DO WELL

REPORT

EDITION #1 – 2019

Madewell Do Well Report | 2

LETTER FROM THE CEO

To our community,

Welcome to our first Do Well Report! We know that the fashion industry was not originally built

with sustainability in mind. But we also know that the health of our planet is at stake and that it is

our responsibility to do beer. We have launched several Do Well initiatives over the past few

years, and we are always looking to do more.

A lile over two years ago we decided to go full force and make significant changes—changes that

would allow us to be sustainable throughout our business, from our manufacturers to our HQ to

our retail stores. For us, taking action (and quickly) is the only option. Our planet depends on it.

We also recognize that the well-being of our community is directly tied to us making lasting social

and environmental changes that will have a positive impact on current and future generations who

need it the most. With that in mind, we’ve organized our report into two sections—Planet and

People—in order to highlight the work we’ve done for both.

We’ll be releasing our Do Well Reports annually to keep you informed on new initiatives and

products, and how we’re improving our sustainability practices across our operations. We are

proud of the work we’ve done so far, and we hope you are too.

All my best,

LIBBY WADLE, CEO

LETTER FROM THE CEO

Madewell Do Well Report | 3

OUR APPROACH

Now more than ever, we recognize the need to act with urgency to address the climate crisis

and ensure those in our community are protected. That’s why we set long-term commitments to

further our sustainable practices across all areas of our business.

Our sustainability initiatives are led by the Corporate Social Responsibility team, which reports

to our Sourcing, Supply Chain and Sustainability department. Our senior leadership is heavily

involved in our sustainability eorts through our Do Well Commiee, and we work to align on

strategic decisions for all sustainability activities and updates.

In 2015 the United Nations agreed on a new development path—the 2030 Agenda for Sustainable

Development, a groundbreaking plan of action for people, planet and prosperity. Implementing

this plan requires partnerships and collaboration, which is why we’ve aligned our sustainability

strategy with the United Nations’ Sustainable Development Goals (SDGs). The 17 goals and

169 targets outlined by the UN provide a blueprint for countries and organizations around the

globe to work toward creating a healthier world. In order to stimulate action, we mapped

our sustainability strategy against the SDGs and identified seven SDGs that align with our

commitments and values, which are:

We’ve used the above goals as guidelines in shaping our sustainability strategy, our major

milestones and ongoing initiatives, and our social and environmental impacts.

