Tire Care

& Safety

Pressure

Tread Depth

Rotation

1

BASIC TIRE INFORMATION

3 Proper Tire Size, Type and Load Capacity (or Load Range)

3 Tire Size Designations

5 The Sidewall Story

8 Speed Symbol

9 Uniform Tire Quality Grading (UTQG) Standards

10 Tire Registration and Recall Information

PROPER TIRE INFLATION AND VEHICLE LOADING

11 Proper Inflation is Critical

13 When to Check Inflation Pressure

13 Continuous Inflation Pressure Loss

14 Additional Tire Pressure Recommendations

15 Proper Tire Loading

REGULAR TIRE ROTATION

16 Rotation Patterns

REGULAR TIRE INSPECTION

18 Tire Inspection Guidelines

20 Tire Service Life

PROPER TIRE REPAIR

21 Have Your Tire Repaired Properly

23 Vehicle Original Equipment Temporary Tire Mobility Kits

23 Aftermarket Sealants

VEHICLE CONDITION, ALIGNMENT AND MAINTENANCE

24 Maintenance Conditions

25 Additional Conditions Affecting Tread Wear

26 Spare Tire Maintenance

26 Tire Storage Recommendations

27 Cleaning Tires

GOOD DRIVING HABITS

28 Road Hazard and Impact Damage

28 Sudden Vibration or Ride Disturbance

28 Tire Spinning

29 Wet Weather Driving

29 Winter/Snow Conditions

TIRE REPLACEMENT GUIDELINES

32 The Right Tire for the Vehicle

33 Self-Supporting Runflat Tires

33 Tire Mixing

34 Replacing Less Than Four Tires

34 Used Tires

TABLE OF CONTENTS

2

This booklet provides an understanding of the many factors essential to the

proper care and service of passenger and light truck tires. This booklet is not

all inclusive. Questions pertaining to specific products and/or vehicle fitments

should be addressed to the vehicle manufacturer, tire manufacturer or tire

dealer.

TIRE INFORMATION AND SERVICE ASSISTANCE

When you have a question about tires, there are various sources

of information available. The U.S. Tire Manufacturers Association’s

website, www.USTires.org, provides information on tire care and safety

and publications for consumers. The National Highway Traffic Safety

Administration’s website, www.safercar.gov has a wide range of tire related

information including information on tire labeling, tire ratings, and tire

maintenance. Also, tire manufacturer’s and tire retailer’s websites will often

contain a considerable amount of helpful tire information.

The Most Important Factors in Tire Safety, Performance and Service Life are:

• Proper Tire Size, Type and Load Capacity (or Load Range)

• Proper Inflation Pressure

• Proper Vehicle Loading

• Regular Tire Rotation

• Regular Inspection

• Proper Tire Repair

• Vehicle Condition, Alignment and Maintenance

• Good Driving Habits

Your local tire retailer, who has specialized tire knowledge and experience, is

an excellent resource when you have a question about tires or require service

assistance. Tire service professionals can provide you with proper tire service

including inspection, replacement and repair.

Tire Care and Safety

3

Note: Pickups, vans, sport ulity vehicles, and other vehicles that might be

perceived as a “light truck” are oen equipped with P-Metric and Metric re

sizes. Check the vehicle re placard to see which type of re is specied for

the vehicle.

BASIC TIRE INFORMATION

Proper Tire Size, Type and Load Capacity (or Load Range)

There are a large number of tires for passenger cars and light trucks intended

to meet the needs of a wide variety of consumers, vehicles and operating

conditions. Selecting and utilizing the proper tire starts with an understanding

of the basics of tire size, type and load capacity (or load range), which is

presented in this section. In addition, there is an explanation of speed ratings,

determining a tire manufacture date and a guide to other information found

on the sidewalls of most passenger and/or light truck tires.

Tire Size Designations

Most passenger and light truck tires have tire size designations such as the

following:

Passenger

4

Tire Size Designations Continued

Light Truck

LIGHT TRUCK

Aspect Ratio - In a tire size designation, the aspect ratio is the ratio of the tire

section height to section width. Aspect ratios are also referred to as “series”

and “profile” numbers. In the example shown of a tire with an aspect ratio of

60, the section height of the tire is 60% of the section width. Aspect ratios

typically range from 30 to 80.

5

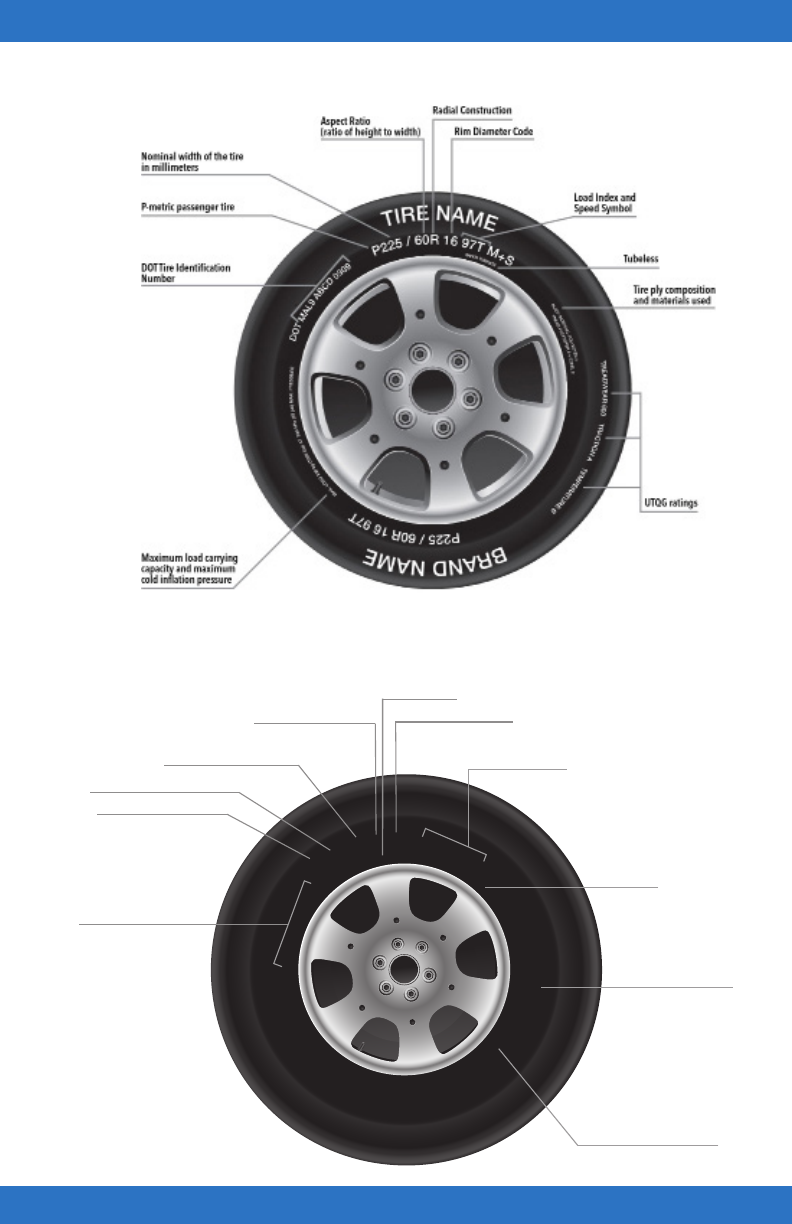

The Sidewall Story

Tires have very useful information molded onto their sidewall. It shows the

brand and model name of the tire, its size, whether it is tubeless or tube type,

the maximum load and the maximum inflation, safety warning(s), and much

more.

