Oregon Administrative Rules

Chapter 437

Division 4

Agriculture

Administrative

Order 2-2023

ii

The Oregon Department of Consumer and Business Services adopted these rules pursuant to ORS

654.025(2).

The Secretary of State designated OAR Chapter 437 as the “Oregon Occupational Safety and Health

Code.” Six general subject areas within this code are designated as “Divisions.”

• Division 1 General Administrative Rules

• Division 2 General Occupational Safety and Health Rules

• Division 3 Construction

• Division 4 Agriculture

• Division 5 Maritime Activities

• Division 7 Forest Activities

• Oregon Revised Statutes (ORS) 654 The Oregon Safe Employment Act (OSEAct)

Oregon-initiated rules in this division of the Oregon Occupational Safety and Health Code are

numbered in a uniform system developed by the Secretary of State. This system does not number

the rules in sequence (001, 002, 003, etc.). Omitted numbers may be assigned to new rules at the

time of their adoption.

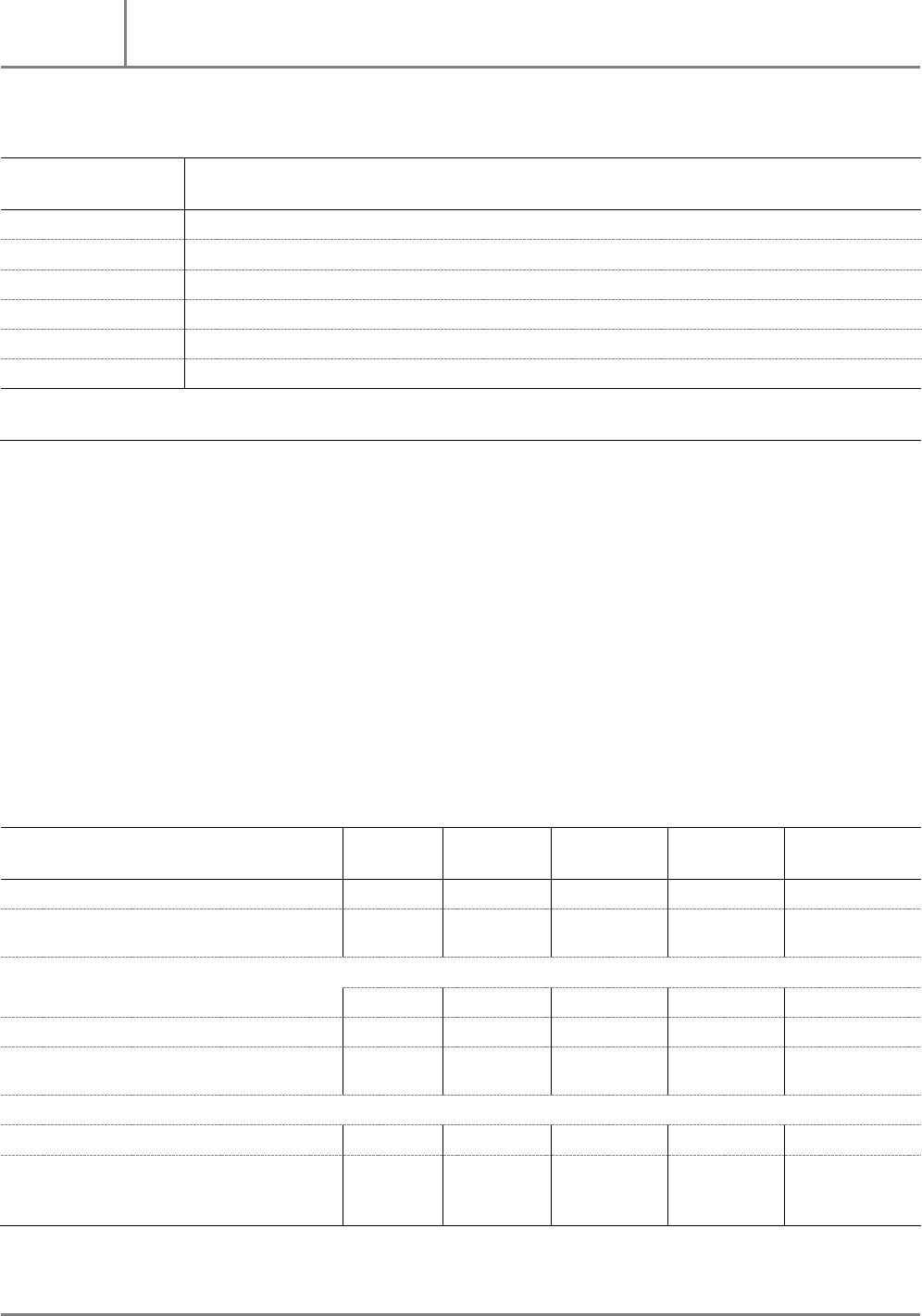

Oregon-initiated rules are arranged in the following Basic Codification Structure adopted by the

Secretary of State for Oregon Administrative Rules (OAR):

Chapter Division Rule Section Subsection Paragraphs

437 004 0150 (1) (a) (A)(i)(I)

The majority of Oregon OSHA rules are adopted by reference from the Code of Federal Regulations

(CFR), and are arranged in the following basic federal numbering system:

Chapter Division Part Subpart Section Paragraphs

(Subdivision)

437 004 1928 M .1027 (a)(1)(i)(A)(1)

The terms “subdivision” and “subpart” are synonymous within OAR 437, Oregon Occupational Safety

and Health Code.

To obtain an order form or copies of these codes, address:

Department of Consumer & Business Services

Oregon Occupational Safety & Health Division (Oregon OSHA)

350 Winter St. NE

Salem, OR 97301-3882

Or call the Oregon OSHA Resource Library at 503-378-3272

The rules referenced in this division are available for viewing in the Office of the Secretary of State,

Oregon State Archives Building, Salem, Oregon, or the Central Office, Oregon Occupational Safety

and Health Division of the Department of Consumer and Business Services, 350 Winter St. NE,

Salem, Oregon, and on our web site at osha.oregon.gov.