Madewell Do Well Report | 4

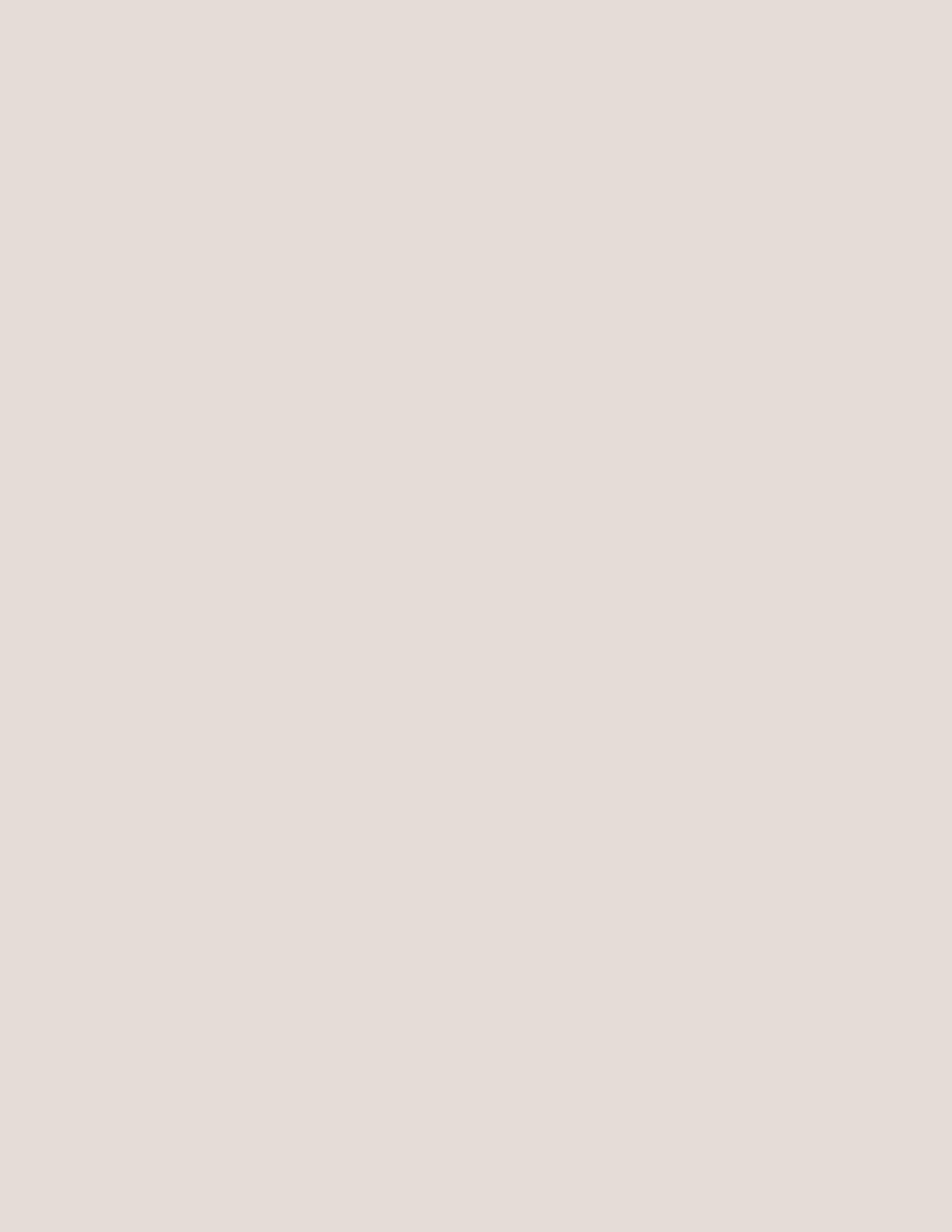

BY 2025:

BY 2030:

100% OF THE

KEY FIBERS

USED IN OUR

MATERIALS

WILL BE

SUSTAINABLY

SOURCED

AND FREE

OF VIRGIN

PLASTIC

OUR ENTIRE

OPERATIONS

WILL BE

CARBON

NEUTRAL

100% OF OUR

PACKAGING

WILL BE

SUSTAINABLY

SOURCED

AND FREE

OF VIRGIN

PLASTIC

MORE THAN

90% OF OUR

DENIM WILL BE

FAIR TRADE

CERTIFIED

™

OUR GOALS

We know that sustainability is a journey, and we are commied to continue improving our

practices. In the coming years we will be partnering with our supply chain to develop strategies

and goals to mitigate water risk, contribute to water basin conservation and reduce Scope 3

carbon emissions (according to the World Resources Institute’s Greenhouse Gas Protocol).

Edition #1 – 2019

Madewell Do Well Report | 5

PLANET

THIS SECTION COVERS THE

IMPACT WE HAVE ON THE

PLANET—FROM THE MATERIALS

WE SOURCE, TO OUR

ENVIRONMENTAL FOOTPRINT,

TO OUR SUPPLY CHAIN. WE’RE

IMPLEMENTING CHANGES AS

QUICKLY AS POSSIBLE ACROSS

OUR OPERATIONS TO ENSURE

THAT WE’RE EFFECTIVELY

ADDRESSING THE CLIMATE

CRISIS AT EVERY STEP OF OUR

PRODUCTION.

Madewell Do Well Report | 6

CIRCULARITY

Creating a circular life cycle solution for our denim is a priority for us. The fashion industry

tends to be resource intensive and the stats are staggering: Clothing production has doubled

within the last 15 years with less than one percent of the material recycled into new garments.

And every second, the equivalent of one garbage truck of textiles is burned or sent to landfills.

QUALITY

We’re commied to extending the life cycle of our products by

designing durable pieces crafted with quality materials. (The

Sustainable Apparel Coalition lists durability as having a “very high”

relevance to overall environmental performance.) To that end, we’ll

be creating programs to make your jeans last longer than ever—and to

keep denim out of landfills.

ECO-FRIENDLY GARMENT CARE

Frequently laundering denim (and clothing in general) isn’t great

for the environment. That’s why we’ve designed our jeans with

instructions printed in the inner pocket that teach customers how

to be more eco-conscious when caring for their jeans. Our garment

labels provide helpful tips like washing with cold water, skipping

the dryer to save energy and ways to keep jeans as fresh as possible

before having to wash them. (Plus, proper care will make denim last

longer!) You can also read about best practices for greener laundry

days in this blog post.

REUSE AND RENEW

In October 2019 we launched our partnership with thredUP to become

the first retail brand to test out an in-store resale platform. The

Madewell Archive is a carefully curated selection of our favorite pre-

owned denim styles—hand-selected, washed and refurbished—that

are available for customers to purchase at select stores. This program

allows our customers to get rid of their worn-in jeans responsibly and

to buy an upcycled style (rather than buying new).