P225/60R16 97T – (See Passenger Tire on page 6) Size marking and service

description (load index and speed symbol) for a P-Metric speed-rated

passenger tire.

LT245/75R16 120/116Q Load Range E – (See Light Truck Tire on page 6) Size

marking, service description (load index and speed symbol) and load range for

a metric light truck tire. The load range identifies the tire’s load and inflation

limits.

Load Index - The load index is a numerical code associated with the maximum

load a tire can carry. The load index should not be used independently to

determine replacement tire acceptability for load capacity. (See page 32 for

replacement tire guidelines.)

Speed Symbol - The speed symbol is also known as a “speed rating.” See page 8.

Max Load 730 kg (1609 lbs) at 300 kPa (44 psi) Max Pressure -

(See Passenger Tire on page 6) indicates maximum load and maximum cold

inflation pressure of the tire. Sidewall markings are given in both metric and

English units. Follow tire inflation pressure recommendations on the vehicle

tire placard, certification label or in the owner’s manual.

Max Load Single 1380 kg (3042 lbs) at 550 kPa (80 psi) Cold

Max Load Dual 1260 kg (2778 lbs) at 550 kPa (80 psi) Cold -

(See Light Truck Tire on page 6) indicates the maximum load of the tire and

corresponding maximum cold inflation pressure for that load when used in a

single or dual configuration. Sidewall markings are given in both metric and

English units. Follow tire inflation pressure recommendations on the vehicle

tire placard, certification label or in the owner’s manual.

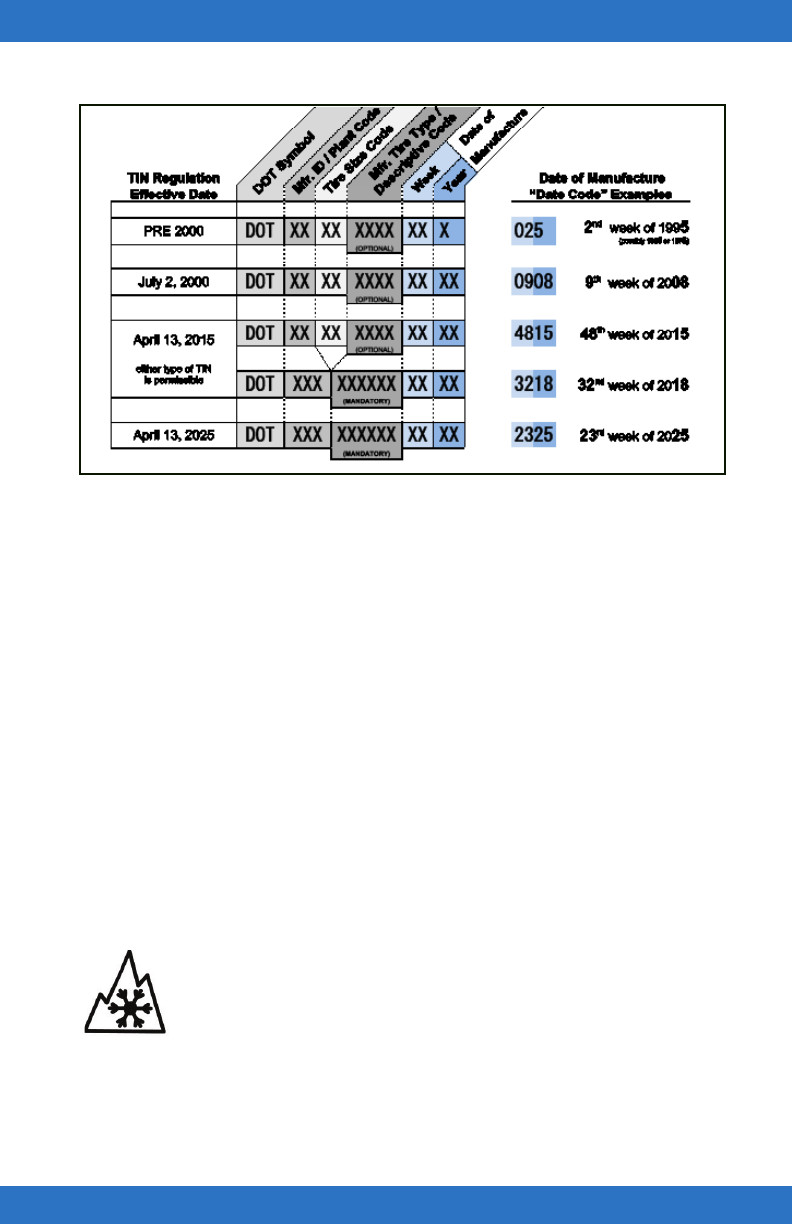

DOT MA L9 ABCD 0309 - The “DOT” symbol certifies the tire manufacturer’s

compliance with U.S. Department of Transportation (U.S. DOT) tire safety

performance standards. Next to these letters is the tire identification number

(TIN) - also known as the tire “serial” number. Since the year 2000, the last four

digits are numbers identifying the week and year of manufacture (Example:

“0309” means third week of the year 2009.)

Over the years and in the future, the TIN found on the tire may be different.

6

Light Truck Tire

L

T

2

4

5

/

7

5

R

1

6

1

2

0

/

1

1

6

Q

M

+

S

D

O

T

M

A

L

9

A

B

C

D

0

3

0

9

M

A

X

.

L

O

A

D

S

I

N

G

L

E

1

3

8

0

k

g

(

3

0

4

2

)

A

N

D

5

5

0

k

P

a

(

8

0

p

s

i

)

M

A

X

.

P

R

E

S

S

.

C

O

L

D

M

A

X

.

L

O

A

D

D

U

A

L

1

2

6

0

K

G

(

2

7

7

8

l

b

s

)

A

T

5

5

0

k

P

a

(

8

0

p

s

i

)

M

A

X

P

R

E

S

S

.

C

O

L

D

L

O

A

D

R

A

N

G

E

E

R

A

D

I

A

L

T

U

B

E

L

E

S

S

Light truck tire

Nominal width of the tire

in millimeters

Aspect Ratio

(ratio of height to width)

Radial Construction

Rim Diameter Code

Load Range

Load Index

(single/dual) and

Speed Symbol

Maximum load carrying

capacity at maximum

cold inflation pressure

(single and dual load)

T

I

R

E

N

A

M

E

P

L

I

E

S

:

S

I

D

E

W

A

L

L

P

O

L

Y

E

S

T

E

R

2

T

R

E

A

D

P

O

L

Y

E

S

T

E

R

2

+

S

T

E

E

L

2

+

N

Y

L

O

N

1

DOT Tire Identification

Number

Tire ply composition

and material used

B

R

A

N

D

N

A

M

E

Tubeless

Passenger Tire

7

DOT TIN Description

TREADWEAR 600 TRACTION A TEMPERATURE B – Treadwear, traction,

and temperature are quality grades established and required by U.S. DOT

under the Uniform Tire Quality Grading Standards (UTQG). See page 9.

Plies/Fabric Information - The ply/fabric information identifies the number

of plies and type of cord materials in the tire tread and sidewall areas.

Radial - A tire with a radial construction must show the word “RADIAL” on

the sidewall. A radial tire is also indicated by the character “R” in the size

designation.