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

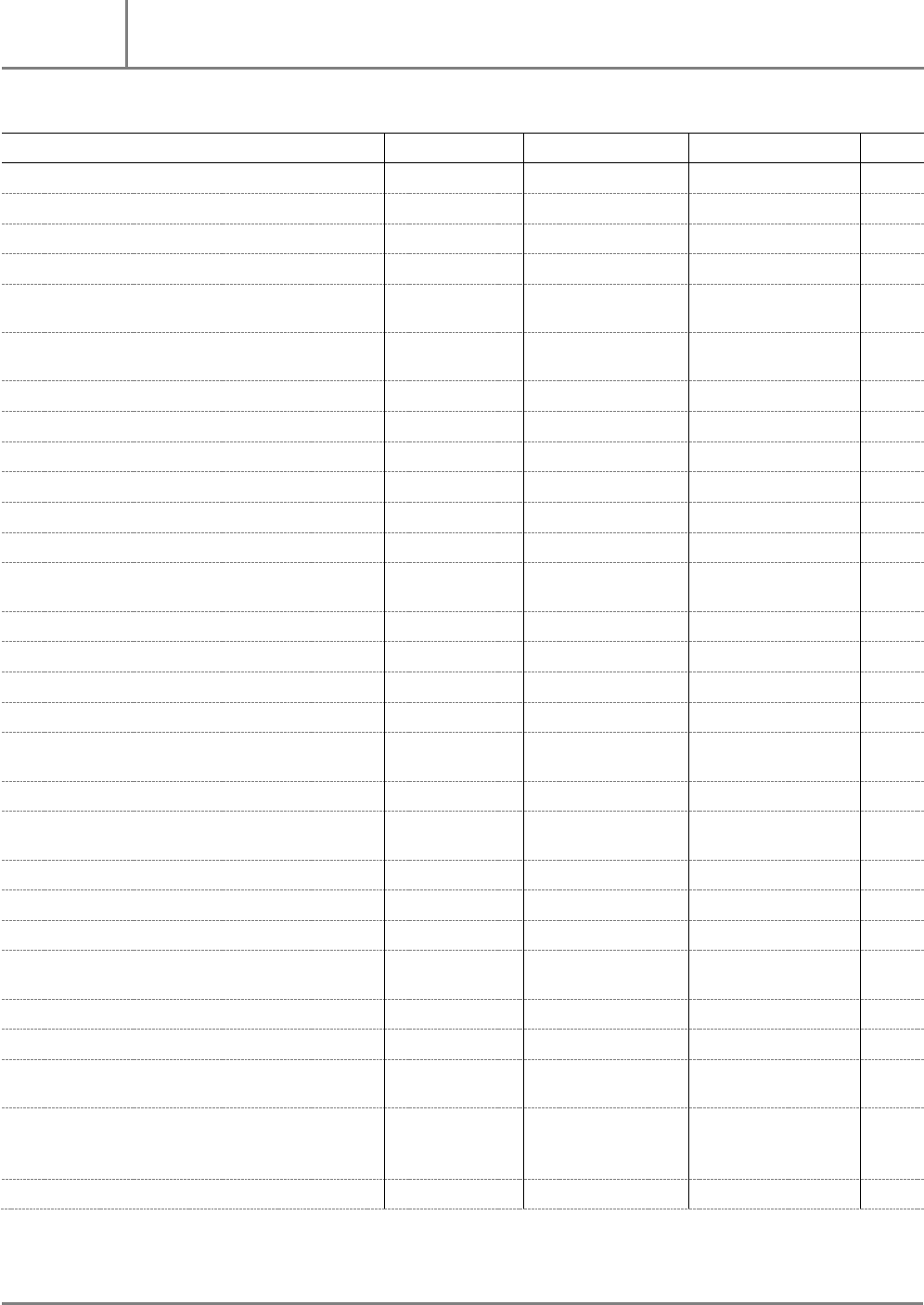

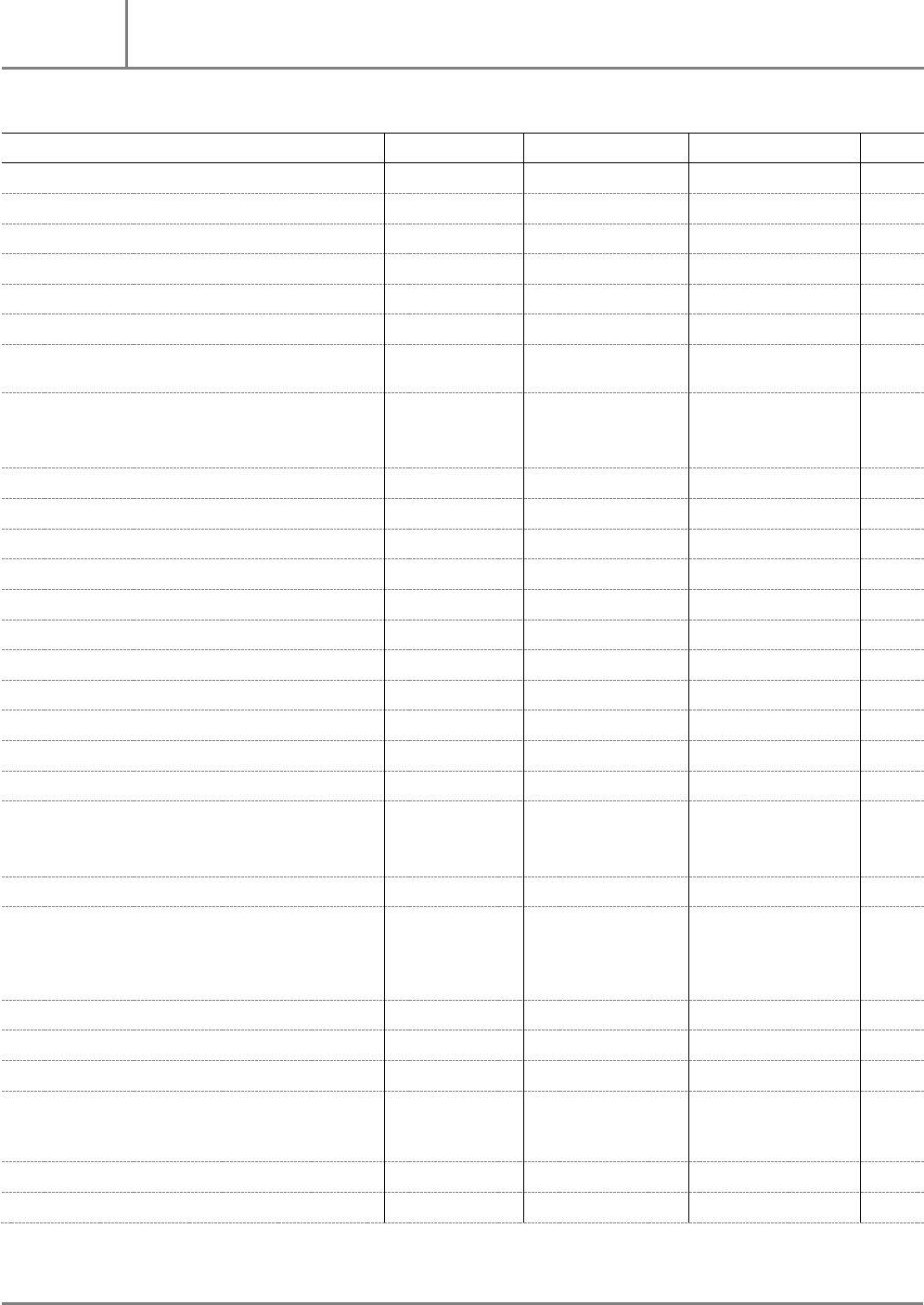

Table of contents

Div. 4 - 3

Table of contents

Table of Contents for Division 4

Historical Notes for Division 4 ............................................................................................. 665

Subdivision A, General Subjects

437-004-0001 Application ........................................................................................... A-1

437-004-0002 Scope ................................................................................................... A-1

437-004-0003 Exclusive Coverage ............................................................................. A-2

437-004-0005 Access to Employee Exposure and Medical Records .......................... A-2

437-004-0099 General Standards ............................................................................... A-3

Subdivision B, Definitions

437-004-0100 Universal Definitions ............................................................................ B-1

437-004-0150 Standards Organizations ..................................................................... B-7

Subdivision C, Safety Committees

437-004-0240 Safety Orientation for Seasonal Workers ............................................. C-1

437-004-0251 Safety Committees and Safety Meetings ............................................. C-2

Subdivision D, Work Surfaces

437-004-0310 Working Surfaces ................................................................................. D-1

437-004-0320 Guarding Floor and Wall Openings and Holes ..................................... D-2

437-004-0330 Fixed Industrial Stairs .......................................................................... D-8

437-004-0340 Portable Ladders ................................................................................ D-11

437-004-0350 Orchard Ladders ................................................................................ D-17

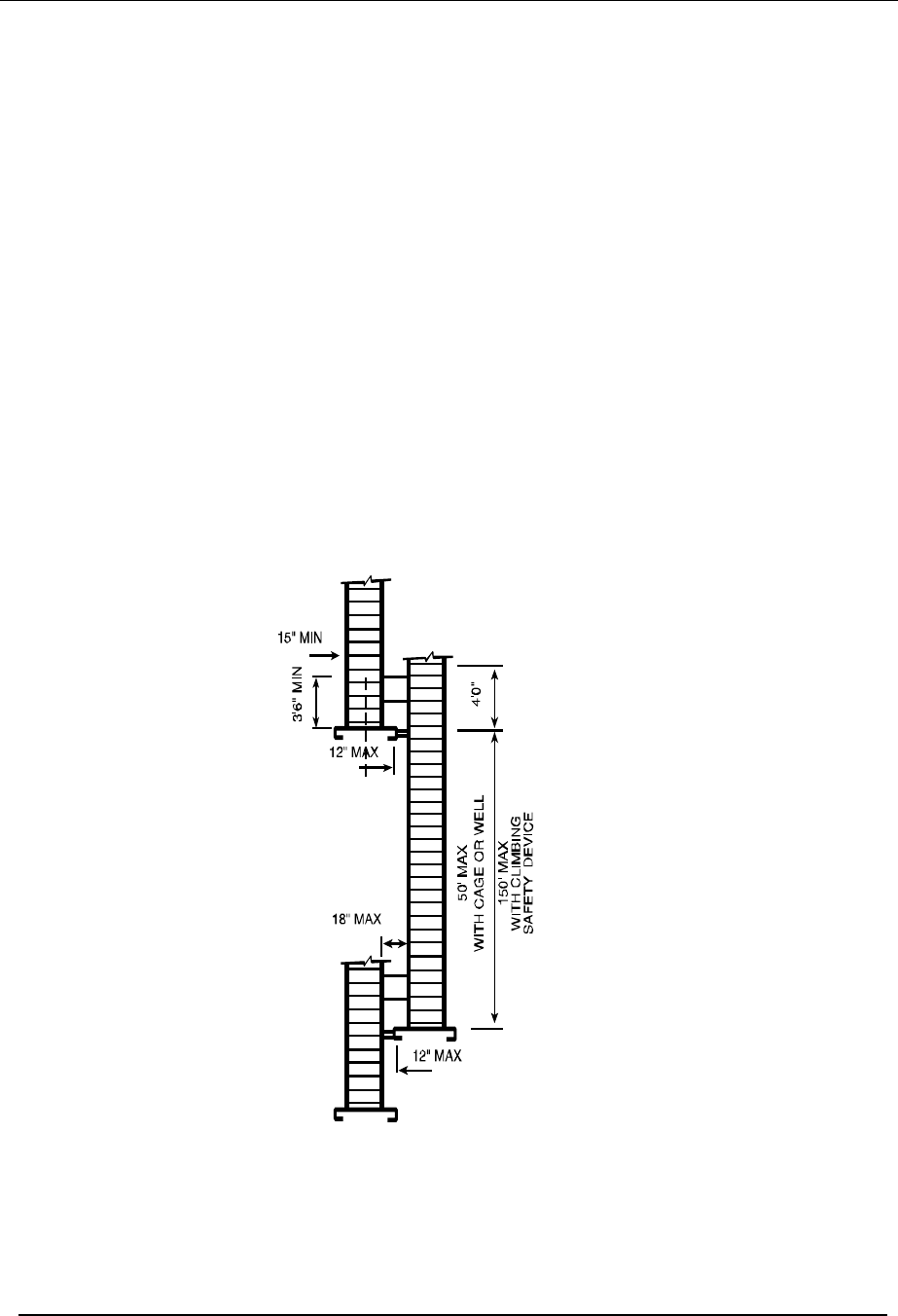

437-004-0360 Fixed Ladders .................................................................................... D-18

437-004-0370 Scaffolding ......................................................................................... D-29

437-004-0380 Manually Propelled Mobile Ladder Stands and Scaffolds (Towers) ... D-39

437-004-0390 Other Working Surfaces ..................................................................... D-40

