305 mm) in

length to nish a course running into a valley. If necessary,

trim a tab off the adjacent shingle in the course to allow a

longer portion to be used. Make sure each shingle extends far

enough into the valley so in a future step, a shingle’s full width

(or height) will be trimmed back.

Nail no closer than 6" (152 mm) to the valley centerline.

Now, trim shingles a minimum of 2" (51 mm) back from the

centerline, cut the ends diagonally to match the centerline

angle, and crop the top of each shingle at a 1" (25 mm), 45

degree cut.

Embed the ends of the cut valley shingles in a continu ous

3" (76 mm) wide bead of asphalt roof cement conforming to

ASTM D4586, and press them into the adhesive.

(See Figure 12)

1

2

1. CUT TO MATCH CENTERLINE ANGLE.

2. TRIM TOP 1" 45 DEGREES TOWARDS VALLEY.

SMART START

STARTER SHINGLE

8" OFFSET (MIN 4")

TRIM SHINGLES 2"

FROM CENTERLINE

DECK

SHINGLES SET IN A

3" WIDE BEAD OF

MASTIC/SEALANT

OPTION: CLIPS OR CLEATS

8" TO 24" APART. BEND CLIP

OVER NAIL HEADS. FOR VALLEY

METAL WITH CRIMPED EDGE.

VALLEY METAL

VALLEY LINER

APPLY STRIPPING

PLY OF ARCTIC

SEAL TO EDGES

OF VALLEY METAL

*

UNDERLAYMENT WOVEN THROUGH

VALLEY

(MAY ALSO BE APPLIED TO

VALLEY LINER BY A MINIMUM 6" LAP)

Figure 12 - Open Metal Valley Application

FLASHING APPLICATIONS

Intersections of Roof and Vertical Sidewall: Minimum

26-gauge, metal step ashing is used in the junction between

a sloping roof and intersecting sidewall (on a dormer, for

example) to protect this vulnerable area from moisture

intrusion.

Step ashing can be square or rectangular, but 8-inch

(203 mm) by 8-inch (203 mm) dimensions are common and

satisfactory for our purposes.

Being 8" wide allows the ashing to be bent at 90 degrees

and pushed against the transition of roof to wall, the horizon-

tal ange extending 4" (127 mm) out onto the roof deck and

the vertical ange, 4" (127 mm) up the wall assembly. Being

in the valley, and apply it directly to the roof deck. Ensure this

valley liner is tight to the deck without bridging in the center of

the valley.

Field underlayment can be woven across the valley liner and

up the opposite side at least 12" (305 mm) or lapped over

each side a minimum of 6" (152 mm). When fastening, be

aware no fasteners are allowed within 6" (152 mm) of the

valley centerline.

Valley underlayment must be in place for each method

described next.

Closed-Cut Valley Construction: Lay a rst course of

shingles along the eave on one side of the roof, and continue

it across the valley and onto the adjoining roof at least 12"

(305mm). Do not make a joint in the valley. Should a shingle

fall short, add-in one or two tab sections so the joint falls out-

side the line of the valley.

Press the shingles well into the break of the valley, and nail

using normal fastening methods, remembering no fasteners

are allowed closer than 6" (152 mm) to the valley centerline.

Besides the nails used to secure the shingle, add another

in the upper corner at the end of each shingle crossing the

valley.

Repeat these procedures with the rst course of shingles on

the intersecting roof, extending it across the valley, over the

top of the shingles laid before, and at least 12" (305 mm) onto

the adjoining roof surface. Press into the valley, and fasten as

before.

Note: The rst course of shingles are the only ones woven in

this fashion.

Return to the side of the roof you began with, and resume

laying shingle courses across the valley and onto the adjoining

roof at least 12" (305 mm). Complete the installation of shin-

gles on that roof section.

Snap a chalk line 2" (51 mm) from the centerline of the valley

on the unshingled side. Begin applying shingle courses on the

unshingled side, trimming them diagonally at the chalk line to

match the centerline angle, and cropping the upper corner of

the last shingle at a 1" (25 mm), 45 degree cut. Doing this will

direct water into the valley.