Tubeless - The tire must be marked either “tubeless” or “tube type.”

M + S - This mark is commonly found on all-season and winter tires. In

several formats, the letters “M” and “S” indicate the tire is intended for

limited mud and snow service. Other formats include: “MS,” “M/S,” or

“M&S.”

Mountain Snowflake Symbol - This mark is found on winter/snow tires that

meet the USTMA definition for passenger and light truck tires

for use in severe snow conditions. These tires are marked on at

least one sidewall with the letters “M” and “S” plus a mountain/

snowflake pictograph.

8

M M 81 130

N N 87 140

P P 93 150

Q Q 99 160

R R 106 170

S S 112 180

T T 118 190

U U 124 200

H H 130 210

V V 149 240

W W 168 270

Y Y 186 300

(Y) -- >186 >300

* In standardized laboratory tests that relate to highway speeds. Actual tire speed and performance

capability depend on factors such as inflation pressure, load, tire condition, wear, and driving conditions.

** Any tire having a maximum speed capability above 149 mph (240 km/h) may, at the tire man-

ufacturer’s discretion, include a “Z” in the size designation (i.e. P275/40ZR17). For tires having a

maximum speed capability above 186 mph (300 km/h), a “Z” must appear in the size designation

and must include a service description with a “(Y).”

Consult the tire manufacturer for speed capability when there is no service description or speed

symbol marked on the tire.

Examples:

P275/40ZR17 max speed > 149 mph - consult tire mfr.

P275/40R17 93W max speed = 168 mph

P275/40ZR17 93W max speed = 168 mph

P275/40ZR17 93Y max speed = 186 mph

P275/40ZR17 (93Y) max speed > 186 mph - consult tire mfr.

Speed Symbols

Speed

Symbol

Speed

Rating

Speed Category*

MPH KM/H

Speed Symbol

The speed symbol, also known as a speed rating, indicates the speed category

associated with the tire’s maximum speed capability. Speed ratings are

based on laboratory tests that relate to performance on the road, but are

not applicable if tires are under inflated, over loaded, worn out, damaged, or

altered.

Although a tire may be speed rated, USTMA does not endorse the operation

of any vehicle in an unsafe or unlawful manner. Furthermore, tire speed

ratings do not imply that a vehicle can be safely driven at the maximum

speed for which the tire is rated, particularly under adverse road and weather

conditions or if the vehicle has unusual characteristics. Consult the tire

manufacturer for speed capability when there is no service description or

speed symbol marked on the tire.

ZR**

9

Uniform Tire Quality Grading (UTQG) Standards

The National Highway Traffic Safety Administration (NHTSA) established

the Uniform Tire Quality Grading Standards as a way to assist the consumer

to compare various tires. UTQG applies to the vast majority of passenger

car tires (excluding tires such as winter-type snow tires). NHTSA sets the

standards that rate the relative performance of tires based on three criteria:

treadwear, traction and temperature. The grades are molded on the tire

sidewall. Replacement tires also have a label affixed to the tread that lists and

explains these grades. A vehicle’s engine type, transmission type, gear ratios,

driving styles, road surface, inflation pressure, and other factors can affect

actual performance of the tire from one vehicle to another.

The UTQG tire characteristics are as follows:

TREADWEAR - The TREADWEAR grade is a comparative rating based on the

wear rate of the tire when tested under controlled conditions on a specified

government test course. In the example shown, the TREADWEAR grade is

600, which means it would wear twice as well on the government course

as a tire graded 300. The relative performance of tires depends upon the

actual conditions of their use and may depart significantly from the norm

due to variations in driving habits, service practices and differences in road

characteristics and climate.

TRACTION - The TRACTION grades, from highest to lowest, are AA, A,

B, and C and they represent the tire’s ability to stop on wet pavement as

measured under controlled conditions on specified government test surfaces

of asphalt and concrete. The TRACTION grade assigned is based on braking

(straight ahead) traction tests and does not include cornering (turning)

traction.

TEMPERATURE - The TEMPERATURE grades are A (the highest), B and C,

representing the tire’s resistance to the generation of heat and its ability to

dissipate heat when tested under controlled conditions on a specified indoor

laboratory test wheel. The TEMPERATURE grade is established for a tire that

is properly inflated and not over loaded. Excessive speed, under inflation,

or over loading, either separately or in combination, can cause heat buildup

which may result in tire damage and/or tire failure.

In addition to the UTQG standards, all passenger car tires must conform to

federal performance safety requirements.

UTQG Tire Marking Example

10

Tire Registration and Recall Information

Registraon of res is an important step to complete when placing them into

service. Registraon enables manufacturers to contact the consumer in the

event of a recall. At the point of sale, consumers should be provided a re

registraon card. This informaon should be completed and submied as

soon as possible. USTMA re manufacturer members also provide online re

registraon forms that can be submied electronically.

Consumer contact informaon and DOT Tire Idencaon Numbers (TIN) are

necessary for registraon. In addion, DOT TINs are necessary to determine

whether a re is subject to a recall. Visit www.USTires.org for links to USTMA

member re registraon websites and for a re recall lookup tool.

11

PROPER TIRE INFLATION AND VEHICLE LOADING

The recommended inflation pressures for tires are specified in PSI (pounds

per square inch) or kPa (kilopascals) as indicated on the vehicle tire placard,

certification label or in the owner’s manual. Never set tire inflation pressures

below the recommended inflation pressure found on the vehicle tire placard,

certification label or owner’s manual. Under inflation causes excessive heat

build-up and internal structural damage that may lead to a tire failure, including

tread/belt separation, even at a later date. Do not exceed the maximum

inflation pressure shown on the tire sidewall. Over inflated tires (over the

maximum molded on the tire sidewall) are more likely to be cut, punctured or

damaged by sudden impact from hitting an obstacle, such as a pothole.

Example of a Vehicle Tire Placard Example of a Vehicle Certification Label

Proper Inflation is Critical

Inflation pressure enables a tire to support the load and to control the vehicle,

therefore proper inflation is critical. With the right amount of inflation

pressure, the vehicle and the tires will achieve their optimum performance.

In addition to tire safety, this means your tires will wear longer and improve

vehicle fuel consumption. Note that some vehicles may have different cold

inflation pressures for tires on the front and rear axles.

Driving on tires with improper inflation pressure is dangerous.

• Under inflation causes excessive heat build-up and internal structure

damage.

• Over inflation makes it more likely for tires to be cut, punctured or broken

by sudden impact.

These situations can cause a tire failure, including tread/belt separation, even at

a later date, which could lead to an accident and serious personal injury or death.

Consult the vehicle tire placard, certification label or the owner’s manual for the

recommended inflation pressures.

12

It is impossible to determine whether radial tires are properly inflated just

by looking at them. You must use a tire gauge to properly check the inflation

pressure. Motorists should have their own gauge and keep it in the vehicle.

One of these tires is dangerously under inflated. You cannot tell just by

looking.

Properly Inflated 50% Under Inflated

Check inflation pressure with an accurate tire gauge. A gauge calibrated in

1 psi increments up to 60 psi is sufficient for most passenger tires. A dual

head gauge calibrated in 2 psi increments up to 100 psi is sufficient for light

truck tires. Even if it is difficult to check the inflation pressures of inside tires

in dual fitments, it is imperative that these inflation pressures be checked

and properly maintained because the inside dual tires are subjected to more

severe operating conditions, such as:

• High heat exposure, due to close proximity to brakes

• Lower air circulation to assist in cooling

• Crowned road surfaces (which can cause inside dual tires to support

more of the load than the outside dual tires)

Mechanical and Digital Style Gauges

NOTE

The pressure indicated on the tire sidewall is the maximum allowed in the tire,

irrespective of the vehicle. Follow the vehicle manufacturer’s recommendations for

inflation pressure found on the vehicle tire placard, certification label or in the owner’s

manual.