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

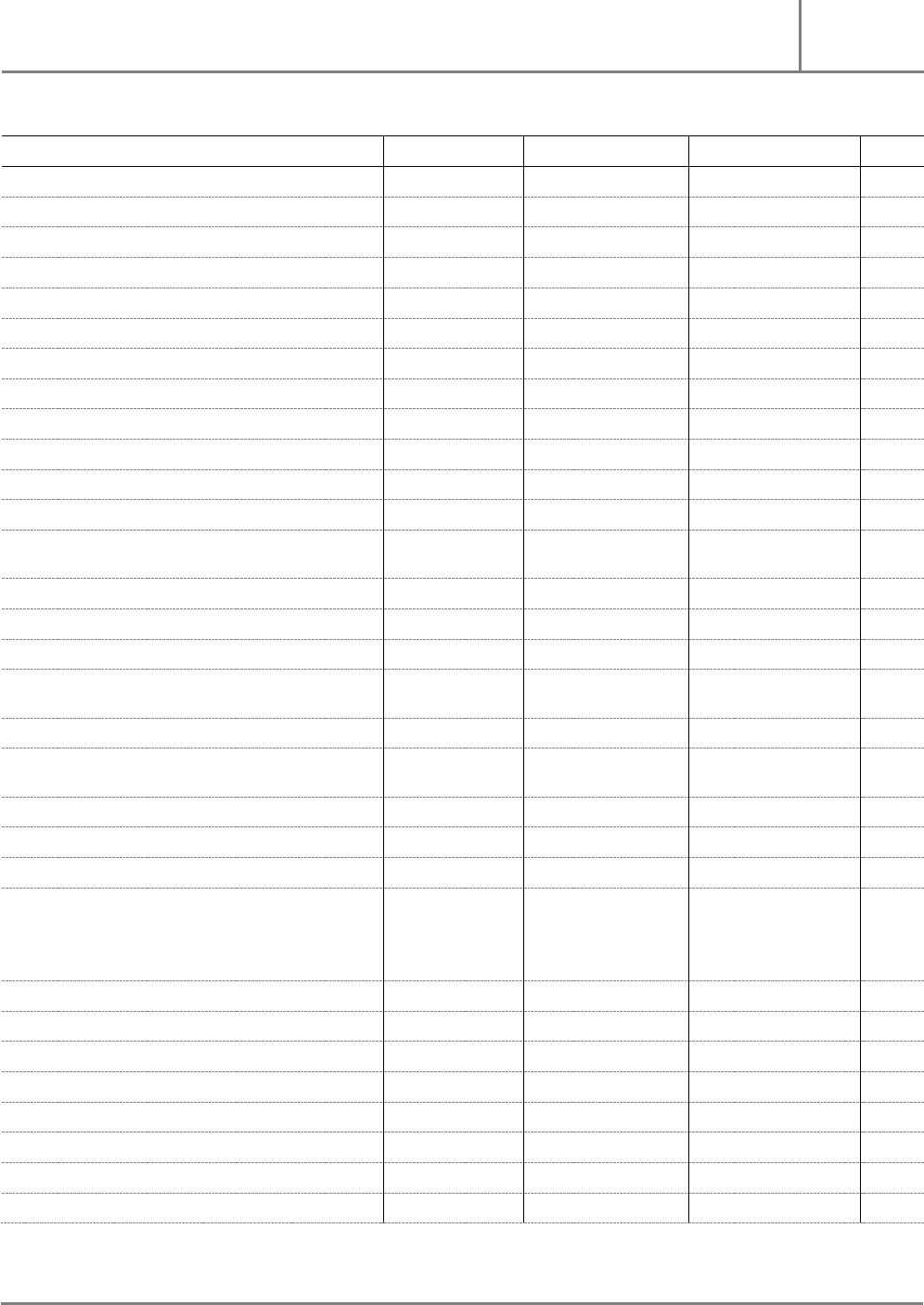

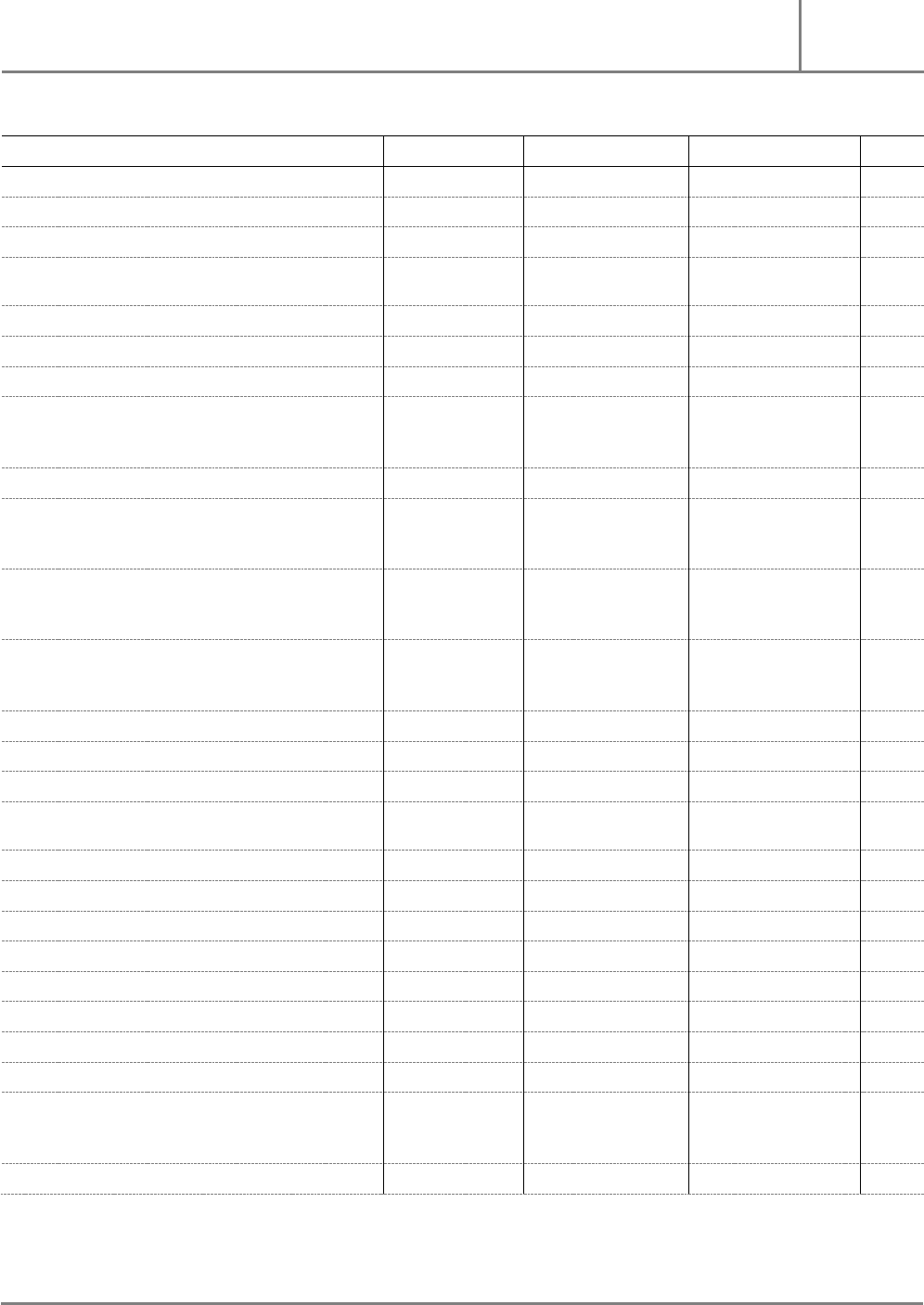

Table of Contents

Div. 4 - 4

Table of Contents

Subdivision E, Exits/Plans

437-004-0405 Exits and Emergency Action Plan ........................................................ E-1

437-004-0450 Emergency Action Plan........................................................................ E-2

Subdivision F, Manlifts

437-004-0570 Manlifts ................................................................................................ F-1

Subdivision G, Health-Environment

437-004-0610 Ventilation ............................................................................................ G-1

437-004-0630 Noise Exposure ................................................................................... G-1

437-004-0650 Ionizing Radiation ................................................................................ G-6

Subdivision H, Hazardous Materials

437-004-0710 Compressed Gases ............................................................................. H-1

437-004-0715 Acetylene ............................................................................................. H-2

437-004-0716 Oxygen ................................................................................................ H-2

437-004-0717 Hydrogen ............................................................................................. H-7

437-004-0720 Flammable Liquids ............................................................................... H-7

437-004-0725 Spray Finishing .................................................................................. H-15

437-004-0770 Explosives and Blasting Agents ......................................................... H-17

437-004-0780 Storage and Handling of Liquefied Petroleum Gases ........................ H-17

437-004-0790 Use of Liquefied Petroleum Gas or Natural Gas in Fields and Orchards

........................................................................................................... H-68

437-004-0800 Storage and Handling of Anhydrous Ammonia .................................. H-69

437-004-0950 Hazardous Waste Operations and Emergency Response ................. H-89

Subdivision I, Protective Equipment

437-004-1005 General Requirements for Protective Equipment ................................. I-5

437-004-1020 Personal Fall Protection ....................................................................... I-7

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Table of Contents

Div. 4 - 5

Table of Contents

437-004-1030 Work Clothing .................................................................................... I-10

437-004-1035 Eye and Face Protection .................................................................... I-11

437-004-1041 Respiratory Protection ....................................................................... I-12

Appendix A to 437-004-1041, Respiratory Protection –

Fit Testing Procedures (Mandatory) ................................................... I-33

Appendix B-1 to 437-004-1041, Respiratory Protection –

User Seal Check Procedures (Mandatory) ......................................... I-59

Appendix B-2 to 437-004-1041, Respiratory Protection –

Respirator Cleaning Procedures (Mandatory) .................................... I-61

Appendix C to 437-004-1041, Respiratory Protection ........................ I-63

Apéndice C de OAR 437-004-1041, Protección de la Respiración .... I-73

Appendix D to OAR 437-004-1041 – Information for Employees

Voluntarily Using Respirators (Mandatory) ........................................ I-83

Apéndice D de OAR 437-004-1041 – Información para Trabajadores

que Usan Respiradores Voluntariamente (Obligatorio) ...................... I-85

437-004-1050 Head Protection ................................................................................. I-87

437-004-1060 Hand, Foot, and Extremity Protection ................................................ I-87

437-004-1070 Working Underway on Water ............................................................. I-89

437-004-1075 Working Over or in Water ................................................................... I-90

Appendix A to Subdivision 4/I – Sample Hazard Assessment for Personal Protective

Equipment (PPE) (Nonmandatory) .................................................... I-91