Embed the ends of the cut valley shingles in a continu ous

3" (76mm) wide bead of asphalt roof cement conforming to

ASTM D4586, and press them into the adhesive.

Complete the installation of shingles on that roof section.

(SeeFigure 11)

DECK

8" OFFSET (MIN 4")

1. CUT TO MATCH CENTERLINE ANGLE.

2. TRIM TOP 1" 45 DEGREES TOWARDS VALLEY.

1

2

SHINGLES SET IN A BEAD

OF MASTIC/SEALANT

VALLEY LINER

SMART START

STARTER SHINGLE

TRIM SHINGLES 2"

FROM CENTERLINE

EXTEND SHINGLES A MINIMUM

OF 12" THROUGH VALLEY.

-FASTEN THE ENDS WITH A

NAIL IN UPPER CORNER.

COVER STARTER

BY WEAVING

FIRST COURSE

UNDERLAYMENT WOVEN

THROUGH VALLEY (MAY ALSO

BE APPLIED TO VALLEY LINER

BY A MINIMUM 6" LAP).

Figure 11 - Closed-Cut Valley Application

|

MALARKEY LAMINATE SHINGLE INSTALLATION INSTRUCTIONS

6

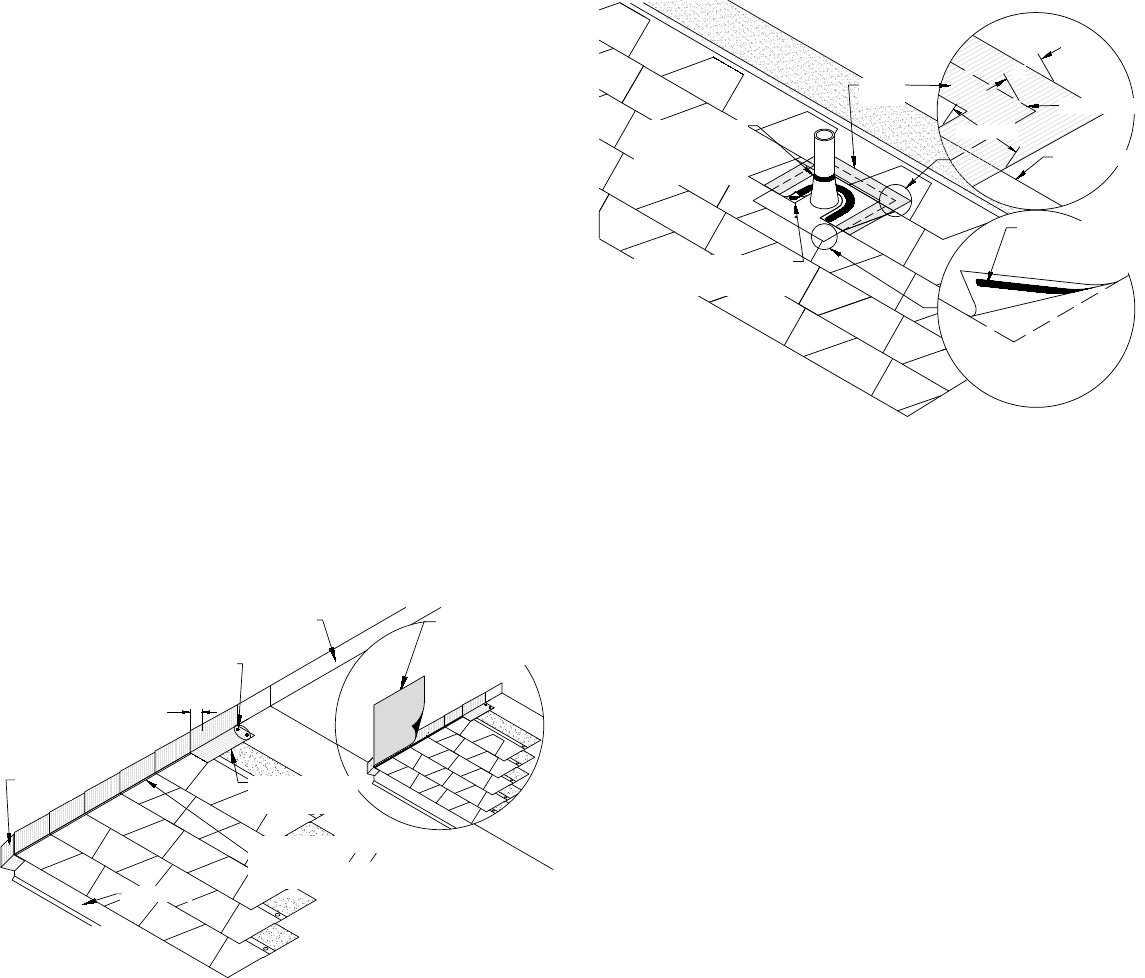

Vent Pipe (and Other Flanged Penetration) Flashing:

Install shingle courses up to the vent pipe, and cut a hole in

the shingle to be positioned over the pipe. Install the pipe jack

or boot (top and side anges may be set in sealant).

Additional, optional weatherproong: Unexposed pipe jack

anges (top and both sides) may also be stripped-off with

minimum 6" (152 mm) wide Arctic Seal

®

, covering all fasteners

used to secure the anges, and tying onto the eld underlay-

ment a minimum of 3" (76 mm).

Continue roong around the pipe, cutting shingles to t on the

sides and top of the pipe jack anges. Ensure shingles extend

beyond the downslope side of the pipe itself. Shingles that

overlap any part of the anges should be sealed to the ange

with asphalt roof cement conforming to ASTM D4586. Correct

amounts should not bleed out from under the shingles; exces-

sive use may cause blistering. Apply pressure to seal.

(See Figure14)

CUTAWAY

VIEW

6" MINIMUM

FLANGE EDGE

SEAL UNDERSIDE

OF FLANGE ALONG THE

TOP AND BOTH SIDES

SHINGLE EDGE

SEAL SHINGLE TO FLANGE

WITH BEAD OF MASTIC

OR SEALANT

INSTALLATION OF A

STORM COLLAR OR

SEALANT IS

REQUIRED TO SEAL

ALL PIPE FLASHINGS

ARCTIC

SEAL

3"

Figure 14 - Vent Pipe Flashing Application