13

When to Check Inflation Pressure

Check inflation pressure when tires are cold, that is, when the vehicle has

been parked for at least 3 hours or has been driven less than one mile at

moderate speed. The inflation pressure in all tires, including the spare tire

and inside duals, should be checked with an accurate tire gauge at least

once a month. Additional checks should be made before long trips, carrying

heavy loads, towing a trailer and any time high speeds are anticipated. This

includes vehicles equipped with a Tire Pressure Monitoring System (TPMS).

Maintaining proper inflation pressure maximizes fuel economy and optimizes

overall tire performance.

Never “bleed” or reduce inflation pressure when tires are hot from driving, as

it is normal for pressures to increase above recommended cold pressures. If a

hot tire pressure reading is at or below recommended cold inflation pressure,

it may be dangerously under inflated. In this case, immediately determine the

cause and/or have the tire checked by a tire service professional.

Passenger and light truck tires may lose 1 to 2 psi inflation pressure per

month under normal conditions and 1 to 2 psi for every 10 degrees F

temperature drop. If a tire continually loses more than 2 psi per month, have

it checked by a tire service professional. Significant changes in altitude or

temperature will result in changes in inflation pressure and will require an

adjustment.

Continuous Inflation Pressure Loss

Any tire that continually requires re-inflation is a serious safety risk. The

cause may be a puncture, road hazard damage, leaking valve, corroded or

damaged rim, tire mounting damage or other irregular condition. Continuous

use of a tire in an under inflated condition will result in heat build-up and

internal tire damage. This may result in a tire failure, including tread/belt

separation. Tires that continuously require re-inflation should be inspected

thoroughly by a tire service professional and be properly serviced or replaced

immediately.

Inflating an unsecured tire is dangerous. If it bursts, it could be hurled into the

air with explosive force resulting in serious personal injury or death.

Never inflate a tire unless it is secured to a vehicle, tire mounting machine or

other restraining device.

14

Additional Tire Pressure Recommendations

Dual Tire Assemblies - For vehicles equipped with dual tire assemblies (duals),

if one of the dual tires becomes significantly under inflated or flat, the other

tire will carry the load for both tires, resulting in an over loaded condition for

both tires. Both tires should be inspected by a tire service professional for

damage.

Tire Pressure Monitoring Systems (TPMS) - It is still important to check

inflation pressure at least once a month, even on vehicles that are equipped

with a TPMS. Tire pressure monitoring systems are designed to be beneficial

and accurate. However, a TPMS should not be solely relied on for inflation

pressure maintenance since some systems may have limitations, such as:

• Lack of warning of low inflation pressure until one or more tires are as

much as 25% below the vehicle manufacturer recommendations.

• May only detect inflation pressure differences between tires (in other

words, if all tires are losing inflation pressure at the same rate, it is

possible that the TPMS will not adequately warn of inflation pressure

loss).

• May not warn of rapid inflation pressure loss in a single tire.

Under inflation (prior to a TPMS warning) is increasingly dangerous at

high speeds, heavy vehicle loads, extended distances and at high ambient

temperatures.

Spare Tire Inflation Pressure - Full-size and temporary spare tire inflation

pressure should be checked monthly and before any long trips. Use an

accurate gauge. T-type temporary spare tires require 60 psi (420 kPa). When

adjusting inflation pressure in T-type tires, do so in small amounts since the

tire is smaller and the pressure level changes rapidly. Do not over inflate.

Valve Caps - Always cover the valve stem with a sealing cap. This helps

prevent moisture, dirt and other contaminants from entering the valve core,

as well as providing an additional seal.

Inflation Pressure for Off-Road Use - Inflation pressures for tires used in

most off-road situations should be the same as those for highway driving. If

a lower inflation pressure is used to gain additional flotation/traction at low

speeds, tires must be re-inflated before resuming driving on the highway or at

higher speeds, whether on- or off- road.

Using Nitrogen Inflation - Nitrogen may be offered as an alternative to air

for tire inflation. Nitrogen is an inert (non-flammable) gas - basically, nothing

more than dry air with oxygen removed (air contains about 78% nitrogen).

15

For normal tire service applications, nitrogen inflation is not necessary.

However, nitrogen inflation is permissible as its properties may contribute

to minor reductions in inflation pressure loss. Nevertheless, several other

sources of pressure leaks, such as punctures, tire/rim interface (bead), valve,

valve/rim interface, and the wheel, may negate the benefit of nitrogen.

Nitrogen and air can be mixed in any and all proportions. Nitrogen filled tires

can and should have air added whenever nitrogen is not readily available, to

maintain proper inflation as specified by the vehicle manufacturer.

Proper Tire Loading

To avoid over loading tires, maintain the proper inflation pressure and never

exceed the vehicle’s load capacity, Gross Axle Weight Ratings (GAWR) or

the Gross Vehicle Weight Rating (GVWR) stated on the vehicle tire placard,

certification label or the owner’s manual. The vehicle load must also be

distributed so that no individual axle, tire or dual assembly is over loaded.

The maximum load for each tire

is molded on the tire sidewall

(along with the maximum

inflation pressure for that load).

Never exceed the maximum

limits on the tire or the rim/

wheel.

For improved fuel efficiency,

reduce vehicle weight as

much as possible by removing

unnecessary items from your

cargo storage areas (in addition

to keeping tires properly

inflated).

Consult your vehicle owner’s

manual for load recommenda-

tions and special instructions

(such as trailer towing).

Under inflation and/or over loading of a tire

causes excessive heat build-up and internal

structural damage. This may cause a tire

failure, including tread/belt separation,

even at a later date, which can lead to an

accident and serious personal injury or

death.

Over loading a vehicle can have other serious

safety consequences such as suspension or

wheel failure, increased braking distance or

brake failure (particularly on steep grades),

and adverse vehicle handling/stability.

Consult the vehicle tire placard,

certification label or owner’s manual for the

recommended vehicle load limits and tire

inflation pressures.

NOTE

Whether inflated with air or nitrogen, regular inflation pressure maintenance remains

critical and necessary. Use of nitrogen alone is not a replacement for regular inflation

pressure maintenance.

16

REGULAR TIRE ROTATION

Rotation Patterns

Tire rotation procedures are established to equalize the tread wear for each

tire to prolong tread life. By regularly changing a tire to another position on

the vehicle, any abnormal wear patterns that were starting to develop may be

corrected.

Before rotating tires, always consult the vehicle and/or tire manufacturer

for specific recommendations regarding rotation. If no rotation period is

specified, tires should be rotated every 5,000 to 8,000 miles or at any sign of

uneven wear. The first rotation is the most important. If tires show uneven

tread wear, check for and correct any misalignment, imbalance, or other

mechanical problems before rotation. Any vehicle showing a tendency for

wear differential should have tires rotated more often.

Many vehicle manufacturers recommend replacing all tires on the vehicle

at the same time. This makes rotation even more important for maintaining

uniform tread depth and optimum tread wear of the entire set.