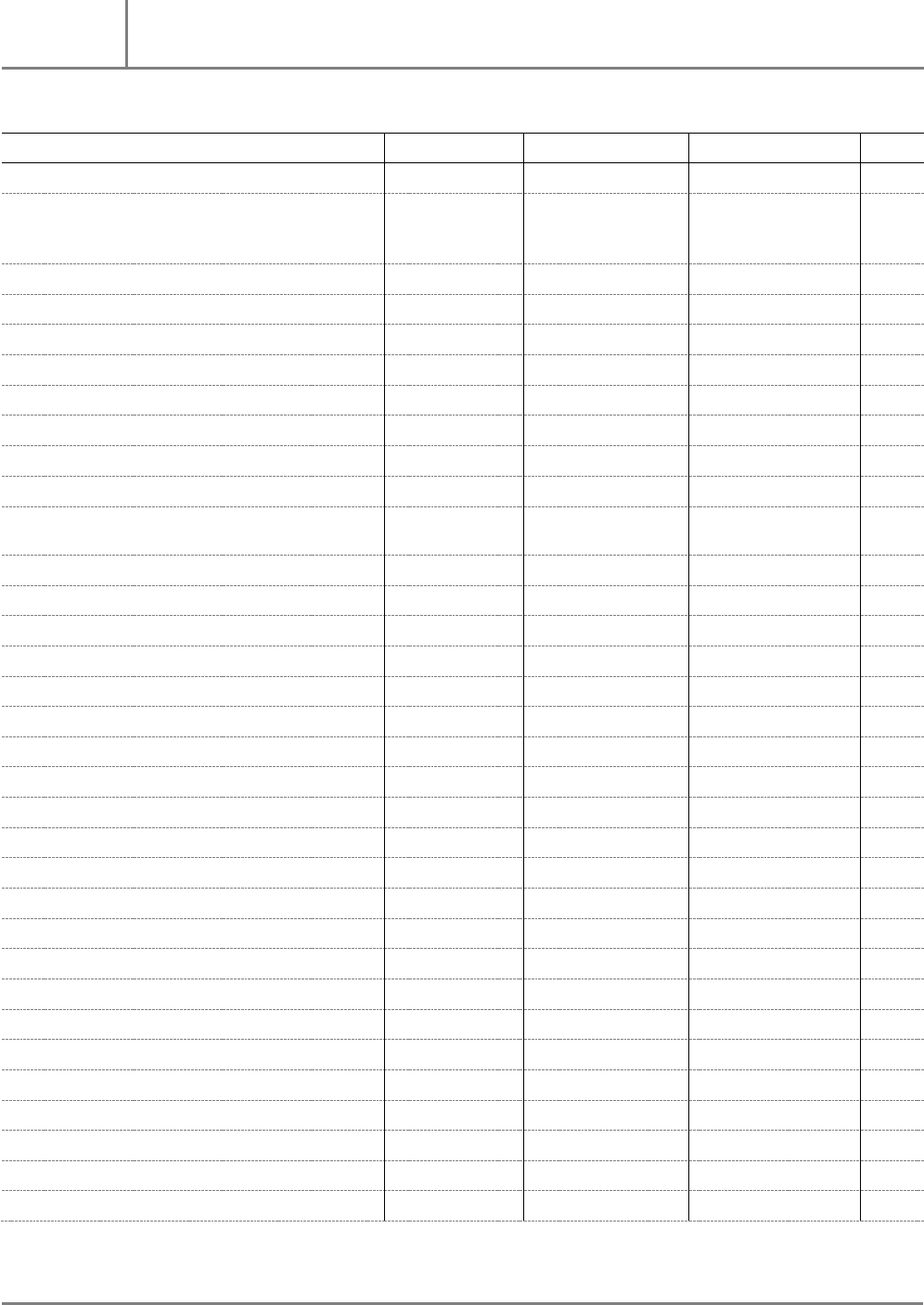

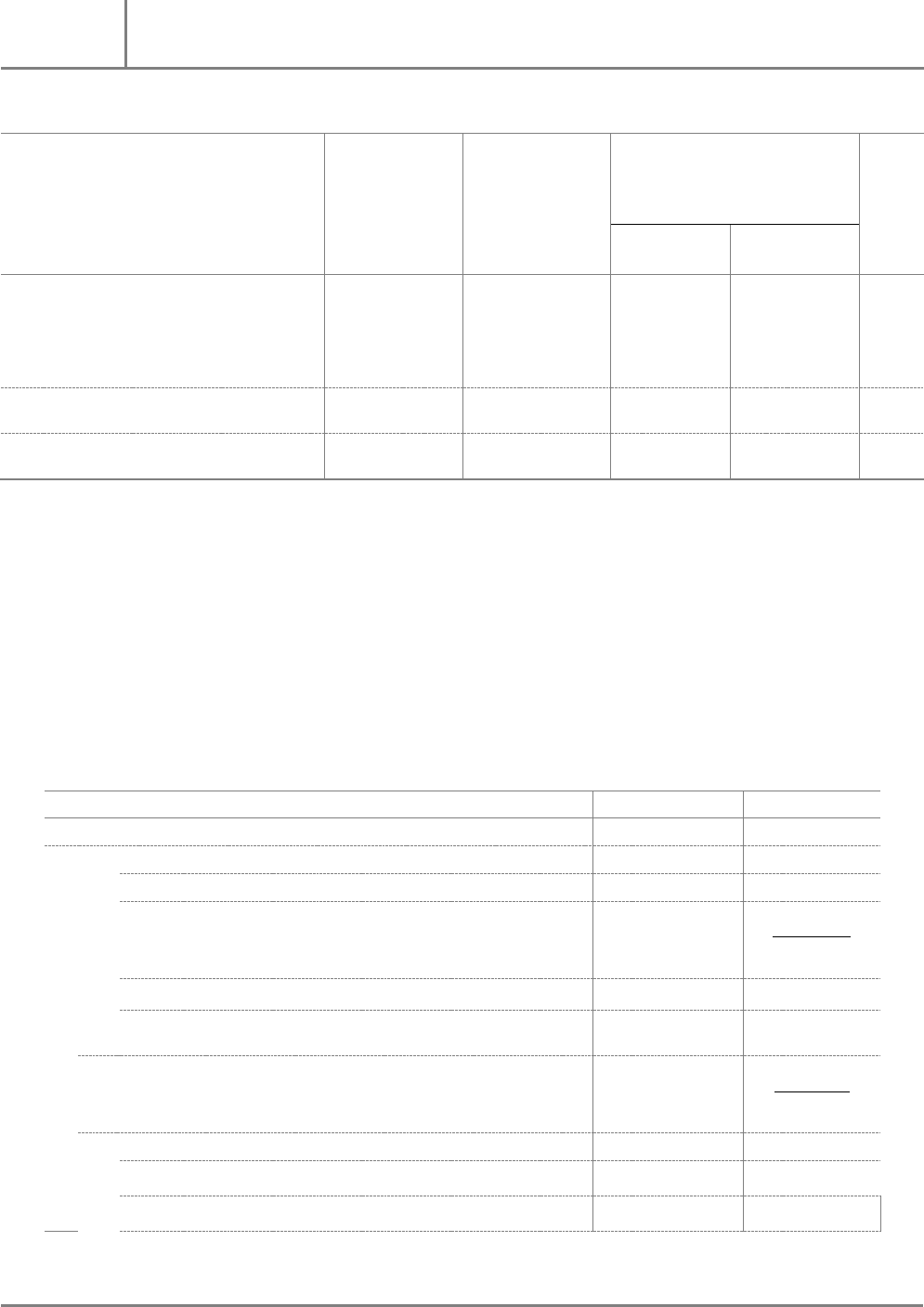

Subdivision J, Work Environment

437-004-1105 Sanitation ............................................................................................ J-5

437-004-1110 Field Sanitation for Hand Labor Work ................................................. J-8

437-004-1115 Repealed ........................................................................................... J-11

437-004-1120 Agricultural Labor Housing and Related Facilities ............................. J-11

437-004-1131 Heat Illness Prevention ..................................................................... J-31

Appendix A - Mandatory Information for Heat Illness Prevention ...... J-41

437-004-1140 Lighting ............................................................................................. J-47

437-004-1150 Safety Colors for Marking Physical Hazards ..................................... J-47

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Table of Contents

Div. 4 - 6

Table of Contents

437-004-1180 Accident Prevention Signs ................................................................. J-47

437-004-1250 Confined and Hazardous Spaces ...................................................... J-49

437-004-1260 Manure Lagoons, Storage Ponds, Vats, Pits and Separators ............ J-54

437-004-1275 The Control of Hazardous Energy (Lockout/Tagout) ......................... J-55

Appendix A – Typical Minimal Lockout Procedure ............................. J-65

Subdivision K, Medical/First Aid

437-004-1305 Medical Services and First Aid ............................................................. K-1

Subdivision L, Fire

437-004-1430 Sources of Fire .................................................................................... L-1

437-004-1440 Required Postings ............................................................................... L-2

437-004-1450 Extinguishers ....................................................................................... L-3

437-004-1460 Fire Prevention Plan ............................................................................ L-4

437-004-1470 Employee Equipment and Training ...................................................... L-4

Subdivision M, Compressed Gasses

437-004-1505 Air Receivers and Pressure Systems ................................................. M-1

437-004-1525 Boilers and Steam Systems ................................................................ M-3

Subdivision N, Material Handling

437-004-1610 General Requirements ......................................................................... N-1

437-004-1630 Conveyors ............................................................................................ N-3

437-004-1670 Automotive Hoists ................................................................................ N-4

437-004-1680 Storage of Hazardous Chemicals ........................................................ N-4

437-004-1700 Forklifts and Other Powered Industrial Trucks ..................................... N-6

437-004-1750 Helicopters ......................................................................................... N-12

437-004-1805 Rope, Chain, Rigging, and Hoists ...................................................... N-14

437-004-1825 Tackle and Hoisting Equipment ......................................................... N-15

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Table of Contents

Div. 4 - 7

Table of Contents

Subdivision O, Equipment Guarding

437-004-1910 General Equipment Guarding ............................................................. O-1

437-004-1940 Farm Field Equipment ......................................................................... O-3

437-004-1970 Farmstead Equipment ......................................................................... O-5

437-004-2000 Powered Saws .................................................................................... O-8

437-004-2100 Grinders ............................................................................................ O-11

Subdivision P, Small Tools

437-004-2220 General Requirements - Small Tools ................................................... P-1

437-004-2230 Guarding of Portable Powered Tools ................................................... P-2

437-004-2240 Power Lawnmowers ........................................................................... P-14

437-004-2260 Other Portable Tools and Equipment ................................................. P-16

Subdivision Q, Welding

437-004-2310 General Requirements ........................................................................ Q-1

437-004-2350 Oxygen-Fuel Gas Welding and Cutting ............................................... Q-6

437-004-2400 Arc Welding and Cutting ................................................................... Q-12

Subdivision S, Electricity

437-004-2810 General Requirements ......................................................................... S-1

437-004-2850 Temporary Lighting and Wiring ............................................................ S-2

437-004-2860 Flexible Cable and Extension Cords .................................................... S-3

437-004-2870 Attachment Plugs and Receptacles ..................................................... S-4

437-004-2880 Cord and Plug-Connected Equipment ................................................. S-5

437-004-2900 Grounding and Bonding ....................................................................... S-6

437-004-2950 Switches and Circuit Breakers ............................................................. S-7

437-004-3000 Identification and Load Ratings ............................................................ S-8

437-004-3050 Work Near Overhead Lines.................................................................. S-8

437-004-3075 Agricultural Buildings with Special Hazards ......................................... S-9

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Table of Contents

Div. 4 - 8

Table of Contents

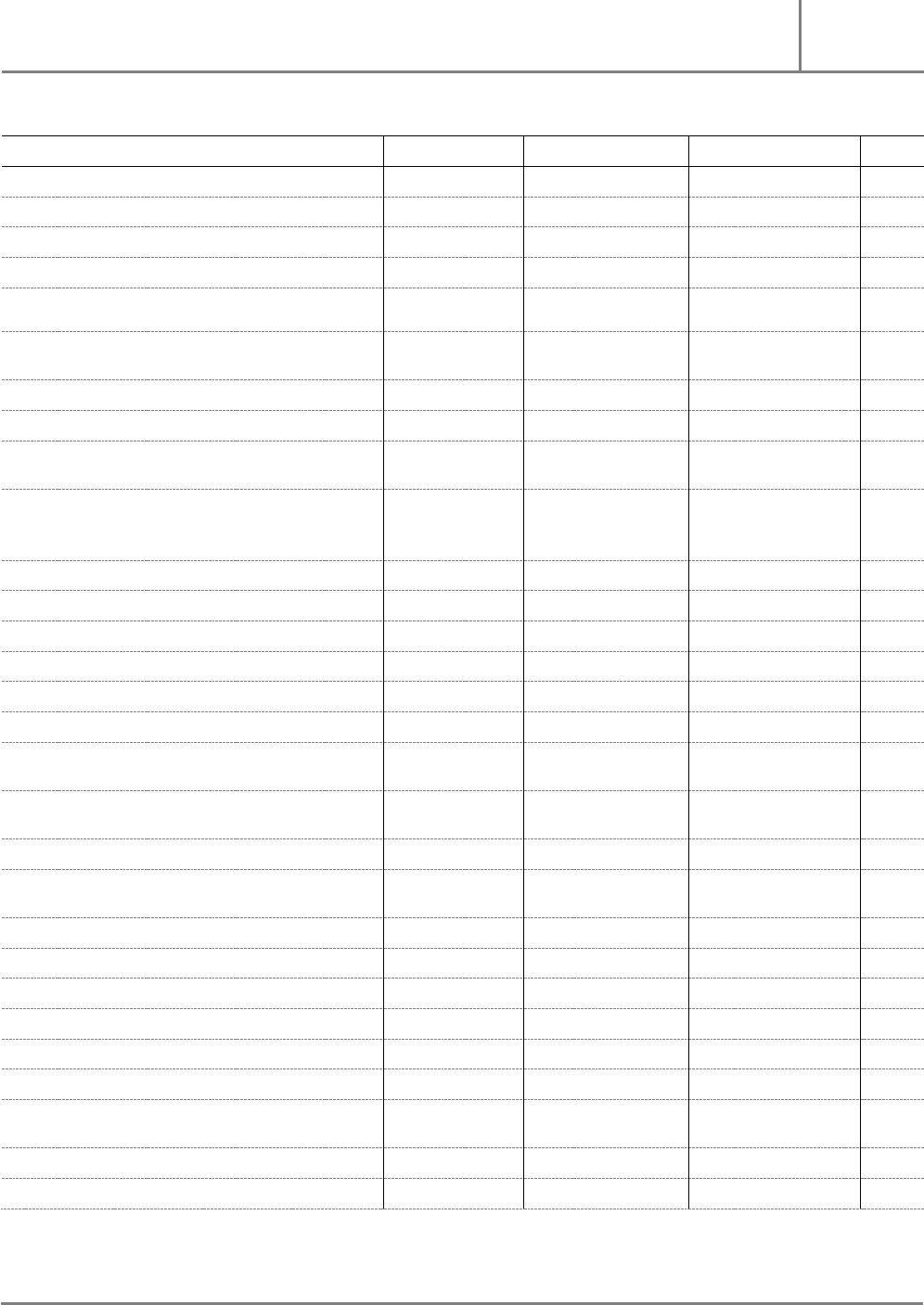

Subdivision T, Miscellaneous

437-004-3100 Excavation ........................................................................................... T-1

Subdivision U, Vehicles

437-004-3410 Agricultural, Commercial and Industrial Vehicles ................................. U-1

Appendix A to 437-004-3410, Specific Equipment ............................... U-9

437-004-3420 Working from Vehicles and Vehicle Loads ......................................... U-11

437-004-3430 Training for Agriculture Tractor Operators ......................................... U-11

437-004-3460 Industrial Vehicles .............................................................................. U-12

437-004-3480 Bridges, Roads and Ramps ............................................................... U-12

437-004-3550 Servicing Multipiece and Single Piece Rim Wheels ........................... U-13

437-004-3600 Roll-Over Protective Structures (ROPS) for Tractors in Agriculture ... U-13

437-004-3650 Roll-Over Protective Structures - Industrial Vehicles ......................... U-17

437-004-3660 Vehicle-Mounted Elevating and Rotating Work Platforms.................. U-18

Subdivision W, Worker Protection Standard

437-004-6000 Adoption by Reference of Federal Standard ....................................... W-1

437-004-6001 Expiration and Implementation Dates ................................................. W-2

Subpart D General Provisions

170.301 Scope and Purpose ............................................................................ W-5

170.303 Applicability of this part ....................................................................... W-5

170.305 Definitions ........................................................................................... W-6

170.309 Agricultural employer duties .............................................................. W-11

170.311 Display requirements for pesticide safety information and pesticide

application and hazard information ................................................... W-14