Cap (Counter) and Chimney Flashings: The metal ashing

apron for the front of the chimney shall be installed over the

last course of shingles below the chimney and its vertical

ange extending up the face of the chimney.

The metal ashings of chimneys, skylights, vents, and adjoin-

ing walls must be counter-ashed with sheet metal cap

ashing.

Cap ashing (also called counter ashing) should originate in

the masonry mortar joints of the chimney and be mortared-in

or caulked with urethane sealant to ensure a watertight

connection.

Cap ashing should then turn down the chimney and extend

a minimum of 2" (51 mm) over the step ashings at all roof-to-

sidewall intersections. (See Figure 15)

8" long allows individual step ashing pieces to overlap each

other in water-shedding fashion as they are installed.

Individual step ashing pieces are integrated with each course

of shingles as they are applied to intersect the sidewall. A ¼"-

¾" (6 -19 mm) gap between the shingles and vertical bend of

the ashing is recommended.

To allow for possible roof movement, fasten each piece of

ashing to the roof deck and not the sidewall.

Installation is as follows: Atop the Smart Start

®

starter

course at the eave, place the rst piece of ashing*. The hori-

zontal ange should be ush with the eave edge of the starter

and the vertical ange against the sidewall, counter-ashed by

the wall cladding.

Fasten the horizontal ange of the step ashing to the roof

deck with two nails placed 1" (25 mm) from the upper edge

and spaced an equal distance apart.

Lay a rst course shingle down on the roof, positioning it close

to the sidewall but leaving a ¼"- ¾" (6-19 mm) gap between

the end of the shingle and vertical bend in the step ashing.

Fasten in place. The horizontal ange of the ashing will no

longer be visible, but you can still see the vertical ange along

the sidewall.

Place the second step ashing atop the rst course shingle,

and position it up from the eave edge of the shingle, matching

the shingle exposure, and fasten as before.

Lay a second course shingle on the roof, position leaving a

gap, and fasten.