Madewell Do Well Report | 7

We also partnered with Rent the Runway, a membership-based clothing

rental company, so customers can rent Madewell clothes instead of

having to buy new. This means that a single item might be worn by

multiple customers, reducing the unnecessary purchase of items that

are only worn a few times.

Through these partnerships that encourage the reuse of garments, in

2019 we were able to save:

1,674,607 LITERS

OF WATER—

this is approximately

the same amount of

water that 1,475 U.S.

households use each

day.

28,273 KG OF

CO

2

—

these are emissions

equivalent to charging

3,605,719 smartphones.

310,048 M J O F

ENERGY

(or 86,124 kWh)—

this is equivalent to

powering about 2,800

households in the U.S.

for a day.

COTTON’S BLUE JEANS GO GREEN™ PROGRAM

We know that some worn-out jeans will end up in conditions beyond

repair. Luckily, we have a solution for what to do with those well-loved

styles. Through our partnership with Coon’s Blue Jeans Go Green™

program, we take worn-out denim and turn it into housing insulation

for communities in need, which keeps homes warmer in the winter and

cooler in the summer. As of September 2020, we’ve recycled more than

1,058,672 pairs of jeans, which has diverted 529 tons of total waste and

helped to insulate 1,412 homes (or 2,117,344 square feet).

Madewell Do Well Report | 8

WO OL

We’re commied to sourcing wool that is

organic, recycled or certified to the Textile

Exchange’s Responsible Wool Standard (RWS),

or to equivalent standards. We are currently

in the process of certifying our supply

chain and converting our products to RWS

or equivalent certifications. We’re actively

working to drive the use of RWS wool and

we’re excited to bring certified wool products

to you this year!