170.313 Commercial pesticide handler employer duties ................................ W-19

170.315 Prohibited actions ............................................................................. W-22

Subpart E Requirements for Protection of Agricultural Workers

170.401 Training requirements for workers .................................................... W-25

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Table of Contents

Div. 4 - 9

Table of Contents

437-004-6401 Effective dates for worker training programs in Oregon .................... W-26

170.403 Establishment-specific information for workers ................................. W-29

170.405 Entry restrictions associated with pesticide applications ................... W-30

437-004-6405 Restrictions associated with outdoor production pesticide

applications ...................................................................................... W-30

437-004-6406 Pesticide spray drift and innovative methods .................................... W-34

170.407 Worker entry restrictions after pesticide applications ........................ W-37

170.409 Oral and posted notification of worker entry restrictions ................... W-37

170.411 Decontamination supplies for workers .............................................. W-44

Subpart F Requirements for Protection of Agricultural Pesticide Handlers

170.501 Training requirements for handlers ................................................... W-47

437-004-6501 Handler training programs in Oregon ................................................ W-48

437-004-6502 Oregon requirements for Worker Protection Standard trainers of

handlers who qualify using train-the-trainer programs ...................... W-49

170.503 Knowledge of labeling, application-specific, and establishment-

specific information for handlers ....................................................... W-50

170.505 Requirements during applications to protect handlers,

workers, and other persons............................................................... W-51

170.507 Personal protective equipment .......................................................... W-52

437-004-6508 Respiratory Protection ...................................................................... W-55

170.509 Decontamination and eye flushing supplies for handlers .................. W-58

437-004-6509 Emergency eye-washes and eye flushing supplies ........................... W-59

Subpart G Exemptions, Exceptions and Equivalency

170.601 Exemptions ....................................................................................... W-61

170.603 Exceptions for entry by wokers during restricted-entry

intervals............................................................................................. W-62

170.605 Agricultural employer responsibilities to protect workers entering

treated areas during a restricted-entry interval ................................. W-65

170.607 Exceptions to personal protective equipment requirements

specified on pesticide product labeling ............................................. W-67

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Table of Contents

Div. 4 - 10

Table of Contents

Subdivision Z, Chemical/Toxins

437-004-9000 Oregon Rules for Air Contaminants .................................................... Z-5

437-004-9010 Fumigated Areas .............................................................................. Z-32

437-004-9050 Asbestos ........................................................................................... Z-32

437-004-9090 13 Carcinogens ................................................................................. Z-34

437-004-9600 Lead .................................................................................................. Z-34

437-004-9620 Cadmium .......................................................................................... Z-35

437-004-9626 Chromium (VI) .................................................................................. Z-35

437-004-9640 Benzene ............................................................................................ Z-36

437-004-9650 Bloodborne Pathogens ..................................................................... Z-37

437-004-9710 Acrylonitrile ....................................................................................... Z-38

437-004-9720 Thiram ............................................................................................... Z-38

437-004-9740 Ethylene Oxide ................................................................................. Z-44

437-004-9760 Formaldehyde ................................................................................... Z-44

437-004-9780 Methylenedianiline ............................................................................ Z-44

437-004-9791 Protection from Wildfire Smoke ........................................................ Z-45

Appendix A to 437-004-9791: Mandatory Workplace Guidance

for the Use of Filtering Facepiece Respirators to Address

Wildfire Smoke .................................................................................. Z-53

Appendix B to 437-004-9791: Information for Wildfire Smoke

Protection .......................................................................................... Z-55

437-004-9800 Hazard Communication Standard for Agricultural Employers ........... Z-57

437-004-9830 Retention of Department of Transportation (DOT) Markings,

Placards and Labels ......................................................................... Z-71

437-004-9850 Pipe Labeling .................................................................................... Z-71

Appendix A to 437-004-9850 Pipe Labeling (Non-Mandatory) .......... Z-75

437-004-9860 Hazardous Chemicals in Laboratories .............................................. Z-77

List of Tables for Division 4, Subdivision Z ........................................................................ Z-79

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Historical Notes

Div. 4 - 11

Historical Notes

Historical Notes for Division 4

Note 1: The OR-OSHA Advisory Committee of Small Agricultural Employers provided the philo-

sophical and structural guidance for this standard, Division 4, Agriculture. Most farmers, ranchers and

growers were committed to have only one book of OR-OSHA standards. We began this pro- cess

committed to not enacting any new standards. However, the agricultural community soon realized the

need for some new standards. We emphasize that most of the new standards do not represent new

requirements for employers. In most cases the new standard merely consolidates and clarifies what

was done previously from a variety of sources. Some examples are forklift driver training, storage of

chemicals and pay for personal protective equipment. This standard is written in plain English and is

formatted for easy reading.

OR-OSHA Admin. Order 4-1998, filed 8/28/98, effective 10/1/98.

Note 2: Oregon OSHA adopted changes to the standard for Agricultural employers, Division 4.

These changes are the result of proposed legislation introduced by the Oregon Farm Bureau

Federation.

Oregon OSHA negotiated changes to these administrative standards with the Farm Bureau to provide

the needed updating of the standards without completing the legislative process.

The changes effect only the standard on Safety Committees, Chapter C.

The effect of these changes is to modify the requirements for safety committees for Oregon

agricultural employers with more than 10 non-seasonal workers. The changes eliminate several

paperwork requirements. They also move the standard to a more performance-oriented approach.

For smaller agricultural employers, the changes eliminate required safety committees. These are

employers who have fewer than 11 non-seasonal workers but who may hire enough seasonal workers

to swell their force temporarily during a particular cycle.

The term seasonal worker is defined for the first time. For the sake of consistency, the definition

mirrors others used by various government agencies in the regulation of agriculture.

Employers with small non-seasonal work forces must hold special orientation meetings for their

seasonal workers to assure that these people are not excluded from the training and information they

need to work safely.

Comments received at the public hearing on April 23, 1999, and throughout the time the amendments

were proposed, were in agreement with the changes.

OR-OSHA Admin. Order 2-1999, filed 4/30/99, effective 4/30/99.

Note 3: During the last growing season issues were raised that led to the establishment of a work

group to develop solutions. Of particular concern was a requirement for a second means of exit even

in single room dwellings that were in compliance with Building Codes and Fire Marshal rules.

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Historical Notes

Div. 4 - 12

Historical Notes

A committee of representatives of labor, the agricultural community, elected officials, and state

agencies whose standards affect labor housing, worked on developing the changes to 437-004-1120,

Agricultural Labor Housing and Related Facilities, in Division 4/J, Agriculture/Work Environment. We

are making similar changes to 437-002-0142, Labor Camps, in general industry.

We regrouped some subjects into more logical categories. Wording or grammar in several rules

changed to make the rule easier to follow and/or enforce.

Several definitions changed to reflect current practices or to more closely match the same definitions

in other state regulatory documents such as those of the Building Codes Division.

A date (December 15, 1989) is now part of a few rules to make OR-OSHA requirements more

synchronous with those of the Building Codes Division (BCD). For certain issues, any housing built or

remodeled on or after that date must comply with BCD standards on those issues. Housing built or

remodeled before that date must meet standards in effect at the time of the work. For most other

issues compliance is based on the particular standard in effect at the time the work was done.

Housing units built or remodeled on or after December 15, 1989 must comply with new OR-OSHA

rules and the state building code rules on emergency exits. Those rules give location and design

criteria. One-room living areas no longer need a second emergency exit. Older multi-room units must

comply with the old OR-OSHA rules.

We added a paragraph to prohibit citations resulting from housekeeping practices of camp occupants.

Recyclable materials like cans and bottles are no longer trash for the purposes of certain rules

governing trash and refuse.

Operators must post their street numbers so that responding emergency vehicles can see them from

the street.

Requirements for toilets, handwashing and bathing facilities changed to read one unit for each fifteen

employees or fraction thereof.

Requirements for handling and control of garbage are now restricted to outside of buildings and

certain recyclable materials are not considered garbage for that rule.

Based on comments we received, three categories of registration exemptions are eliminated from the

new rules. Based on ORS 654.705(7) Oregon OSHA believes these categories are already exempt

from registration and need not be repeated in the rules. They are:

Dwellings occupied by the owner or owning family; or

Dwellings occupied year-round by employees who are members of a nuclear family (parents, children,

grandparents or siblings); and

The original structure and any remodeling conformed to building codes or manufactured dwelling

regulations in effect at the time they were done.

Oregon OSHA received many comments on the issue of required heating during specified months of

the year. After consideration of all the comments and analysis of the economic impact versus the

potential impact of safety and health, this rule remains unchanged.

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Historical Notes

Div. 4 - 13

Historical Notes

The following changes are proposed to have an effective date of October 1, 2000:

Housing operators must now provide a mattress or pad for any bed or bunk. The bed or bunk must

keep the mattress at least 6 inches off the floor.

Each unit must have a working smoke detector at the time of initial occupancy. The operator is not

responsible for actions of occupants to defeat or disable the detector.

Tent must be made of or treated with flame retardant materials.

OR-OSHA Admin. Order 5-2000, filed 5/18/00, effective 6/1/00 (some portions effective 10/1/00).

Note 4: Oregon’s Legislative Counsel notified OR-OSHA that OAR 437-004-0250(6) did not con-

form to the requirements of ORS 654.182(d). The adopted changes bring the administrative rule into

agreement with the statute. OAR 437-004-0250 is the rule for Safety Committees in Division 4/C,

Agriculture/Safety Awareness.

OR-OSHA Admin. Order 7-2000, filed 7/26/00, effective 7/26/00.

Note 5: Oregon OSHA replaced rules, almost 30 years old, in Division 2, General Industry, about

working on or over water. Existing rules reflect the original intent to apply mostly to log ponds and

similar applications, and do not reflect either current practices or technology. The new rules are the

result of a series of meetings with effected parties including the United States Coast Guard.

Oregon OSHA also placed rules about working on or over water in Division 4, Agriculture. Oregon’s

old standard, Division 81, Agricultural Operations, had these rules but they were erroneously left out

during the writing of the new standard, Division 4, Agriculture. This adoption is to put them back and

update the language for the same reasons as stated above.

In response to public comments, we made one change from the original proposal for both agriculture

and general industry. We added language exempting workers covered by Oregon standards for

commercial divers. The reasoning was that the proposal could have been construed to require divers

to wear personal flotation devices (PFDs).

OR-OSHA Admin. Order 1-2001, filed 1/18/01, effective 3/1/01.

Note 6: Oregon OSHA standards must be as effective as federal OSHA. There were slight

differences in the air contaminants rules. Therefore, OR-OSHA has modified three substances:

Carbon disulfide; Ethylene dibromide; and Mercury and Mercury organo (alkyl), to match federal

OSHA’s standard in construction and maritime. For uniformity, Oregon initiated air contaminant rules

in general industry, construction and agriculture will all reflect the amendments.

Oregon added the skin designation to the three substances listed above. Also, Oregon changed the

PEL to 25 ppm ceiling value for Ethylene dibromide (currently at 30 ppm).

OR-OSHA Admin. Order 4-2001, filed 2/5/01, effective 2/5/01.

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Historical Notes

Div. 4 - 14

Historical Notes

Note 7: Oregon OSHA adopted changes to Division 4/H, OAR 437-004-0790, Use of Liquefied

Petroleum Gas or Natural Gas in Fields and Orchards, to bring them into harmony with requirements

of the Oregon Office of State Fire Marshal and the Oregon Building Codes Division. The changes

also clarify the application by excluding portable equipment. The requirement to guard certain tank

installations is deleted after consultation with orchardists and LPG industry representatives. This

requirement was originally set for industrial applications where the hazard of vehicle contact with the

tanks is substantial and frequent. Isolated orchard locations do not present this hazard.