Place the third step ashing atop that, overlapping the end

of the previous step ashing at the point of shingle exposure

(overlap is typically 2" [51 mm]).

Continue like this on up to the top of the sidewall intersec-

tion, alternating between the placement of step ashing and

shingles.

* The “rst piece of ashing” in this instance might well be

“kickout” ashing, a piece of ashing cut and angled to direct

water out and away from the side of a structure.

To accommodate the angled part, yet still serve as the initial

piece of step ashing, the kickout will likely have a greater

length than a regular piece of ashing. Otherwise, the instal-

lation of shingles and step ashing to follow is the same.

(SeeFigure 13)

NAIL FLASHING PIECE TO

THE ROOF AT THE TOP

EDGE WITH ROOFING NAILS

TURN UNDERLAYMENT

UP AT CHANGE OF PLANE

3" MINIMUM.

2" MIN.

OVERLAP

WEATHER RESISTANT

BARRIER COVERS

VERTICAL FACE OF

THE STEP FLASHING

KICKOUT

FLASHING

EAVE METAL

STEP FLASHING

INTEGRATED

WITH EACH SHINGLE

SHINGLES SHOULD BE

INSTALLED WITH A

1

4

" -

3

4

"

GAP FROM THE VERTICAL

BEND OF FLASHING

Figure 13 - Step Flashing Application at

Roof-to-Sidewall Transitions

|

MALARKEY LAMINATE SHINGLE INSTALLATION INSTRUCTIONS

7

Malarkey hip and ridge shingles also include a factory-ap-

plied, thermally activated seal-down adhesive that provides

additional protection against blow-off. When applied in cold

weather or a windy location, however, it is recommended each

ridge shingle be hand-sealed under each lower corner with a

quarter-size spot of asphalt roof cement conforming to ASTM

D4586.

To avoid damage to hip and ridge shingles in cold weather,

Malarkey recommends warming them sufciently to prevent

damage during installation.

Apply Malarkey hip and ridge shingles beginning at the

bottom of the hip or from the end of the ridge opposite the

direction of prevailing winds.

Snapping a chalk line will help maintain a straight line while

installing ridge shingles.

LOW-PROFILE INSTALLATION (10" AND 12" RIDGEFLEX

®

HIP AND RIDGE SHINGLES)

Prepare for application by separating each hip and ridge

shingle at the perforations: The 10" RidgeFlex

®

produces

four (4) individual hip and ridge strips (see Figure 17), and the

12" RidgeFlex

®

produces three (3) (see Figure 18). Note the

seal-down strips.

SEAL-DOWN

PERFORATIONS

337 mm

13¼"

9

7

⁄8"

251 mm 251 mm 251 mm 251 mm

9

7

⁄8" 9

7

⁄8" 9

7

⁄8"

Figure 17 - 10" RidgeFlex

®

Hip and Ridge Shingle

12"

305 mm 305 mm 305 mm

337 mm

12" 12"

13

¼

"

SEAL-DOWN

PERFORATIONS

Figure 18 - 12" RidgeFlex

®

Hip and Ridge Shingle

Each scored strip is 13¼" (337 mm) tall and has an exposure

of 5

55

⁄88" (143 mm). You will be installing these individual pieces,

and all are installed sealant side up.

Detail drawings to follow in this section show the installa-

tion of hip and ridge shingles along a roof ridge, but hips are

essentially the same. Application begins at the bottom of the

hip or from the end of the ridge opposite the direction of pre-

vailing winds with a hip and ridge starter shingle.

RidgeFlex

®

Starter Shingle: Create a starter shingle by

cutting off the 5

55

⁄88" (143 mm) exposed portion of a RidgeFlex

®

4" MIN

4" MIN

STEP FLASHING-

LAPPED 1" BEYOND

CORNER OF CHIMNEY

BACKER OR CRICKET

FLASHING

COUNTER FLASHING

APRON FLASHING

WITH HEMMED

EDGE

UNDERLAYMENT

TURNED UP WALL

3" MINIMUM

FASTENERS POSITIONED

APPROXIMATELY 12" O.C.