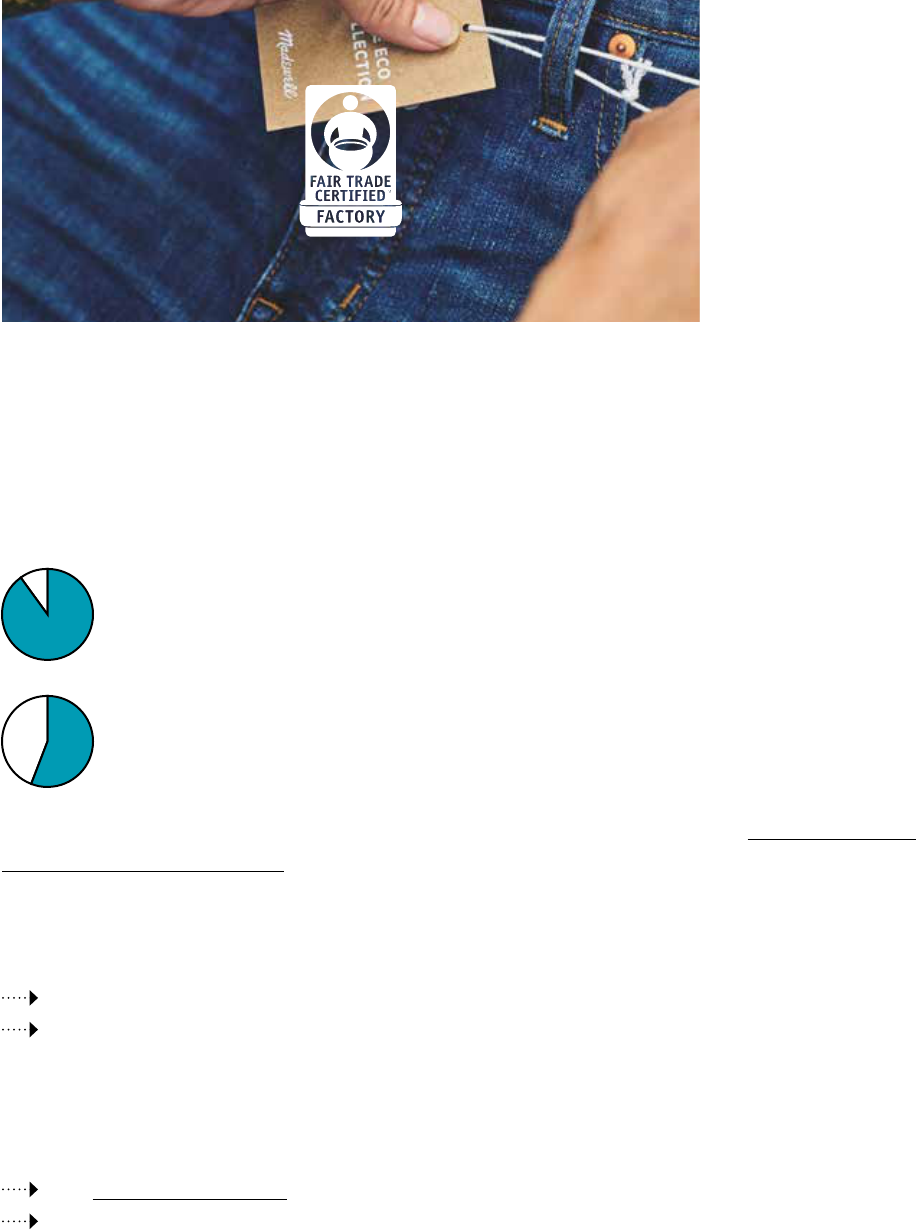

C EL LU LOSI CS

Currently, 25% of our

cellulosic fibers—Lenzing™

Ecovero™, Refibra™ and

Tencel™ Lyocell—are

made from responsibly and

sustainably sourced trees.

SYNTHETICS

Currently, 4% of our synthetic

fibers are made from recycled

polyester and recycled nylon.

COTTON

Currently, 44% of our

coon is organic, recycled

or sourced through Beer

Coon Initiative (BCI), which

trains farmers in more

environmentally, socially and

economically sustainable

farming practices.

LEATHER

Currently, 51% of our leather

is recycled or sourced from

tanneries audited against the

Leather Working Group (LWG)

standard, which evaluates the

compliance and environmental

performance of tanners

and promotes sustainable

environmental practices within

the leather industry.

OUR MATERIALS

On average, about two-thirds of the environmental impact of a fashion brand—in terms of

water, energy and land use—happens at the raw materials stage. Over the past two years, we’ve

transitioned into using sustainable raw material sources for many of our products, which we call

our Do Well Materials. We’re focused on our five key fibers, which combined represent over 90%

of our material consumption by total fiber volume. They are:

Madewell Do Well Report | 9

TRUST AND VERIFICATION

As we source more sustainable raw materials for our products, we will continue to verify the

authenticity of our sustainability claims. For this, we rely on trusted third-party certifying

bodies.

OUR MATERIAL VERIFICATION PARTNERS INCLUDE:

For Organic Content: Global Organic Textile Standard (GOTS), Organic Content Standard

(OCS) or the U.S. Department of Agriculture (USDA Organic)

For Recycled Content: Global Recycled Standard (GRS) or Recycled Content Standard (RCS)

For Coon sourced through the Beer Coon Initiative (BCI): We use BCI’s mass balance

system to track our annual consumption of Beer Coon

For Responsible Wool: Responsible Wool Standard (RWS)

For Cellulosic Fibers: Forest Stewardship Council (FSC) Certification, Programme for

the Endorsement of Forest Certification (PEFC) or sourced from suppliers approved by

Canopy, an organization working to eliminate the use of Ancient and Endangered Forests in

viscose and other cellulosic fabrics

For Leather: Tanneries certified by the Leather Working Group (LWG), an organization that

works to promote sustainable environmental practices in the leather industry

OUR SOURCING POLICIES

We are commied to a standard of excellence in every aspect of our business, including legal,

ethical and responsible conduct, and responsible sourcing. We uphold such principles and

practices by seing clear expectations with our suppliers. Our full set of responsible sourcing

policies can be found here and include, among other topics, the prohibition of sandblasting and

coon from Uzbekistan. To ensure accountability and compliance with our sourcing policy, we

also require that suppliers have the ability to trace back their materials to the country of origin

along with verifiable documentation.

BY SPRING 2020,

60% of our collection

used at least one major

sustainable Do Well Material.

IN 2019,

almost 35% of our fibers by

total fiber volume that we

procured were sourced from

Do Well Materials.

BY 2025,

100% of the key fibers used

in our materials will be

sustainably sourced and free

of non-recycled plastics.

Madewell Do Well Report | 10

3,470 MT CO

2

e across all Madewell operations

1.01 MT CO

2

e per employee

MT CO

2

e per retail square footage in 2018: .007876

MT CO

2

e per retail square footage in 2019: .007335

Decrease of CO

2

e per sf 6.8% in 2019

OPERATIONS

Last year, we focused on measuring and understanding the environmental impact of our own

operations. As our company continues to grow, so too does our operational footprint. That’s

why it’s important for us to manage and reduce our energy usage. By 2030, our goal is to achieve

carbon neutrality in our operations (Scope 1 and Scope 2 emissions for our owned and operated

facilities, according to the World Resources Institute’s Greenhouse Gas Protocol).