OR-OSHA Admin. Order 7-2001, filed 5/15/01, effective 5/15/01.

Note 8: Oregon OSHA amended the air contaminants standard in Division 4/Z, Agriculture/

Chemical/Toxins. The change is to Table Z-2, to the entry for Methylene Chloride. When federal

OSHA amended the Methylene Chloride standard in general industry, construction, and shipyard

employment, OR-OSHA inadvertently did not amend the table in our agriculture standard to reflect the

lower exposure limit of 25ppm. The exposure limit of 25ppm for methylene chloride is now the same

in general industry, construction, agriculture, and shipyard employment.

OR-OSHA Admin. Order 9-2001, filed 9/14/01, effective 9/14/01.

Note 9: Based on the most recent injury and illness data provided by the Department’s Research and

Analysis Section, the trigger for the top 10 percent of lost work day cases incidence rates for

agriculture has changed from two to one. This change in the administrative rules is precipitated by

ORS 654.176(b)(A). The rule affected is OAR 437-004-0250(1)(b) and note, Safety Committees, in

Division 4/C, Agriculture/Safety Committees.

OR-OSHA Admin. Order 1-2002, filed 2/15/02, effective 2/15/02.

Note 10: The Environmental Protection Agency (EPA), published in the September 1, 2004 Federal

Register, amendments to 40 CFR 170, Worker Protection Standard. EPA amended the 1992

Pesticide Worker Protection Standard to permit optional use of separable glove liners beneath

chemical-resistant gloves. This amendment also makes optional the provision that agricultural pilots

wear gloves when entering or leaving aircraft. All other provisions of the Worker Protection Standard

are unaffected by this rule. EPA believes that these changes will reduce the cost of compliance and

will increase regulatory flexibility without increasing potential risks.

Oregon OSHA adopted these changes as published. These changes are in OR-OSHA’s Division

4/W, Agriculture/Worker Protection Standard.

OR-OSHA Admin. Order 7-2004, filed 12/30/04, effective 12/30/04.

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Historical Notes

Div. 4 - 15

Historical Notes

Note 11: A new Respiratory Protection standard was adopted in Division 4/I, Agriculture. OAR 437-

004-1041, Respiratory Protection was adopted as OR-OSHA Administrative Order 3-2006 on June 7,

2006, but will not be effective until March 1, 2007.

The current 437-004-1040, Respiratory Protection will remain in effect through February 28, 2007.

Oregon OSHA will have both standards on the web site and in hard copy until March 2007.

The Respiratory Protection Standard was reworded for clarity and plain language, and to bring the

rules up to Division 2/I standards having one rule for all respirator users.

Summary of changes:

• There are new requirements for voluntary use of respirators. You must provide respirator

users with the information contained in Appendix D, and have a medical evaluation required

for respirators with the exception of filtering face-pieces, and have cleaning, storing and

maintenance procedures in the program.

• There is a requirement for annual fit-testing of required use of respirators.

• There is a change from annual medical evaluations to a medical evaluation before the first fit-

test.

• New appendices A, B1, B2 and D were added for procedures on fit-testing (A), user seal

check (B1) and proper cleaning (B2) the medical questionnaire was moved to (C) and

voluntary use information (D). The mandatory appendices C and D are also in Spanish.

• There is a section on interior structural firefighting requiring the two in two out rules.

• Training is required annually.

• A change out schedule for canisters and cartridges is required.

OR-OSHA Admin. Order 3-2006, filed 6/7/06, effective 3/1/07.

Note 12: This rule adds new requirements for exposures to hexavalent chromium, including a lower

airborne permissible exposure limit, an action level, airborne exposure assessments, regulated areas,

change and washing facilities, medical surveillance, and training.

These changes are required to keep OR-OSHA standards as effective as Federal OSHA.

Oregon OSHA did not adopt the exception for pesticide use. Federal OSHA does not regulate the

use of pesticides because the Environmental Protection Agency (EPA) regulates these exposures

through the Worker Protection Standard (WPS). However, since Oregon OSHA enforces the WPS

this exemption does not apply in Oregon.

Oregon OSHA adopted these changes into general industry, construction, agriculture, and maritime.

The proposed amendments to the permissible limit for airborne concentrations of respirable silica

were not adopted in this rulemaking.

OR-OSHA Administrative Order 6-2006, adopted and effective August 30, 2006.

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Historical Notes

Div. 4 - 16

Historical Notes

Note 13: Oregon OSHA adopted changes in 16 subdivisions of Division 4, Agriculture, including:

clarify language, correct/add reference changes, add notes, the lead standard is removed from

Division 4 and OAR 437-002-1910.1025 (Division 2/Z) is referenced, added requirements to Roll-Over

Protective Structures (ROPS) due to Federal OSHA changes, changes to General Requirements in

Electricity, a new paragraph on varmint killers, and a new rule on fumigated areas.

OR-OSHA Administrative Order 9-2006, adopted and effective September 22, 2006.

Note 14: Oregon OSHA adopts the Federal OSHA changes as they appear in the August 24, 2006

Federal Register. These changes revise the existing rules on respiratory protection, adding

definitions and new language that establishes Assigned Protection Factors (APFs) and Maximum Use

Concentrations (MUCs) for respirator use. The revisions also supersede the respirator selection

provisions of existing substance-specific standards with these new APFs (except for the respirator

selection provisions of the 1,3-Butadiene Standard).

Federal OSHA developed the final APFs after thoroughly reviewing the available literature, including

chamber-simulation studies and workplace protection factor studies, comments submitted to the

record, and hearing testimony. The final APFs provide employers with critical information to use when

selecting respirators for employees exposed to atmospheric contaminants found in general industry,

construction, shipyards, longshoring, and marine terminal workplaces. Oregon OSHA also adopts

these changes into Division 4, Agriculture. Proper respirator selection using APFs is an important

component of an effective respiratory protection program. Accordingly, Federal OSHA concludes that

the final APFs are necessary to protect employees who must use respirators to protect them from

airborne contaminants.

OR-OSHA Administrative Order 10-2006, adopted and effective November 30, 2006. Changes

to OAR 437-004-1041 (Agriculture) are effective March 1, 2007.

Note 15: Oregon OSHA is correcting typographical errors and incorrect references, which will add

clarity to the Respiratory Protection Standard in Division 4, Agriculture.

OR-OSHA Administrative Order 3-2007, adopted and effective August 13, 2007.

Note 16: After meeting with stakeholders, negotiations with Federal OSHA, and giving consideration

to comments received at hearings, Oregon OSHA adopts these changes to OAR 437-004-1120,

Agricultural Labor Housing (ALH) and Related Facilities, in Division 4/J, Agriculture/Work

Environment, to make our rules “as effective” as those of Federal OSHA.

The major changes are:

Beginning on January 1, 2018, the rule will require all agricultural labor housing, where workers cook,

live and sleep in the same area, to provide 100 square feet per occupant. Square footage

requirements for sleep-only areas will not change.

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Historical Notes

Div. 4 - 17

Historical Notes

For units built after April 3, 1980, at least one-half the required floor space in each living area must

have a minimum ceiling height of 7 feet. Floor space with a ceiling height less than 5 feet does not

count toward the minimum required floor space.

Beginning on January 1, 2018, only areas with a 7 foot ceiling height will count toward the required

square footage of any living or sleeping area.

Ratios of sinks and showers will change starting on April 1, 2009. The rules on laundries and window

requirements will also change on April 1, 2009.

Delayed effective dates are to give operators time to secure needed permits from local authorities and

to arrange financing for projects that require major work.

Oregon OSHA removed references to tents. Tents are acceptable labor housing when they meet all

the criteria in the rule, just like any other style housing.

The rule now requires heat be available in all ALH without regard to the time of year.

The rule now requires ‘livestock operations’ be at least 500 feet from all ALH unless the employees in

the housing are employed to tend or otherwise work with the animals. This does not apply to animals

owned by the housing occupants.

OAR 437-002-0142 Temporary Labor Camps in Division 2/J, General Industry/Environmental

Controls, is also amended. The entire text of the rule is removed and new language is added stating

that OAR 437-004-1120 applies in General Industry, Construction, and Forest Activities as well as

Agriculture, except paragraphs (5), (6)(p), and (24).

This is OR-OSHA Administrative Order 4-2008, adopted March 24, 2008 and effective May 1,

2008.

Note 17: Oregon OSHA adopted the Federal OSHA changes as they appear in the November 15,

2007 Federal Register, into Division 2/I, Personal Protective Equipment, Division 3/E, Personal

Protective and Life Saving Equipment, and Division 5, Maritime Activities. The changes codify and

clarify the employers’ responsibility to provide and pay for protective equipment that is necessary for

employees to perform their jobs safely.

In addition to the Federal OSHA changes, Oregon OSHA proposes to replace the existing language in

Division 4/I, Protective Equipment, with language comparable to the new Federal OSHA language for

clarity.

This is OR-OSHA Administrative Order 5-2008, adopted May 1, 2008 and effective May 15, 2008.

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Historical Notes

Div. 4 - 18

Historical Notes

Note 18: This rulemaking is to keep Oregon OSHA in harmony with recent changes to Federal

OSHA’s standards. We are removing several references to consensus standards that have

requirements that duplicate, or are comparable to, other OR-OSHA rules; this action includes

correcting a paragraph citation in one of these rules. We are also removing a reference to American

Welding Society standard A3.0-1969 ("Terms and Definitions") in our general industry welding

standards. This rulemaking is part of a continuing effort to update references to consensus and

industry standards used throughout our rules.

OR-OSHA adopts the changes in general industry as published in the December 14, 2007 Federal

Register with the following exceptions:

• Division 2/H, 1910.94(c)(1)(ii), and (3) - In Oregon 437-002-0107 Spray Finishing applies.

• Division 2/H, 1910.107 - In Oregon 437-002-0107 Spray Finishing applies.

• Division 2/R, 1910.261 - In Oregon 437-002-0312 Oregon Rules for Pulp, Paper, and

Paperboard Mills applies.

A reference to American National Standard Safety Requirements for Explosive-Actuated Fastening

Tools, ANSI A10.3-1995 is removed in Division 4/P, Agriculture/Small Tools.

This is OR-OSHA Administrative Order 7-2008, adopted and effective May 30, 2008.

Note 19: These changes are necessary to resolve issues expressed by Federal OSHA toward making

our rules at least as effective as theirs. In addition, the removal of the heater language is to recognize

new safety technology.

437-004-1120(16) Living Areas.

We will delete paragraph (c)(B) to reflect changes in heater technology. Paragraph (C) will become

(B) and (D) will become (C). Paragraph (B) is adequate to address any hazards related to ribbon-type

heaters as they now come with safety devices to shut them off if they overheat.

437-004-1120(16) Living Areas.

Wording added to paragraph (n) will close a gap in coverage pointed out by Federal OSHA. The result

is that existing housing will be good until the 2018 change date unless it is remodeled. New

construction and existing housing remodeled between this adoption and 2018 will have to meet the

new requirements in paragraph (n).

437-004-1120(18) Common use cooking and eating facilities and equipment.

Federal OSHA requires adding this language to be as effective as their rule. It requires enclosed,

screened shelters for common use cooking and eating facilities.

437-004-1120(19) Dining Halls and equipment.

Federal OSHA requires adding this language to be as effective as their rule. It requires enclosed,

screened shelters for dining halls.

This is Oregon OSHA Administrative Order 1-2009, adopted and effective January 26, 2009.