In the absence of vehicle manufacturer rotation recommendations, follow the

rotation patterns in the figures on page 17. Note that certain types of tires

cannot be rotated in the manner shown. Such tires may include directional

and asymmetrical tires. Also, some vehicles may have different sized tires

mounted on the front and rear axles, and these different sized tires have

rotation restrictions. For these special cases, check the recommendations in

the vehicle owner’s manual for proper rotation.

When tires are rotated, the inflation pressures must be adjusted for

the tires’ new positions in accordance with the vehicle manufacturer’s

recommendations; refer to the vehicle tire placard, certification label or

owner’s manual. See “Proper Tire Inflation and Vehicle Loading” on page 11.

If the vehicle has a matching full-size spare tire, it is recommended that it be

included in the tire rotation. Use one of the tire rotation patterns illustrated,

inserting the full-size spare at the right rear position. Always check and adjust

the inflation pressure of the full size spare when incorporating it into the

rotation pattern. Do not include a “Temporary Use” or T-type spare tire in any

of these rotation patterns.

17

Chapter 2, Page 18

FRONT

Vehicles with Dual Rear Wheels (Six-Tire Rotation)

FRONT

FRONT

FRONT

All Vehicles

FRONT

Rear and Four

Wheel Drive Vehicles

FRONT

Front Wheel Drive

Vehicles

FRONT

Rear and Four

Wheel Drive Vehicles

with Full Size Spare Tire

Full

Size

FRONT

All Vehicles

Front Wheel Drive Vehicles

with Full Size Spare Tire

Full

Size

FRONT

FRONT

Rear Tire Irregular Wear

Front Tire Irregular Wear

FIGURE 12: Typical Rotation Patterns When Tires are the Same Size and Type

Typical Rotation Patterns When Tires are the Same Size and Type

18

REGULAR TIRE INSPECTION

Tire Inspection Guidelines

In addition to maintaining proper inflation pressure, regularly inspect the tire

tread and sidewalls for irregular tread wear, cracking, scrapes, bulges, cuts,

snags, foreign objects or other damage resulting from use. Stones, glass, and

other foreign objects embedded in the tread should be removed to prevent

further damage. Even minor damage can lead to further injury and eventual

tire failure. Tires with excessive cracking on the tread or sidewall(s) should

be removed from service. This is typically caused by under inflation, over

loading, improper storage, and/or improper long-term parking.

Consumers should check their tire tread and sidewall areas during monthly

inflation pressure checks, looking for uneven or irregular tread wear or

other conditions as noted above. It is recommended that tires, including the

spare, be periodically inspected by a tire service professional during routine

maintenance intervals such as oil changes and tire rotations.

Replace tires when worn to 2/32” tread depth remaining anywhere on the

tread face. Built-in tread wear indicators or “wear bars”, which look like

narrow strips of smooth rubber across the tread, will appear on the tire when

the tread is worn to 2/32”. When a wear bar is flush with the tread surface,

the tire is worn out and it is time to replace it. If not replaced, loss of traction

in adverse weather conditions is more likely to occur.

Driving on damaged tires is dangerous. A damaged tire can suddenly fail

leading to situations that may result in serious personal injury or death.

Tires should be regularly inspected by a qualified tire service professional.

19

Tread Wear Indicators/Wear Bar

Based on the tread wear indicators on the tire above, the tire is worn out

In addition to wear out, if any of the following conditions below are found

when inspecting a tire, rim/wheel or valve, the item should be removed from

service. (Note: this list is not all-inclusive.)

• Localized spot wear

• Exposed wire cord or fabric material

• Unrepairable punctures

• Previous improper repairs

• Bulges, blisters

• Deep cuts/cracks

• Run flat damage

• Bent, cracked, corroded or damaged rim/wheel

• Damaged valve and/or valve core

Consult a tire service professional with any questions or concerns regarding

tire, rim/wheel or valve conditions.

The “Penny Test” is an easy way to determine if your

tires are worn out. The test requires a penny. Place

the penny upside down into a tread groove of a tire. If

part of Lincoln’s head is covered by the tread, the tires

have the proper amount of tread. If you can see all of

Lincoln’s head, it is time to replace the tire.

20

Tire Service Life

It is important to have tires in good operating condition, thus tires may need

to be replaced because of service conditions long before the tread is worn

out. To determine if tires, including the spare, should remain in service,

it is recommended that they be periodically inspected by a tire service

professional during routine maintenance intervals like oil changes and tire

rotations. The service life of tires includes their overall condition and vehicle

usage factors, not just tread wear. All of these factors should be taken into

account when considering tire replacement.

Follow the vehicle and tire manufacturer’s specific recommendations, if any,

regarding tire service life and replacement. In order to determine the age of

the tire, look for the last four digits of the DOT tire identification number (see

“DOT TIN Description” on pages 6 and 7 for identifying the week and year of

manufacture).

Tire Service Life is Not Determined by Chronological Age - Tires are composed

of various materials, including rubber, having performance properties

essential to the proper functioning of the tire. These component properties

evolve over a combination of time, service and storage conditions. For each

individual tire, this change is affected by many elements such as temperature,

storage conditions, and conditions of use (e.g., load, speed, inflation pressure,

impacts and road hazard injury) to which a tire is subjected throughout its life.

Since service and storage conditions vary widely, accurately predicting the

service life of any specific tire based on calendar age is not possible. USTMA

is not aware of scientific or technical data that establishes or identifies a

specific minimum or maximum service life for passenger and light truck tires.

However, in some cases a tire or vehicle manufacturer may make a specific

tire replacement recommendation regarding its products. If so, the consumer

should consult the manufacturer with any questions with regard to following

the recommendation. Furthermore, any such recommendation should not be

considered a minimum service life for the tire.

Puncture repairs are limited to the tread area as generally depicted above.

21

Puncture repairs are limited to the tread area as generally depicted above.

PROPER TIRE REPAIR

Tires driven even a short distance while under inflated may be damaged

beyond repair. Running a tire under inflated is like running the vehicle’s

engine without enough oil or coolant. It may seem to work fine for a time, but

serious permanent damage has occurred. Adding oil or coolant won’t repair

engine damage, and adding inflation pressure won’t fix tire damage. The tire

will remain seriously damaged and can still fail, even after inflation pressure is

corrected.

Have Your Tire Repaired Properly

Proper tire repairs should be performed by trained tire service professionals

using USTMA or tire manufacturer approved procedures. If a tire continually

loses inflation pressure or has lost all or most of its inflation pressure, it must

be removed from the wheel for a complete internal inspection to check for

damage. For vehicles equipped with dual tire assemblies (duals), if one of the

dual tires becomes significantly under inflated or flat, the other tire will carry

the load for both tires, resulting in an overloaded condition for both tires.

Consequently, both tires should be inspected by a tire service professional for

damage.

Never have a tire repaired with an injury that is greater than ¼ inch in

diameter. Do not repair an injury outside the puncture repair area.

Improperly repaired tires can fail while in service, such as by tread/belt

separation, which can lead to an accident and serious personal injury or death.

Tires must always be properly repaired as described in the USTMA wall chart,

“Puncture Repair Procedures for Passenger and Light Truck Tires.”

22

Not all tires can be repaired. In addition to the USTMA puncture repair

procedures, there may be additional limitations based on individual tire

manufacturer repair policies. These may include the type of service such as

speed rating, load index, run-flat technology and commercial application.