OUR FLEET INCLUDES:

One corporate oice in Long Island City, NY;

59,626 square feet

Two distribution centers:

one in Virginia, the other in North Carolina;

both total 710,000 square feet

OUR CARBON FOOTPRINT

The following figures cover the greenhouse gas emissions of the electricity and natural gas usage

from our retail locations, corporate oice and distribution centers. Our energy usage data is

continuously captured and tracked by a third party.

OUR RETAIL LOCATIONS

ACROSS THE U.S.:

In 2018: 129 stores; total 440,526 square feet

In 2019: 140 stores; total 473,021 square feet

(we increased our overall retail store square

footage by 7%)

Madewell Do Well Report | 11

OFFSETTING OUR CARBON FOOTPRINT

In an eort to help oset our carbon footprint, we partnered with the National Forest

Foundation (NFF) in 2019 to fund the planting of 15,315 ponderosa pine seedlings to aid in

reforesting the Boise National Forest, which experienced a massive fire in 2016. Once these

seedlings grow, they will sequester approximately 7,500 tons of CO

2

. Click here to learn

more about this program.

In addition, here are other areas we’re working on in order to become a more energy

eicient business:

LED LIGHTS

We’re using energy-eicient LED lights in all stores, which last longer and use up to 80% less

energy than incandescent bulbs.

PAPER IMPACT

• We’re planting enough trees to oset the total usage of printing paper that we use in

our HQ and stores, in partnership with our paper supplier FlexPrint and the nonprofit

organization Trees for the Future.

• We’re removing packing slips from all orders.

• We oer paperless receipts for store customers, which has reduced the average monthly

usage of paper receipts in our stores by 37% in comparison to 2018.

ENERGY USAGE

We reduced our average monthly energy usage in our corporate oice by 40% in comparison

to last year.

PACKAGING

• Our shopping bags are made of 80% post-consumer recycled content. Later this year, we’ll

ensure that all our bags are certified by the Forest Stewardship Council.

• We’ve engineered our mailers to be usable for two deliveries so returns and exchanges can

be sent back in the original packaging. Our mailers are currently made from 30% recycled

content; in 2021, our mailers will be made from 50% recycled content.

• We’re working to incorporate recycled content into our polybags, as well as continuing to

research plastic packaging alternatives and innovations.

• BY 2025, 100% OF OUR PACKAGING WILL BE SUSTAINABLY SOURCED AND

FREE OF VIRGIN PLASTIC.

TRANSPORTATION

We partnered with UPS’s Carbon Neutral Shipping program, which supports environmental

projects that oset the emissions of shipment transport via online orders. This means that

Madewell Do Well Report | 12

for every ton of CO

2

emied by a package shipment, an equivalent amount of CO

2

is

saved by a verified emission reduction project somewhere else in the world. Through

this program with UPS, we have oset 6,026 metric tons of emissions in 2019 (equivalent

to taking 1,300+ cars o the road for a year) and funded eorts to conserve forestland

in Canada, capture biogas from a tapioca starch manufacturer in Thailand and capture

methane from a Georgia landfill. (These projects have been verified and certified by a

third party in accordance with The CarbonNeutral Protocol.)

OUR SUPPLY CHAIN IMPACT

We have a responsibility to ensure that our supply chains are taking steps to reduce the impact

of our products.

HIGG FEM

In 2019, we developed a long-term plan to use the Higg Facility Environmental Module (FEM)—a

sustainability assessment tool that standardizes how facilities measure and evaluate their

environmental performance—to understand the environmental impacts of our supply chain and

to find opportunities to improve environmental performance. We rolled out the adoption of

the Higg FEM to our strategic vendors and additionally to strategic mills and trim suppliers. This

eort resulted in 147 vendor factories, mills and trim suppliers reported to the Higg Index FEM,

which represents 99% of our targeted facilities in our plan, and we will be leveraging the data

from the Higg FEM to reduce the environmental impact in our supply chain.

BEST PRACTICES IN CHEMICAL MANAGEMENT

In late 2019, we started working with Bluesign, an organization that developed systems and

standards to address chemical inputs, energy consumption, water use, wastewater, hazardous

waste and air emissions. Bluesign addresses the types of chemicals and how those chemicals

are used at the mills, dyers and finishers. We’re looking forward to continuing our work

together and learning how to improve our eorts. We’ll be sharing our progress in our 2021

sustainability report.