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Historical Notes

Div. 4 - 19

Historical Notes

Note 20: In Oregon, Oregon OSHA administers and enforces the pesticide Worker Protection

Standard (WPS: 40 CFR 170) as adopted in Division 4, Agriculture, Subdivision W, OAR 437-004-

6000.

This rulemaking amends OAR 437-004-6000 to reflect non-substantive corrections and technical

amendments that were published in the Federal Register from 2006 through 2009.

Oregon OSHA is also amending the pesticide Worker Protection Standard (WPS) in Division 7, Forest

Activities, Subdivision A, General Requirements, OAR 437-007-0010, to clarify the references in

Division 7 to the WPS in Division 4.

In addition, Oregon OSHA is amending Division 2, General Industry, Subdivision Z, Toxic and

Hazardous Substances, by adopting a new rule (OAR 437-002-0170) to clarify that under certain

circumstances all parts of the Worker Protection Standard (WPS) apply to general industry

workplaces, and are a part of Division 2 in addition to, and not instead of, any other part of Division 2.

Members of the public submitting written comments expressed support for the changes but noted that

the proposed amendments (being non-substantive) do not go far enough to improve the protection of

Oregon’s affected workers from exposure to pesticides. The changes suggested by these

commenters were outside the parameters of this rulemaking.

This is Oregon OSHA Administrative Order 9-2009, adopted and effective September 21, 2009.

Note 21: This rulemaking is to keep Oregon OSHA in harmony with recent changes to Federal

OSHA’s standards.

Federal OSHA revised the personal protective equipment (PPE) sections of its general industry,

shipyard employment, longshoring, and marine terminals standards concerning requirements for eye-

and face-protective devices, and head and foot protection.

Federal OSHA updated the references in its regulations to reflect more recent editions of the

applicable national consensus standards that incorporate advances in technology. Federal OSHA

requires that PPE be safely designed and constructed for the tasks performed.

Amendments to the PPE standards include a requirement that filter lenses and plates in eye-

protective equipment meet a test for transmission of radiant energy such as light or infrared.

Oregon OSHA adopted the changes in general industry and maritime activities as published in the

September 9, 2009 Federal Register. The updated references are also made in Oregon OSHA’s

Division 4, Agriculture, and Division 7, Forest Activities.

This is Oregon OSHA Administrative Order 2-2010, adopted and effective February 25, 2010.

Note 22: These changes result from legislation, input from the regulated community and input from

Oregon OSHA staff.

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Historical Notes

Div. 4 - 20

Historical Notes

Changes to Subdivision 4/A, Agriculture/ General Subjects, at OAR 437-004-0002, Scope, cross-

reference and clarify the SIC and NAICS codes to which the Division 4 rules apply. A duplicate rule for

adoption of the Worker Protection Standard (OAR 437-004-0004) was eliminated. In OAR 437-004-

0099, General Standards, a requirement at (1)(b) was rewritten in plain language. At (3), rules for

inspecting workplaces, and at (4)(a), rules for investigating time-loss injuries and illnesses were cross-

referenced with the numbering changes in 4/C Safety Committees and Safety Meetings.

Changes in Subdivision 4/C, Safety Awareness, fulfill Oregon OSHA’s responsibility under a recent

legislative mandate to require all Oregon employers, regardless of size, to have either a safety

committee or to hold safety meetings.

The safety committee rule, OAR 437-004-0250 is repealed on the effective date, January 1, 2011, and

is being replaced with OAR 437-004-0251, Safety Committees and Safety Meetings, incorporating the

changes required by the legislative mandate. The scope of the rule is defined as all agricultural

employers with workers, excluding seasonal workers. All employers with workers can have a safety

committee. The number of (nonseasonal) workers, both full-time and part-time, per location determine

whether the employer also has the option of holding monthly safety meetings instead of having a

safety committee.

The special needs of agricultural employers are addressed by maintaining separate safety orientation

requirements for employers of seasonal workers, as outlined in OAR 437-004-0240, Safety

Orientation for Seasonal Workers. The original definition was maintained in the final rule: Seasonal

workers are “employed in a job tied to a certain time of year by an event or pattern and for not more

than 10 months in a calendar year.” Additional notes were added to this section to cross reference

and explain the minimum training and orientation requirements for seasonal workers who perform only

“hand labor operations” as defined in the rule.

The Division 4/C rules for employers of both seasonal and non-seasonal workers now specifically

state – at OAR 437-004-0240(2)(b) and 437-004-0251(2)(b) – that safety awareness information must

be communicated “in a manner that workers can understand.” Employers with employees who have

language barriers must “include content that is either translated into the language used to hire and

supervise these employees or that is otherwise effectively conveyed, such as through visual media.”

Changes in Subdivision 4/K, Agriculture/ Medical and First Aid, at OAR 437-004-1305, are mostly

stylistic, putting the existing requirements for first aid, emergency medical treatment, the emergency

medical plan, and emergency eyewash and safety showers into clearer language.

Paragraph (5), Emergency eyewash and shower facilities, are rewritten for the final rule to address

concerns by commenters. The final rule clarifies when eyewash, shower equipment, or both are

required and defines the minimum standards for both plumbed (potable) and self-contained systems.

In the final rule, employers must provide employees with an emergency eyewash, shower equipment,

or both to decontaminate themselves, based on the hazard. Eyewash and shower equipment

requirements apply both to all chemical substances that may be present in the workplace and, for

pesticide products, based on what the pesticide label requires.

Decontamination equipment is no longer linked to its location at a fixed or mobile site but is related to

the hazard.

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Historical Notes

Div. 4 - 21

Historical Notes

Based on comments received, Oregon OSHA is delaying the effective date to January 1, 2011, for all

changes in this rulemaking.

This is Oregon OSHA Administrative Order 4-2010, adopted July 8, 2010 and effective January

1, 2011.

Note 23: This rulemaking is to keep Oregon OSHA in harmony with recent changes to Federal

OSHA’s standards.

Oregon OSHA adopted changes to rules in general industry, construction, agriculture, and maritime.

Federal OSHA published a number of rule changes in these industries in the June 8, 2011 Federal

Register. This is Phase III of the Standards Improvement Project (SIP III), the third in a series of

rulemaking by Federal OSHA to improve and streamline the standards. This removes or revises

individual requirements within rules that are confusing, outdated, duplicative, or inconsistent.

Oregon OSHA adopted the majority of the federal changes that include:

• Personal Protective Equipment – Division 2/I, remove requirements that employers

prepare and maintain written training certification records.

• Respiratory Protection – revise requirements for breathing-gas containers.

• Material Handling/Slings – revise standards in general industry, construction, and maritime

standards.

• Commercial Division Operations – Division 2/T, remove two obsolete recordkeeping

requirements.

• General industry and construction – remove requirements in numerous standards for

employers to transfer specific records to the National Institute for Occupational Safety and

Health (NIOSH).

• Lead – amend trigger levels in general industry and construction.

In connection with rule changes in the SIP III rulemaking process, Oregon OSHA adopted additional

changes to the subdivisions and rules opened during this rulemaking activity. We also made reference

changes to Underground Installations in Division 3/P.

Oregon OSHA repealed all of Division 2/I rules with the exception of 1910.134 Respiratory Protection,

1910.137 Electrical Protective Equipment, 437-002-0138 Additional Oregon Rule for Electrical

Protective Equipment, 437-002-0139 Working Underway on Water, and 437-002-1139 Working Over

or In Water.

To replace them, we adopted new Oregon-initiated rule, 437-002-0134 Personal Protective

Equipment, that includes sections covering scope/application, hazard assessment, equipment,

training, payment, fall protection, clothing, high visibility garments, eye, head, foot, leg, hand and skin

protection.

The change in format simplifies the existing text while making little change to the overall rule

requirements with the following exceptions:

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Historical Notes

Div. 4 - 22

Historical Notes

• Modifies the hazard assessment requirement to clarify that employers must identify

hazards to the entire body, including the torso and extremities, when performing the

assessment. The assessment is currently limited to head, hands, eyes and face and foot

protection. Note: The assessment for eyes, face, head, hands, and feet are currently in

effect. The torso and extremities (e.g. arms and legs) element of the body assessment will

not be enforced until July 1, 2012.

• Change the fall protection component criteria to align with the systems criteria found in

1926.502 of the construction standards. The training requirement in this rule would also

cover those parts not previously covered, such as fall protection.

Definition of “potable water”:

Previously, Oregon OSHA did not adopt 1910.141(a)(1), so the SIP-III changes to the definition of

potable water must be addressed through Oregon-initiated rules. We will maintain the current

definition of potable water in Division 2/J, 437-002-0141(1)(a), Sanitation and Division 4/J, 437-004-

1105(1)(b), Sanitation. However, for consistency, we changed the definition of potable water in

Division 4/J, 437-004-1110, Field Sanitation for Hand Labor Work, and Division 3/D, 437-003-0015

Drinking Water to the same definition.

MOCA -- 4,4’-Methylene bis (2-chloroaniline):

As a logical extension of the Federal OSHA SIP-III changes to 29 CFR 1910.1003, 13 Carcinogens,

we amended the Oregon Rules for MOCA (4,4’-Methylene bis (2-chloroaniline)) at Division 2/Z, 437-

002-0364. The requirements for respiratory protection are updated and the requirements for transfer

of records is simplified. Most transfer of medical records to NIOSH is eliminated with the SIP III

rulemaking. The employer is required to follow the requirements of the Respiratory Protection rule and

select appropriate respirators based on the selection criteria in 1910.134(d). (The type of respirator to

use is no longer specified.) We will also remove and reserve 437-002-0364(6)(a) which had a

reporting requirement end date of December 1974.

This is Oregon OSHA Administrative Order 4-2011, adopted and effective December 8, 2011.

Note 24: Oregon OSHA proposed changes to Agriculture, Division 4/A General Subjects; 4/B

Definitions; 4/I Protective Equipment; and 4/Z Chemical/Toxins. We removed subdivisions A and B

from this current rulemaking action. Three public hearings were held in June 2012 with no comments

received for proposed changes to subdivisions I and Z. Oregon OSHA adopts one new rule in Division

4/Z, one new appendix in Division 4/I, and amends 23 existing rules in Division 4/I and 4/Z.

Subdivision I modifies the requirements for employers providing Personal Protective Equipment to

include an evaluation of the hazards. A new non-mandatory appendix to Subdivision I provides a

template for employers to use in this evaluation. Also, training requirements are specified for

employees using general PPE. The format of the rules for PPE for parts of the body (head, eyes and

face, hands and feet) is simplified and the requirements are aligned with the requirements in the

Division 2 rules.

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Historical Notes

Div. 4 - 23

Historical Notes

The format is standardized in the rules for Subdivision Z (Chemicals and Toxins.) The Division 4 Air

Contaminant rules are updated to match the Division 2 Air Contaminant rules. The substance-specific

rules make clear that either the Division 2 or Division 3 rules apply, depending on the type of activity,

if there is an exposure to these toxins.

This is Oregon OSHA Administrative Order 4-2012, adopted September 19, 2012, and effective

January 1, 2013.

Note 25: Oregon OSHA has adopted changes related to the globally harmonized system of chemical

classification and labeling (GHS) into OAR 437-004-9800, the Hazard Communication Standard

(HCS) for Agricultural Employers. In addition, twelve related Division 4 rules were modified to

incorporate the GHS definitions and terminology.

The related rules include the Division 4 universal definitions; and standards for flammable liquids, fire

prevention, pipe labeling, and the storage of hazardous chemicals.

This rulemaking will improve safety for agricultural workplaces by focusing on the hazard

communication requirements pertaining to users of hazardous chemicals (as opposed to those for

manufacturers, importers, and distributors.) These revisions will simplify compliance by establishing a

uniform flow of information about chemical hazards in Oregon OSHA’s Division 4 rules.