When having a tire repaired, make sure the tire service professional:

• Never performs a tire repair on-the-wheel

• Never uses only a plug (stem)

• Never uses only a patch

If a tire continually loses inflation pressure or has lost all or most of its

inflation pressure, it must be removed from the wheel for a complete

internal inspection to check for damage. Driving on damaged tires is

dangerous. A damaged tire can suddenly fail, including by tread/belt

separation, even at a later date, which can lead to an accident and serious

personal injury or death.

Never perform a tire repair without removing the tire from the wheel

assembly for an internal inspection. Do not perform an outside-in tire

repair or an on-the-wheel repair.

The photos above are an example of a tire that was operated in an

underinflated condition with a puncturing object that caused dangerous,

non-repairable damage to the innerliner and body ply material. This type

of damage would not have been visible from the outside of the tire. Every

tire must be removed from the wheel for an inspection and to assess

repairability.

23

Vehicle Original Equipment Temporary Tire Mobility Kits

A temporary tire mobility kit may be supplied by the vehicle manufacturer

as an alternative to a spare or runflat tire in passenger car and light truck

applications. The temporary tire mobility kit is normally comprised of a

puncture sealant and a small air compressor or container of propellant.

Use of a temporary tire mobility kit:

• Is not considered a repair to the tire

• Only provides a temporary solution to promptly reach a service location

for professional inspection and possible repair of the affected tire. Refer

to tire manufacturer for specific guidelines regarding repairability and

warranty.

End-users of temporary tire mobility kits supplied as original equipment in

a passenger car or a light truck vehicle should always follow all instructions

provided by the vehicle manufacturer, including limits on the amount of

driving at reduced speeds allowed to safely reach a tire service location.

Aftermarket Sealants

The USTMA does not endorse aftermarket sealant products. Aerosol,

liquid, gel or other substances injected into a tire through the valve are not

considered proper repairs. Such products may:

• be flammable and potentially explosive

• damage the tire

• void the tire manufacturer’s warranty

• interfere with or damage tire pressure monitoring system sensors

Consult the tire manufacturer’s service recommendations and warranty

policy.

Flammable propellants and/or liquids in aftermarket sealants or aerosol

inflators may cause a tire to explode under certain circumstances. Never

introduce a flammable substance into a tire. Inform the tire service

TIRE SEALANTS AND BALANCING SUBSTANCES

Solvent-based liquids must not be used due to the possibility of

creating explosive mixtures of vapors in the tire, which may result in

serious injury or death.

24

VEHICLE CONDITION, ALIGNMENT AND MAINTENANCE

There is a close relationship between several mechanical systems on a vehicle

and its tires. Tires, wheels, brakes, shock absorbers, drive train, steering and

suspension systems, among others, must all function together to perform safely

and comfortably and to give optimum tread wear. Improper or inadequate vehicle

maintenance can cause tires to wear rapidly and/or abnormally.

Maintenance Conditions

Improper Tire Inflation - For optimum service, use the inflation pressures

specified by the vehicle manufacturer on the vehicle tire placard, certification

label or owner’s manual. Under inflation may result in rapid and/or abnormal

tread wear, improper vehicle handling and decreased fuel economy. Over inflation

can result in rapid and/or abnormal tread wear, decreased traction and premature

wear of suspension components. See information “Proper Tire Inflation and

Vehicle Loading” on pages 11 through 15.

Vehicle Wheel Misalignment - If the vehicle wheels are not properly aligned,

tires will experience stresses as if they were constantly cornering. This will

cause increased and abnormal tread wear. A qualified mechanic should correct

misalignment of wheels. Front-wheel drive vehicles and those with independent

rear suspension require special attention with alignment of all four wheels.

Lack of Tire Rotation - Tire rotation procedures are established to equalize the

tread wear for each tire to prolong tread life. By regularly changing a tire to

another position on the vehicle, any abnormal wear patterns that were starting to

develop may be corrected. See “Regular Tire Rotation” on page 16).

Tire and Wheel Assembly Out-of-Balance - A tire and wheel assembly that is

out-of-balance can cause abnormal tread wear due to vibration and irregular road

contact which may be worse at specific speeds.

Damaged Wheels – In addition to resulting in possible loss of inflation, damaged

wheels can cause a tire to contact the road unevenly and cause abnormal tread

wear. Wheel damage may not be visually obvious and should be checked by a tire

service professional using proper measuring equipment.

Brakes in Disrepair - If not in proper working order, brakes can grab unevenly and

cause abnormal tread wear.

Worn Struts, Shock Absorbers - A worn strut or shock absorber will not properly

dampen vehicle motion and cause abnormal tread wear.

Worn or Loose Suspension and Steering Systems - Excessive wear and looseness

anywhere in the suspension and steering systems (such as tie-rod ends and ball

joints) can cause tire and wheel assemblies to move in ways in which they were

not designed, resulting in abnormal tread wear.

25

Additional Conditions Affecting Tread Wear

Tread wear is affected by many different vehicle operating conditions.

Abnormal wear typically results from a combination of unsatisfactory conditions

and may make an accurate diagnosis of the cause(s) difficult. It is important

to identify the emergence of abnormal wear in its early stage and correct the

cause before valuable tire tread wear is lost. Most of the causes of abnormal

tread wear can be corrected. The causes can include excessive tire stresses due

to driving habits, road surfaces, terrain and axle position.

Driving Habits - The way a vehicle is driven has a great deal to do with tread

wear and safety. Observe posted speed limits and avoid hard stops, starts and

cornering. In addition, avoid potholes, objects on the road, and curbs (such as

hitting/forcing the tire against the curb when parking). The rate of tread wear

increases during hard cornering at both high and low speeds due to scuffing

caused by lateral forces, particularly on the front tires. Hard acceleration or

braking will also cause increased tread wear due to torque and weight transfer.

Typically the front tires are carrying a greater load and are doing the most

braking.

Road Surfaces/Terrain - Rapid or abnormal tread wear may be caused by

abrasive road surfaces such as those with sharp or coarse highway paving

materials. Areas that have numerous hills or curves can also lead to accelerated

tread wear.

Axle Position - The position of a tire on a vehicle determines what stresses the

tire will experience. The tires on the drive axle are affected by acceleration.

Depending on the vehicle, this can be the rear axle, the front axle or, in the case

of four-wheel drive, both axles. On front-wheel drive vehicles, the front axle

also steers the vehicle and performs most of the braking. Free-rolling, rear tires

may also experience some abnormal tread wear. Rotating tires on the vehicle

may help to minimize abnormal tread wear.

Examples of Abnormal Tread Wear

Diagonal Wear One-Sided Wear Both Shoulder Wear Center Wear

(All of the above tires are worn out)

Heel and Toe Wear Cupping Wear

Spare Tire Maintenance

Spare tire (full-size and temporary spare) inflation pressure should be checked

monthly and before any long trips. Use an accurate gauge. T-type temporary

spare tires require 60 psi (420 kPa). When adjusting inflation pressure in

T-type tires, do so in small amounts since the tire is smaller and the pressure

level changes rapidly. Do not over inflate.

Inspect the spare tire/rim/wheel periodically (i.e. during tire rotation intervals)

for any visible damage to the tire or corrosion on the wheel.

If the vehicle has a matching full-size spare tire, it is recommended that it be

included in the tire rotation. Always check and adjust the inflation pressure of

the full size spare when incorporating it into the rotation pattern.

There may be restrictions on speed, mileage and placement of a temporary

spare tire. Consult the vehicle owner’s manual for use of a temporary spare

tire.