To manage chemical use in our global supply chain and products, we’ve adopted AFIRM’s

Restricted Substance List (RSL), which is designed to reduce the total usage and impact of

harmful substances in the apparel and footwear supply chain and helps us make sure that

harmful substances are not present in our products. We require our vendors to comply with

the AFIRM RSL and we work with third-party organizations to test our products and monitor

compliance with our chemical restrictions. You can access AFIRM’s Restricted Substances List

here, available on our Social Responsibility practices and policies page.

Madewell Do Well Report | 13

PEOPLE

THE PEOPLE SECTION

COVERS THE PEOPLE IN OUR

COMMUNITY—FROM OUR

SUPPLIERS, TO OUR HQ AND OUR

STORES. TO BE A SUSTAINABLE

COMPANY, WE HAVE TO ENSURE

THAT EVERYONE INVOLVED IN

THE MADEWELL COMMUNITY

IS TREATED WELL AND WITH

RESPECT. THIS DATA FROM THE

2019 FISCAL YEAR SHOWS OUR

COMMITMENT TO CREATING

AN INCLUSIVE ENVIRONMENT

AND GIVING BACK TO THE

COMMUNITY.

Madewell Do Well Report | 14

We’ve launched three new clothing categories: Denim, Wovens and Sweaters.

We oer 124 Fair Trade Certified™ styles in our Fall 2020 collection, up from the 16 styles in

our Spring 2019 collection when we launched our fair trade program in January.

• Denim: 81

• Wovens: 35

• Sweaters: 8

We added 57 new styles to our Fall 2020 collection.

56% of our denim is now Fair Trade Certified™, up from 29% in Spring 2020.

FAIR TRADE

In early 2018, we began partnering with Fair Trade USA when we started the certification process

of Saitex, our Vietnam-based factory. This partnership allows us to foster an environment

where people are empowered to generate and sustain lasting impact at work, at home and in

their communities. For each certified product, we pay a premium that goes to a community

development fund run by the workers. Currently it takes an estimated eight to 12 months for a

factory to aain a Fair Trade USA certification.

The full requirements for earning Fair Trade certification can be found at the Factory Standard

for Apparel and Home Goods.

As of Fall 2020, our collection is manufactured at a total of six Fair Trade Certified™ factories,

which is up by five factories from when we launched last year.

BY 2025, MORE THAN 90% OF OUR DENIM WILL BE

FAIR TRADE CERTIFIED™

CURRENTLY, 56% OF OUR DENIM COLLECTION IS

FAIR TRADE CERTIFIED™

Madewell Do Well Report | 15

Training of more than 800 farmers on sustainable agricultural practices.

Cultivation on approximately 1,500 hectares of farmland of Beer Coon—that’s equivalent

to roughly 2,800 football fields.

The demand for approximately 1.3 million kilograms of Beer Coon to be produced—

that’s how much coon it takes to make over 2 million pairs of jeans!

GET TO KNOW: BETTER COTTON INITIATIVE

The Beer Coon Initiative (BCI) is a nonprofit organization that promotes continuous

improvement for coon farmers across the globe. BCI partners with brands—like us!—to get

funding for farmer trainings and certification so they can learn and implement more sustainable

farming techniques. Training topics include integrated pest management (that keeps the good

bugs and removes the bad), organic fertilizer options and safety training for pickers and owners

(e.g., chemical safety and protective equipment). Implementing these sustainable practices leads

to reduced resource costs and increased yields, resulting in economic benefits for the farmers.

Because we source more coon than any other material, it’s paramount to our sustainability

mission to find a way to improve the way coon is grown. Partnering with BCI was an easy

decision for us. We first started working with BCI in 2016, and our commitment has grown since

then. Our contributions to the program in 2019 alone have led to an additional 1.3 million Beer

Coon Claim Units (aka BCCUs, which equate to a kilogram of Beer Coon) entering the global

supply chain.

Our sourcing of Beer Coon in 2019 enabled:

Madewell Do Well Report | 16

We prioritize diversity, inclusion and the overall well-being of our associates. In 2019, the J.Crew

Group (Madewell is a subsidiary company within the J.Crew Group) scored 100% on the Human

Rights Campaign Corporate Equality Index, earning the designation of Best Place to Work for

LGBTQ Equality. We’re commied to upholding this score for years to come.

OUR TEAM

AS OF 2019, OUR COMPANY HAS:

690 FULL-TIME

AND

2,736 PART-TIME

PEOPLE

Madewell Do Well Report | 17

DIVERSITY, EQUITY AND INCLUSION

We stand with the Black community, and we pledge to be an actively antiracist company. Here

are our commitments:

WE WILL LISTEN TO LEARN

This will include community forums for all associates, available in group and individual formats,

to encourage conversations and share experiences around racial injustice as well as gather

feedback. Our goal is to beer equip our teams with the right tools and destigmatize these

crucial conversations.