This is Oregon OSHA Administrative Order 3-2014, adopted and effective August 8, 2014.

Note 26: Oregon Occupational Safety and Health Division (Oregon OSHA) administers and enforces

the employee safety and health part of the U.S. Environmental Protection Agency (EPA)’s pesticide

Worker Protection Standard (WPS) as adopted in Division 4/ Agriculture as adopted at OAR 437-004-

6000. The standard aims to protect workers – those who work in pesticide-treated crop areas – and

handlers – those who mix, load, and apply pesticides. EPA modified the WPS at the federal level (40

CFR 170) in the November 2, 2015 Federal Register. In response, Oregon OSHA initiated the rule-

making process working with an advisory committee – including representatives of labor, employers,

grower organizations, and government and nonprofit agencies, and other stakeholders – and

reviewed extensive public comments received both orally at three public hearings held around the

state, and in written format following formal proposal in late 2016.

Oregon OSHA is adopting most of the modified rules initiated by the EPA as well as several Oregon-

initiated rules introduced to reflect the unique circumstances for employers in Oregon. The agency will

continue to enforce the existing WPS through the end of 2017.

The rule changes are expected to lead to an overall reduction in incidents of unsafe pesticide

exposure and to improve the occupational health of agricultural workers and pesticide handlers.

The adopted OARs:

• 437-004-6001 gives expiration and implementation dates for the existing and revised rules.

The rules codified in Division 4/W as 170.1 through 170.260 will remain in effect through

2017, and expire on 12/31/2017. The new rules, codified as 170.301 through 170.607, and

the other five new OARs will be implemented beginning on January 1, 2018.

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Historical Notes

Div. 4 - 24

Historical Notes

• 437-004-6401 and 437-004-6501 provide specific effective dates for the revised subject

matter to be included in training programs for both workers and handlers. In addition, the

requirements for crop advisor training programs necessary to exempt workers and

handlers from WPS training is cross-referenced to the minimum subject matter in these

OARs.

• 437-004-6508 Respiratory Protection and 437-004-6509 Emergency eye-washes and eye

flushing supplies maintain Oregon OSHA’s more protective requirements related to

respiratory protection and emergency eye-washes while fulfilling the EPA’s pesticide label

requirements.

• 437-004-6502 augments training requirements in Oregon for trainers of WPS handlers who

use the Train-the-Trainer qualification described in 170.501(c)(4)(ii) of the WPS. The

adopted rule does not apply to trainers of WPS handlers who meet the qualification as

certified applicators described in 170.501(c)(4)(iii).

The agency will reconsider some details of the 2016 WPS proposal through a separate public

rulemaking process centered on the Application Exclusion Zone (AEZ.) To give more time to fine-tune

those provisions and to ease the transition to the modified rule requirements, Oregon OSHA is

delaying implementation of the modified standard until Jan. 1, 2018. The expected result will be a

revised proposal initiated in 2017, in time for it to take effect with the other modified sections of the

WPS on Jan. 1, 2018.

This is Oregon OSHA Administrative Order 1-2017, adopted February 14, 2017 and effective

January 1, 2018.

Note 27: Oregon OSHA administers and enforces the Environmental Protection Agency’s (EPA)

pesticide Worker Protection Standard (WPS) as adopted in Division 4/W (Agriculture/Worker

Protection Standard), OAR 437-004-6000. Oregon OSHA has adopted two new Oregon

Administrative Rules (OARs) that reflect specific requirements for employers in Oregon.

These rules complement and complete the changes adopted by Oregon OSHA on February 14th,

2017 on the amended Worker Protection Standard adopted by the EPA in the November 2, 2015

Federal Register. The rules, which exceed federal requirements, take effect January 1 ,2019.

The new OARs:

OAR 437-004-6405:

Restrictions associated with outdoor production pesticide applications(which replaces 170.405(a), is a

new rule that describes the Application Exclusion Zone requirements (AEZ) including how employers

ensure enclosed agricultural structures are closed properly, must provide instruction and information,

and a decision matrix that navigates the rule requirements.

OAR 437-004-6406:

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Historical Notes

Div. 4 - 25

Historical Notes

Pesticide spray drift and innovative methods is a new rule that describes that if issues relating to

spray drift occur, then the employer is responsible for addressing those issues, and how drift

reduction technologies can be used to gain approval for innovative methods through the variance

process.

The WPS rules are also referenced, in Division 2, General Industry, at OAR 437-002-0170; and in

Division 7, Forest Activities, at OAR 437-007-0010.

Pesticides, although a clear necessity in many workplaces, also represent varying levels of risks to

workers and others (depending on both the particular pesticide used and the circumstances of the

application). The Worker Protection Standard, taken as a whole, provides a number of important

protective measures to reduce those risks. However, the risk of unintended exposures due to what is

typically referred to as unintended “drift” can create exposure to workers outside the intended

application area. In the case of worker housing, that exposure can also involve the workers’ family

members. The provisions of this proposed rule – as was true of the original EPA rule addressing

AEZs – are intended to address that potential by providing an added measure of protection against

unintended and unanticipated exposures outside of the locations where pesticides are intended to be

applied. The AEZ surrounds and moves with spray equipment, beyond the safeguards enforced with

respect to the treated area, must be free of all people other than appropriately trained and equipped

pesticide handlers. The rule changes are expected to lead to an overall reduction in incidents of

unsafe pesticide exposure and to improve the occupational health of agricultural workers and

pesticide handlers.

Oregon OSHA held five hearings in multiple locations on these proposed rules. The division received

938 written comments during the extended comment period and over 100 oral comments at these

hearings. These comments were vast and diverse, and all were considered by Oregon OSHA before

the division adopted the rules as filed. Oregon OSHA published a summary of comments and agency

decisions document on its website for viewing.

This is Oregon OSHA Administrative Order 2-2018, adopted June 29, 2018 and effective January

1, 2019.

Note 28: This rulemaking is to keep Oregon OSHA in harmony with recent changes to federal

OSHA’s standards.

On September 26, 2019, federal OSHA adopted final rules for adding two additional PortaCount®

quantitative fit testing protocols to its Respiratory Protection Standard (29 CFR 1910.134, Appendix

A). These new protocols are: the modified ambient aerosol condensation nuclei counter (MCNC)

quantitative fit testing protocol for full-facepiece and half-mask elastomeric respirators (MCNC-ER);

and the modified ambient aerosol condensation nuclei counter quantitative fit testing protocol for

filtering facepiece respirators (MCNC-FFR). Both protocols (MCNC-ER and MCNC-FFR), are

abbreviated variations of the current federal OSHA-accepted ambient aerosol condensation nuclei

counter (CNC) quantitative fit testing protocol (also referred to as the PortaCount® protocol).

However, both new protocols differ from the original PortaCount® method by exercise sets, exercise

durations, and sampling sequence.

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Historical Notes

Div. 4 - 26

Historical Notes

For Oregon OSHA’s rulemaking purposes, these protocols will serve as alternatives to the four

existing quantitative fit testing protocols already listed in Appendix A of the Respiratory Protection

Standard and will maintain safety and health protections for workers while providing additional

flexibility and reducing compliance burdens for employers. Appendix A in the Respiratory Protection

Standard (29 CFR 1910.134) and Appendix A in OAR 437-004-1041 (Oregon OSHA’s agriculture

respiratory protection standard), are amended to include both the MCNC-ER and MCNC-FFR

protocols. These protocols cover and will be available to employers in general industry, construction,

and agriculture (through amendment of 437-004-1041 to include these additions).

Oregon OSHA also adopted the addition of the controlled negative pressure (CNP) REDON

quantitative fit testing protocol to Appendix A of OAR 437-004-1041. The Respiratory Protection

Standard (29 CFR 1910.134) already has the CNP REDON protocol listed as an option to general

industry and construction employers. This will improve compliance homogeneity between the

Respiratory Protection Standard (29 CFR 1910.134) and OAR 437-004-1041, and provide each

employer group with the same quantitative fit testing protocol options.

One hearing was held on January, 7, 2020, at the Oregon OSHA Salem Field Office. There were no

public comments given at the hearing. The agency received two public comments during the comment

period, and at the end of the comment period decided to adopt the rulemaking changes as proposed.

This is Oregon OSHA Administrative Order 1-2020 adopted and effective February 13, 2020.

Note 29: This rule is needed to protect vulnerable workers in employer-provided labor housing from

the health risks created by the current COVID-19 public health emergency, especially those who

spend both their working and their off-work hours at the employer’s location. Oregon OSHA's

temporary rule: COVID-19 Public Health Emergency in Labor Housing and Agricultural Employment

(OAR 437-001-0749) expired on October 24, 2020. On October 23, 2020, Governor Brown issued an

Executive Order 20-58 extending employer-provided housing requirements (Section 2) of OAR 437-

001-0749. As the Governor’s Executive Order is set to expire, the public health emergency remains a

substantial concern in Oregon. As a result, it is necessary to extend the provisions from the Executive

Order with a permanent rule. The exposures created in the labor housing environment, particularly in

working situations requiring large numbers of workers, make these rules necessary to reduce risk to

individual workers. Many workers face unique challenges in situations where housing is provided as

part of the employment relationship. In consultation with stakeholders, Oregon OSHA modified some

requirements from the temporary rule in the proposed rule given more information concerning COVID-

19 transmission. Oregon OSHA indicated in the proposed rule that it will repeal this rule once it is no

longer necessary to address the COVID-19 pandemic in employer-provided labor housing.

Three public hearings were held in March 2021 where Oregon OSHA received oral testimony on the

proposed rule. The agency also received written comments on the rule from agricultural producers,

employer representatives and farmworker advocacy organizations. Generally, feedback from

advocacy organizations centered on ventilation, physical distancing, and sleeping density

requirements. Most employer feedback focused on the definition of household, sleeping density,

specifying an end date, and sanitation as well as questions about vaccination.

Agriculture

4

Oregon Occupational Safety and Health Division Oregon Administrative Rules AO 2-2023 Division 4

Historical Notes

Div. 4 - 27

Historical Notes

Oregon OSHA, based on the comments received, made adjustments to the proposed OAR 437-004-

1115. Notable changes to the proposed rule include a change to the definition of household and

timeframe for repeal.

This is Oregon OSHA Administrative Order 1-2021, adopted and effective April 30, 2021.

4

Agriculture

Division 4 AO 2-2023 Oregon Administrative Rules Oregon Occupational Safety and Health Division

Historical Notes

Div. 4 - 28

Historical Notes

Oregon Administrative Rules

Oregon Occupational Safety

and Health Division

APPLICATION / SCOPE

A

437-004-0001 A-1 437-004-0002

437-004-0001 Application.

Everything in this standard is the responsibility of the employer. It is the responsibility of the

employer to assure that their workers, facilities and equipment comply with this standard.

Stat. Auth.: ORS 654.025(2) and 656.726(4).

Stats. Implemented: ORS 654.001 through 654.295.

Hist: OR-OSHA Admin. Order 4-1998, f/8/28/98, ef. 10/1/98.

437-004-0002 Scope.

Standard Industrial Classifications – Division 004, Agriculture, applies only to employers

with the following Standard Industrial Classifications (SIC) or North American Industrial

Classification system (NAICS) codes.

NOTE: If you don’t know your code, contact your Workers’ Compensation Insurance carrier.

SIC NAICS

01 111 All Groups

02 112 All Groups

0711 115112 Soil Preparation Services

0721 115112 Crop Planting, Cultivating, and Protection

0722 115113 Crop Harvesting, Primarily by Machine