T-type temporary spare tires should only be used with rims/wheels specifically

intended for them. Rims/wheels intended for use with T-type tires should not be

used with any other types of tires. A temporary spare tire and wheel assembly

should never be used on a vehicle with which it is not compatible. Never use

more than one temporary spare tire at a time.

Tire Storage Recommendations

Stored tires should be protected against environmental effects such as

sunlight, high heat, ozone and other potentially damaging conditions.

Weather checking/ozone cracking can occur during direct and extended

exposure to damaging effects of the environment, such as ozone and heat

from sunlight. Ozone cracking can also be caused by exposure to electric

motors, welding equipment, or other ozone generating sources. Tires with

severe weather checking/ozone cracking or any cracking that extends to the

tire casing cords/plies should be removed from service.

Follow the recommendations below when storing tires:

• Store tires where the area is clean, dry and well ventilated, but with a

minimum of circulating air.

• Store tires in an area with temperate ambient conditions (mild

temperatures, shaded or dark).

• Store tires raised off a storage area’s floor surface to minimize exposure

to moisture or damage.

• Avoid contact with petroleum-based products and/or other volatile

solvents or substances.

• Store tires away from electric motors, battery chargers, generators,

welding equipment or other ozone generating sources.

26

27

Indoor storage is recommended, however if tires must be stored outdoors:

• Store tires where they are raised off the ground (or on storage racks) and

not in contact with heat absorbent surfaces.

• Protect tires with an opaque, waterproof covering with some type of

vent openings to avoid creating a “heat box” or “steam bath” effect.

Tires Mounted on a Stored Vehicle - Store the vehicle such that all weight

is removed from the tires. If vehicle weight cannot be removed, unload the

vehicle to minimize the weight. Maintain the recommended tire inflation

pressure, including the spare. The surface where the vehicle is parked/stored

should be firm, reasonably level, well drained and clean. The vehicle should be

moved every three (3) months so the tire flex area is changed.

Returning Tires from Storage Back to Service - Before placing stored tires

back into service, a tire serviceprofessional should conduct a visual and tactile

inspection to be sure each tire is clean, dry, free of foreign objects, and/or

does not show signs of damage. See “Tire Inspection Guidelines” on page 18.

Once mounted on a rim/wheel, the tire (including the spare tire) should be

inflated to the recommended inflation pressure. See “Proper Tire Inflation and

Vehicle Loading” on page 11.

Cleaning Tires

Clean tires with soap and water and a soft bristle brush or a shop cloth.

Treating tires with incompatible dressings or harsh cleaning agents will hasten

oxidation and result in premature cracking. Never use petroleum-based tire

dressings, cleaners or other products. Use of a pressure washer or steam

cleaner may be damaging to the tire. Contact the tire manufacturer for

specific recommendations on cleaning tires.

GOOD DRIVING HABITS

The way you drive has a great deal to do with your tire service life and safety.

Therefore, in addition to proper tire maintenance, cultivate good driving

habits for your own benefit.

• Observe posted speed limits.

• Avoid fast starts, stops and turns.

• Avoid potholes and objects on the road if possible.

• Do not run over curbs or hit the tire against the curb when parking.

The rate of wear increases during hard cornering at both high and low speeds

due to scuffing caused by lateral forces, particularly on the front tires. Hard

acceleration or braking will also cause increased wear due to torque and

weight transfer.

28

Road Hazard and Impact Damage

Punctures, cuts, snags, and other issues can lead to further damage if not

repaired in time. The tire must be demounted and carefully inspected to

determine whether it is repairable. Some road hazard damage may result

in gradual inflation pressure loss. If not corrected as soon as possible,

such damage can ruin tires that could otherwise have been repaired. For

information on proper tire repair, see page 21.

Impact damage to the tire may initially show little or no exterior evidence.

However, internal damage can progress with additional mileage and

eventually cause internal tire separation, detachment or sudden loss of

inflation. Impact damage may cause gradual inflation pressure loss. After

experiencing an impact, have the tire inspected by a tire service professional.

A rim bruise break (pinch shock) occurs when the tire strikes a rigid object

(like a curb or pothole) hard enough to crush the tire’s sidewall between the

rim flange and the rigid object. Vehicles operated off-road or in areas away

from paved roads can encounter many objects that can cause tire damage.

Careful inspection of the tires should be made after use in off-road service.

Sudden Vibration or Ride Disturbance

If the vehicle experiences a sudden vibration or ride disturbance and/or

there is a possibility the tires and/or vehicle have been damaged, gradually

reduce speed. Do not abruptly brake or turn. Drive with caution until you can

safely pull off the road. Stop and inspect the tire. If the tire is under inflated

or damaged, deflate and replace it with the spare tire. If a cause cannot be

detected, the vehicle should be towed to the nearest vehicle or tire dealer for

an inspection.

Tire Spinning

The centrifugal forces created by a rapidly spinning tire can cause an

explosion by literally tearing the tire apart. These forces act on the complete

tire structure, and can be of such magnitude as to break the beads in addition

to rupturing the tire. Some vehicles are able to bring a tire to its centrifugal

force failing point in just 3 to 5 seconds.

Driving on damaged tires is dangerous. A damaged tire can suddenly fail

leading to situations that may result in serious personal injury or death. Tires

should be regularly inspected by a qualified tire service professional.

29

When stuck on ice, snow, mud, or wet grass, the vehicle should be rocked

gently (alternately using forward and reverse gears) with the least amount

of wheel spinning. Repeatedly shift the gear lever from drive to reverse on

automatic transmissions or reverse to second on manual transmissions, while

applying gentle pressure to the accelerator. Vehicles with ABS or traction

control systems may have specific instructions in their owner’s manual.

Wet Weather Driving

Driving too fast on wet roads, through standing water or in the rain, can

cause your tires to hydroplane. This means that your tires travel on a film

of water rather than contacting the road. After a dry spell, rain can further

reduce traction from oil and other substances that have collected on the

roadway. In addition, leaves can hide moisture on a road surface, even

long after the rain has stopped. When roads are wet, slow down and drive

carefully.

Winter/Snow Conditions

Dedicated winter/snow tires are designed to provide enhanced traction and

handling capabilities in adverse winter driving conditions.

Every time the outside temperature drops 10 degrees Fahrenheit, the

inflation pressure inside your tires goes down about 1 to 2 psi. Never reduce

tire pressures in an attempt to increase traction on snow or ice. It does not

work and your tires will be more susceptible to damage from under inflation.

In snowy areas, many cities and counties have “snow emergency” regulations

which are invoked during heavy snowfalls. Check with authorities for the

rules in your area. Under some rules, motorists are subject to fines if they

block traffic and do not have winter tires on their vehicles. Slow down and

drive carefully in adverse winter driving conditions.

Excessive speed in a free-spinning tire can cause the

tire to explode from extreme centrifugal force. The

energy released by such an explosion is sufficient to

cause serious physical injury or death.

Never spin a tire above a speedometer reading of

35 mph (56 km/h). Never stand near a spinning tire.

30

Mountain Snowflake Symbol - This mark is found on winter/snow tires that

meet the USTMA definition for passenger and light truck tires

for use in severe snow conditions. These tires are marked on at

least one sidewall with the letters “M” and “S” (see page 7) plus a

mountain/snowflake pictograph.

Winter/Snow Tire Application - It is always preferable to apply winter/snow

tires to all wheel positions, including duals, to maintain vehicle mobility and

control.