Figure 15 - Chimney Apron and Cap Flashing Applications

Chimney Saddles and Crickets: Apply Arctic Seal

®

self-ad-

hering underlayment (or equivalent conforming to ASTM

D1970) atop chimney saddles prior to the installation of ash-

ing assemblies.

Flashing for chimney saddles and crickets shall be minimum

26-gauge galvanized or stainless steel, designed to cover

the entire surface, and extend vertically 4" (102mm) up the

chimney.

Install a bead of mastic on the edges of chimney saddles and

crickets. Press overlapping shingle courses into the mastic to

seal. Seal all relief cuts and corners. (See Figure 16)

BACKER FLASHING

4" MIN.

SELF-ADHERED

UNDERLAYMENT

INSTALLED UNDER

FLASHING AND

TURNED UP WALL

3" MIN.

FASTENERS

POSITIONED

APPROXIMATELY

12" O.C.

18"

SHINGLE LINE

2"

CRICKET FLASHING

4" MIN.

4" MIN.

18"

FASTENERS

POSITIONED

APPROXIMATELY

12" O.C.

SHINGLE LINE

2"

SELF-ADHERED

UNDERLAYMENT

INSTALLED UNDER

FLASHING AND

TURNED UP WALL

3" MIN.

4" MIN.

4" MIN.

4" MIN.

NOTES:

-FOR WIDTHS MORE THAN 30", CRICKET FLASHING IS REQUIRED.

-ALL FLASHING METAL TO BE A MINIMUM 26 GAUGE.

-A

1

4

" -

3

4

" GAP BETWEEN THE SHINGLE AND VERTICAL BEND OF ALL FLASHINGS IS

REQUIRED.

-SHINGLES HELD BACK 2" FROM BACKER OR CRICKET, BEAD OF MASTIC APPLIED

TO UNDERSIDE OF SHINGLES 1"- 2" UP FROM SHINGLE LINE.

-STRIP-OFF FLANGES (RECOMMENDED) WITH MINIMUM 6" WIDE ARCTIC SEAL.

-ROOF COVERING, STEP AND COUNTER FLASHING OMITTED FOR CLARITY.

CHIMNEY BACKER AND CRICKET FLASHINGS

STEEP SLOPE 20

SCALE: NOT TO SCALE

PROJECT NO:

OWNER:

SUBMITTAL NO. :

DATE:

ADDRESS:

DRAWING NO. :

PROJECT NAME:

Rev. 8/22

Figure 16 - Chimney Saddle and Cricket Flashing Applications

HIPS AND RIDGES

Factory-produced, Malarkey hip and ridge shingles are

recommended for all Malarkey shingle roofs and required for

expanded warranty coverage. Some contractors adapt 3-tab

roong shingles to use as hip and ridge shingles, but Malarkey

only allows this when the eld shingle is also a 3-tab shingle.

Shingles with Scotchgard

™

Protector from 3M require hip and

ridge shingles with Scotchgard

™

Protector be installed with

them. All four of Malarkey’s hip and ridge shingle types feature

this algae-resistant protection.

|

MALARKEY LAMINATE SHINGLE INSTALLATION INSTRUCTIONS

8

Figure 21 - Paint Line in Headlap Area of Shingle Is Opposite the

Exposed Portion

Continue installing hip and ridge shingles, maintaining the

exposure of 5

55

⁄88" (143 mm) and fastening with one nail on each

side and 1" (25 mm) up from the edge so succeeding shingles

conceal nailheads. (See Figure 22)

STARTER

SHINGLE

FASTENER

LOCATIONS

5 5/8"

PREVAILING

WIND

Figure 22 - Placement and Fastening of RidgeFlex

®

Shingles,

Maintaining the 5

55

⁄88" Exposure

At the end of the ridge, cut a shingle strip, and use the

5

55

⁄88" (143 mm) exposed portion of a RidgeFlex

®

shingle to

create an end cap. Position to maintain the exposure of 5

55

⁄88"

(143 mm), trim to t, and set the cap in asphalt roof cement

conforming to ASTM D4586. Press down rmly to seal.