WE WILL EDUCATE OURSELVES AND OTHERS

To create understanding and awareness around important issues in our workplace, we will

build on existing programs like our diversity dialogue training and mandatory unconscious bias

workshops for our leadership team.

WE WILL BUILD OUR TALENT PIPELINE

This will include a partnership with Jopwell, a career advancement platform for Black, Latinx

and Native American students and professionals. We will also work with colleges, universities

and organizations that promote racial and socioeconomic diversity to invest in how we aract,

retain and promote talent from underrepresented and minority backgrounds. We’ve also

partnered with America Needs You, an organization that fights for economic mobility for

OUR COMMUNITY

Community is at the core of Madewell and we recognize that our sustainability eorts have to

include a commitment to fostering a diverse, inclusive environment. We’ve made a promise to

beer serve our Black and local communities through ongoing donation and volunteer programs

and through initiatives like our Hometown Heroes program. These commitments act as the

groundwork for a plan that will continue to grow and evolve.

Madewell Do Well Report | 18

ambitious low-income, first-generation college students. Our recruiting department supports

any and all students who want to further their career development by hosting a dedicated

virtual Career Day for them.

WE WILL SUPPORT COMMUNITY ENGAGEMENT

This will include creating associate interest groups for individuals to come together around

common interests and continuing our internal donations and employee matching programs to

encourage giving back to organizations that we believe in.

WE WILL AMPLIFY BLACK VOICES

We remain commied to featuring Black Indigenous People of Color in our content and to

ensuring diversity both in front of and behind the camera. We will continue to use our platform

to amplify the voices of Black Indigenous People of Color in the stories we tell.

WE WILL SUPPORT BLACK-OWNED BUSINESSES

As a long-standing supporter of small businesses and creatives and knowing the

disproportionate impact that COVID-19 has had on Black-owned businesses specifically, we

are commiing today to increasing their representation as part of our Labels We Love and

Hometown Heroes programs.

WE WILL ADVOCATE FOR CHANGE

To further our partnership with the ACLU, we have pledged to donate at least $750,000, funded

by sales of our entire Vote collection, to support their mission to ensure equality in our country

and combat issues that disproportionately aect Black Americans, like voting rights.

WE WILL VOTE

We believe in the power of voting to enact change so will be closing all stores, our distribution

center and our corporate oices on November 3

rd

to allow our teams ample time to vote.

OPEN TO ALL

We’re commied to the mission of Open To All, a nondiscrimination campaign that works

with businesses and companies taking a stand against discrimination. We are pledging to:

Maintain a welcoming and safe environment for people—including employees,

visitors, customers, vendors and clients—regardless of race, ethnicity, national origin,

sex, sexual orientation, gender identity and expression, immigration status, religion or

disability.

Not discriminate against any individuals or deny them goods or services based on

any of these characteristics and to provide all goods and services to everyone on the

same terms.

Madewell Do Well Report | 19

CAUSES WE BELIEVE IN

Throughout the year, we team up with organizations across the country that are aligned with our

values and we find ways to support their missions, whether it’s through monetary donations,

collaborating with them on exclusive collections, hosting events or volunteering. In addition

to oering our full-time associates paid volunteer time o, we encourage them to choose any

nonprofits they wish to personally support through several give-back programs including a

donation-match opportunity called You Give, We Give. Here are a few ways we support the

causes we care about:

GIVE BACK PARTNERS

We collaborate with organizations we believe in and that align with our

values.

AMERICAN CIVIL LIBERTIES UNION

In 2020, we partnered with the American Civil Liberties Union to

support its mission in maintaining and advancing civil liberties,

which includes protecting the fundamental right to vote for all

who are eligible. Along with providing educational resources to

both our internal and customer communities, we created a Vote

collection with 100% of the proceeds going back to the ACLU.

NO KID HUNGRY

We’re proud to support No Kid Hungry, a campaign that is

commied to feeding kids in need during the pandemic crisis

and beyond. Since March, we’ve helped provide up to one million

meals to kids in need. Learn more at NoKidHungry.org/OneDollar.

ADDITIONAL PARTNERS

In 2019, we partnered with charity: water, Girls Inc. and the

Human Rights Campaign. With the support of our customers, we

were able to donate a total of $486,000 back to these nonprofit

partners.

HOMETOWN HEROES COMMUNITY & COLLECTIVE

Our Hometown Heroes Community program was launched in 2010 to

support local communities by giving artists and makers the opportunity

to sell their goods in Madewell stores. Since its launch 10 years ago, the

Hometown Heroes Community has become a foundation of Madewell—

we now host thousands of Hometown Heroes events in stores each year.