• If winter/snow tires are applied to the front axle of a vehicle, winter/

snow tires must also be installed on the rear axle. Do not apply winter/

snow tires only to the front axle. This applies to all passenger and light

truck vehicles including front-wheel-drive, 4WD, and AWD vehicles.

• If winter/snow tires are installed on the rear axle of any vehicle, it is

recommended (but not required) that they also be installed on the front

axle.

Studded Winter/Snow Tire Application - Studded winter/snow tires have

higher traction qualities under most winter weather conditions.

• If studded winter/snow tires are installed on the front axle of any vehicle,

studded winter/snow tires must also be installed on the rear axle. Do not

apply studded winter/snow tires only to the front axle.

• If studded winter/snow tires are installed on the rear axle of any vehicle,

it is strongly recommended that they should also be installed on the

front axle. Only if studded winter/snow tires are installed on all wheel

positions of a vehicle will optimum handling characteristics be achieved.

• Some states prohibit the use of studded tires and many states have

seasonal limitations on their use. Before installing, check with state and

local regulations.

It is generally acceptable to apply a dedicated winter/snow tire with a lower

speed rating than the OE tire; however, the vehicle speed is to be restricted

to that of the replacement tire.

31

Chains - Make sure chains are the proper size and type for your tires,

otherwise they may damage the tire sidewall and cause tire failure. If you

have dual tires on your vehicle, particular care must be taken to assure

adequate clearance between loaded tires to avoid damage from chains.

Consult a tire service professional or vehicle manufacturer for proper

application.

Installing winter/snow tires (studded or unstudded) only on the front axle may

cause the vehicle to experience adverse handling characteristics. This may

result in an accident, which could cause serious injury or death.

32

TIRE REPLACEMENT GUIDELINES

The Right Tire for the Vehicle

When tires need to be replaced, do not guess what tire is right for the vehicle.

For the answer, refer to the vehicle tire placard and/or certification label,

usually located on the vehicle door edge, door post, glove box or fuel door.

Also, check the vehicle owner’s manual for any additional tire replacement

recommendations. The vehicle tire placard identifies the size of the tires,

including the spare, that were installed on the vehicle as original equipment

(OE). The placard also specifies the recommended cold inflation pressures

for the tires on the front/rear axles and for the spare. If the vehicle does not

have a vehicle tire placard or certification label, consult the vehicle owner’s

manual, vehicle manufacturer, or tire manufacturer.

EXAMPLE OF A EXAMPLE OF A

VEHICLE TIRE PLACARD VEHICLE CERTIFICATION LABEL

Replacement tires should be the same as the OE size designation, or

approved options, as recommended by the vehicle or tire manufacturer.

Never choose a replacement tire of a smaller tire size or with less load-

carrying capacity than the OE tire size at the specified vehicle placard

pressure. It is recommended that all four tires be of the same size, speed

rating, and construction (radial, non-radial). In some cases, the vehicle

manufacturer may require different sized tires for either the front or rear

axles.

Selecting a tire or rim/wheel other than that recommended by the vehicle

manufacturer is a complex process that requires extensive knowledge and

training. Consult a tire service professional.

NOTE

Before replacing tires, ALWAYS refer to and follow the vehicle manufacturer’s tire

replacement recommendations and restrictions.

33

Self-Supporting Runflat Tires

Runflat tires have specific servicing requirements, such as product-specific

puncture repair or demounting/mounting procedures, which vary by vehicle

and tire manufacturer. Consult with the tire manufacturers for details. A

functioning tire pressure monitoring system (TPMS) must be used with runflat

tires. Never mix runflat tires with conventional tires unless in an emergency

situation on a limited, temporary basis.

Tire Mixing

• It is recommended that all four tires be of the same size, load index

and speed rating. In some cases the vehicle manufacturer may require

different sized tires for either the front or rear axles. Never mix P-Metric

or Metric passenger tires with light truck tires, including C-Type

European Commercial tires, on the same vehicle.

• Speed rated tire - If the vehicle tire placard and/or owner’s manual

specifies speed rated tires, the replacement tires must have the same

or higher speed rating to maintain vehicle speed capability. Tire speed

ratings do not imply that vehicles can be safely driven at the maximum

speed for which the tire is rated, particularly under adverse road and

weather conditions, or if the vehicle has unusual characteristics. Never

operate a vehicle in an unsafe or unlawful manner.

If replacement tires have lower speed capability than specified by the

vehicle manufacturer, the vehicle’s speed must be restricted to that of the

replacement tire. Also, vehicle handling could be affected. Consult the vehicle

manufacturer or the tire manufacturer for recommendations.

• Four-wheel drive (4WD) and all-wheel drive (AWD) vehicles - If no

instructions for tire mixing appear in the vehicle owner’s manual, follow

these guidelines:

- Do not mix tire sizes. All four tires must be marked with the same

tire size, unless otherwise specified by the vehicle manufacturer. This

also applies to dedicated winter/snow tires.

- Do not mix tread pattern types such as all-terrain and all-season.

For use of dedicated winter/snow tires, see page 29.

34

NOTE

In some cases, the vehicle manufacturer may specifically advise against replacing less

than all four tires. Always check and follow the recommendations in the vehicle owner’s

manual. For 4WD and AWD vehicles, even small differences in outside diameter may

cause drive-train damage or mechanical malfunction.

Driving on damaged tires is dangerous. A damaged tire can suddenly fail leading

to situations that may result in serious personal injury or death. Tires should be

regularly inspected by a qualified tire service professional.

Replacing Less Than Four Tires

When replacing tires on a vehicle, it is recommended and preferred that

all four tires be replaced at the same time for continued optimal vehicle

performance. However, for those cases where this is not feasible, below are

some general guidelines to consider when replacing less than four tires for a

light vehicle, whether it is one or two tires.

Replacing Two (2) Tires - When a pair of replacement tires is selected in

the same size and construction as those on the vehicle, the two newer

tires should be installed on the rear axle. Generally, new tires with deeper

tread will provide better grip and evacuate water more effectively, which

is important as a driver approaches hydroplaning situations. Placing greater

traction on the rear axle on wet surfaces is necessary to prevent a possible

oversteer condition and loss of vehicle stability.

Replacing One (1) Tire - Replacing a single tire on a vehicle can have an

adverse effect on suspension systems, gear ratios, transmission, and tire tread

wear. If single tire replacement is unavoidable, it is recommended that the

single new tire be paired with the tire that has the deepest tread and both

be placed on the rear axle. Placing greater traction on the rear axle on wet

surfaces is necessary to prevent a possible over steer condition and loss of

vehicle stability.

Used Tires

This information pertains to used passenger and light truck tires installed as

replacement tires or as equipped on a used vehicle.

35

Once tires are applied to a vehicle and put into service (this includes spare

tires), they are considered “used.” There is a potential risk associated with the

installation of used tires that have an uncertain or unknown history of use,

maintenance or storage conditions. Such tires may have damage that could

eventually lead to tire failure.

Not all tire damage that can lead to tire failure is outwardly visible. For

instance, improper repairs or damage to a tire’s inner liner can only be

observed by inspecting the inside of the tire, demounted from the wheel. A

qualified tire service professional should inspect the internal and external

condition of a used tire prior to application. In the case of a used vehicle

purchased by a consumer, the only way to determine the condition of its tires

is to have them demounted by a tire service professional for the same type of

inspection.

U.S. Tire Manufacturers Association • 1400 K Street, NW, Suite 900 • Washington, DC 20005

www.USTires.org

© 2018 U.S. Tire Manufacturers Association