Should adverse conditions exist (like high winds), the end

cap can also be face-nailed. Place two (2) nails on each

side, 1" (25 mm) back from each end, and 1" (25mm) up

from the sides. Cover the nailheads with a dab of sealant.

(SeeFigure23)

shingle strip, and use the 7

55

⁄88" (194mm) remainder as a starter.

(See Figure 19)

Figure 19 - RidgeFlex

®

Shingle Strip

for Use as a Hip and Ridge Starter Shingle

Apply the starter shingle (with seal-down strip adjacent to

the roof edge) over the bottom corner of the hip or on either

end of the ridge, overhanging the corner or end by ¼"-¾"

(6-19mm), and bending the starter shingle along its centerline

to form into place (ensure shingles are sufciently warm to

avoid cracking).

Fasten with two nails, approximately 3" (76 mm) back

from the leading edge and 1" (25 mm) up from each side.

(SeeFigure20)

5 5/8"

7 5/8"

3"

PREVAILING

WIND

PREVAILING

WIND

STARTER SHINGLE

6 5/8"

END SHINGLE SET

IN MASTIC/SEALANT

Figure 20 - Placement and Fastening of the RidgeFlex

®

Starter Shingle

RidgeFlex

®

Hip and Ridge Shingles: Lay the rst RidgeFlex

®

shingle strip on top of the starter shingle (maintaining the

overhang). Fasten with two nails, 1" (25mm) more than the

designed exposure and 1" (25mm) up from each side so suc-

ceeding hip and ridge shingles conceal nailheads.

To aid installers for determining the exposed portion of a

RidgeFlex

®

shingle, it’s manufactured with a paint line in the

headlap area, opposite the exposed portion. (See Figure 21)

|

MALARKEY LAMINATE SHINGLE INSTALLATION INSTRUCTIONS

9

correctly, fasteners should be covered by the overlying

EZ-Ridge

®

shingles to come, leaving none exposed.

EZ-Ridge

®

Hip and Ridge Shingles: Apply a full-size

EZ-Ridge

®

shingle over the starter and overhang the end of

the ridge by ¼"-¾" (6 -19 mm). Push down on the center of

the shingle and adjust to t the pitch of roof.

Fasten this shingle and those to follow with two (2) nails, one

(1) on each side, ¾" (19 mm) behind the cutout (not on the

exposed part of the shingle) and ½" (13 mm) up from the side.

Continue installing EZ-Ridge

®

shingles across the ridge, over-

lapping each with the side cutouts of the underlying shingle,

and producing a consistent exposure of 8¼" (210 mm). Fasten

in the same manner as the rst. (See Figure 25)

8 1/4"

FASTENER

LOCATIONS

PREVAILING

WIND

STARTER

SHINGLE

Figure 25 - Placement and Fastening of EZ-Ridge

®

Shingles,

Maintaining the 8¼" Exposure

For the last hip and ridge shingle in the run, remove the cutout

portion of an EZ-Ridge

®

shingle and trim the exposure portion

to t or use the exposure portion of the shingle you cut earlier

when creating the starter.

Set this end cap in asphalt roof cement, maintaining the 8¼"

(210mm) exposure. (See Figure 26)

Figure 26 - EZ-Ridge

®

Shingle Cut to Create an End Cap

Should adverse conditions exist (like high winds), the end

cap can also be face-nailed. Place two (2) nails on each side,

1" (25 mm) back from each end, and 1" (25mm) up from the

sides. Cover the nailheads with a dab of sealant.

Note: The end cap can also be ipped around to preserve

the high-prole appearance and give a nished look to the

ridge. Position it to overhang the end of the ridge by ¼"-¾"

(6-19mm). (See Figure 27)

PREVAILING

WIND

END SHINGLE SET

IN MASTIC/SEALANT

5 5/8"

Figure 23 - Installation of RidgeFlex

®

Shingles;

End Cap Set in Mastic

HIGH-PROFILE INSTALLATION (EZ-RIDGE

®

AND

EZ-RIDGE

®

XT HIP AND RIDGE SHINGLES)

Malarkey’s EZ-Ridge

®

is a high-prole hip and ridge shingle

specially designed to accompany laminate and designer shin-

gle applications.