In 2019, Madewell teamed up with nonprofit Nest to launch the next

iteration of the Hometown Heroes program, called the Hometown

Heroes Collective. Nest is a vital force in the maker community—the

Madewell Do Well Report | 20

organization works to build a new handworker economy to increase

global workforce inclusivity, improve the well-being of women beyond

factories and preserve important cultural traditions around the world.

In partnership with Nest, the Collective supports four classes of makers

per year, celebrating their communities and American craftsmanship.

We oer our makers monetary grants, expert mentorship, networking

opportunities, marketing support and the ability to sell their goods on

Madewell.com. Since the launch of the Hometown Heroes Collective,

we’ve featured six classes made up of 42 talented makers and we’ve

provided them meaningful support to help them grow their businesses.

Through our Hometown Heroes Collective program, we’re commied

to amplifying our values around diversity and inclusion. With that, we’ll

ensure that each class consists of at least 40% BIPOC makers, 20% of

those who identify as Black.

COMMUNITY GIVE BACK EVENTS

We encourage our stores to host events where a portion of the

proceeds are donated to local charitable organizations. This allows

our associates to choose the initiatives that best resonate with their

community. In 2019, we hosted 170 charitable store events.

YOU GIVE, WE GIVE

We know our associates have their own causes that they’re passionate

about supporting. With the J.Crew “You Give, We Give” matching fund,

we’ve been able to set up individual support of causes through cash

donations made on our associates’ behalf from J.Crew. We encourage full-

time associates who have contributed their own money and/or volunteer

time to a nonprofit to submit a request for a cash or time donation match

on their behalf from J.Crew to the charity of their choice.

GOOD360

We support Good360, a 501(c)(3) nonprofit whose mission is to transform

lives by providing hope, dignity and a sense of renewed possibility to

individuals, families and communities impacted by disasters or other

challenging life circumstances. We partnered with Good360.org on our 2:1

disaster match which funded disaster recovery relief and the long-term

rebuilding of resilient communities.

Madewell Do Well Report | 21

SUPPLY CHAIN:

LABOR PRACTICES & SOCIAL IMPACT

At Madewell we believe that fair and decent working conditions, the freedom of opinion

and expression, and an adequate standard of living are basic human rights. We have direct

relationships with 75 factories (Tier 1, garment manufacturing) from 16 countries. We have various

processes and policies in place to ensure that our vendors are reliable partners who strictly

adhere to social and labor law.

We strictly prohibit the use of any form of forced labor or human rights abuses and continue

to work closely with international and regional stakeholder groups to stay abreast of potential

issues that could lead to increased vulnerability of workers in our global supply chain. Our

Vendor Code of Conduct outlines our expectations for all the factories, subcontractors,

suppliers and others who are ailiated with the production of our goods. These standards

are based on the International Labor Organization (ILO) conventions and other internationally

recognized labor rights groups.

For more information, you can read our Code of Ethics & Business Conduct here and our Social

Responsibility Approach here.

Madewell Do Well Report | 22

0

0%

Factory has one

or more Zero

Tolerance issues

and/or has failed

to correct major

safety, health

or labor related

issues. Our team

will investigate

the issues and

depending on

severity we may

halt production

or exit the

facility.

Next Audit:

0–3 months

3

4%

Facility has safety

or labor related

issues that may

require change

in systems,

procedures or

policies. Our

team will work

closely with the

facility to provide

support or

training.

Next Audit:

3–6 months

42

56%

Facility has

minor/moderate

issues. Corrective

Actions are

required.

Next Audit:

6–9 months

30

40%

Facility meets our

standards.

Next Audit:

12 months

Number of

factories:

Percent of

factories:

Compliance

Status:

REDORANGEYELLOWGREEN

THIRD-PARTY AUDITING

While it’s relatively simple to communicate our expectations to our vendors, it is more

complicated to verify compliance throughout all areas of our supply chain. That’s why we

also monitor compliance with our standards and policies on a regular basis by partnering with

third-party organizations to conduct both semi-announced and fully unannounced inspections

of our manufacturing facilities. Through these external audits we are able to identify any

potential issues and their root causes and work with our vendors on building capacity for

positive change.

To date, we work directly with 75 factories, all of which are inspected based on their

compliance performance and are rated based on the compliance status of the factory.

Madewell Do Well Report | 23

For questions or more information on our Do Well Report, contact us at DoWel[email protected] or

visit our Do Well hub.

A LIST OF OUR CURRENT PARTNERSHIPS