Detail drawings to follow in this section show the installation

of shingles along a roof ridge, but hips are essentially the

same. Instructions for installing along rake edges are at the

end of the section.

Given the added thickness of EZ-Ridge

®

shingles, ensure your

fasteners are long enough to penetrate all layers and at least

¾" (19 mm) into the roof sheathing. Where the roof sheathing

is less than ¾" (19 mm) thick, the fasteners shall penetrate

through the sheathing.

Application begins at the bottom of the hip or from the end of

the ridge opposite the direction of prevailing winds with a hip

and ridge starter shingle.

EZ-Ridge

®

Starter Shingle: To create an EZ-Ridge

®

starter

shingle, cut off the 8¼" (210 mm) exposure portion of the

shingle, and use the remaining 3¼" (83 mm) cutout portion

(with sealant strip) as the starter. (See Figure 24)

Figure 24 - Cutting an EZ-Ridge

®

Shingle

to Make a Hip and Ridge Starter Shingle

Save the exposure portion because it can be used as the end

piece on the opposite end of the ridge.

Note: The longer strip on the end of an EZ-Ridge

®

shingle is

a lm strip that prevents the shingles from sticking together

while in the box they’re packaged in. It is not designed to be

removed.

Place the EZ-Ridge

®

starter shingle ush to the rake at the

peak, and position it so the seal-down strip is adjacent to the

roof edge. Push down on the center of the shingle and adjust

to t the pitch of roof.

Fasten with two (2) nails, one (1) on each side, ¾" (19mm)

behind the cutout and ½" (13 mm) up from the side. If installed

|

MALARKEY LAMINATE SHINGLE INSTALLATION INSTRUCTIONS

10

Make the surface as smooth as possible by replacing missing

shingles and securely nailing all buckles, raised tabs or curled

shingles. Malarkey is not responsible for a potentially objec-

tionable appearance of the new surface from any irregularity in

the substrate caused by remaining roong.

Additional ventilation should be provided, and longer nails will

likely be necessary to penetrate a minimum of ¾" (19 mm)

into the roof deck or completely through plywood or OSB

sheathing.

Installing Class 3 or Class 4 impact resistant shingles over

existing roofs negates their impact resistance and will not

make them eligible for insurance discounts.

FINAL NOTE

These instructions are meant to act as a general guide. If you

have questions about this installation or any Malarkey roong

product, please contact our Technical Services Department

weekdays at (800) 545-1191 or (503) 283-1191, 7:00 am to

5:00 pm Pacic Time. You can also email us at:

malarkey[email protected]. Thank you.

8 1/4"

PREVAILING

WIND

8 1/4"

FASTENER

LOCATIONS

8 1/4"

5 5/8"

PREVAILING

WIND

SET END SHINGLE

IN MASTIC/SEALANT

Figure 27 - Optional Positioning and Fastening of

the EZ-Ridge

®

End Cap

EZ-RIDGE

®

RAKE EDGE INSTALLATION

Instructions are the same as those above with these

exceptions:

1. Always start at the low end of the roof.

2. Have the high-prole, nished ends of EZ-Ridge

®

shin-

gles in the lowest position.

3. Note: Installation with exposed nails may affect the aes-

thetic appeal of EZ-Ridge

®

shingles. (See Figure28)

8 1/4"

5 5/8"

Figure 28 - Installation of EZ-Ridge

®

Shingles on

Rake Edges of the Roof

RE-ROOFING OVER EXISTING ASPHALT SHINGLES

For best performance and appearance, it is recom mended old

roong be completely removed from the deck.

When roong over existing asphalt shingles, it is recom-

mended only 3-tab shingles be overlaid. Roong over lam-

inates creates an irregular surface across each course that

may prevent the newly installed shingles from sealing down

properly, leaving them more susceptible to wind damage.

In some areas, building codes do not require removal of old

roong if: 1) The existing shingles and framing will support the

workers installing the roong, the new roof itself, and required

dead loads; and 2) The old wood deck is sound and able to

provide good anchorage for nails.

Rev. 04/24

P.O. Box 17217

Portland, OR 97217-0217