©2018 TurboChef Technologies, Inc. DOC-1559 / Rev C / Sept 2018

TurboChef Technologies, Inc.

Double Batch (HHD) Ventless Submittal Information

Double Batch Spec Sheet

UL Ventless Label

Notice of Authorization to Apply the UL Mark (Sanitation)

Notice of Authorization to Apply the UL Mark (Safety)

UL KNLZ Explained

Emissions Test Results

Emissions by Product

Energy Usage Estimate

Double Batch Surface Temperatures

TurboChef Installation Recommendations

1.1

2.1

5.1

6.1

4.1

7.1

8.1

9.1

10.1

11.1

UL Listing 3.1

Project _______________________________________________________

Item No. ______________________________________________________

Quantity _____________________________________________________________________

THE

Double Batch

TM

EXTERIOR CONSTRUCTION

n

Stainless steel front, top and sides

n

Rubber seal for surface mounting

INTERIOR CONSTRUCTION

n

304 stainless steel

n

Two fully insulated cook chambers

n

Top and bottom jetplates

STANDARD FEATURES

n

Simple and intuitive touch controls

n

Multi-language user interface

n

Integral recirculating catalytic converter for UL (KNLZ) listed

ventless operation

n

Variable-speed High h recirculating air impingement system

n

Oscillating rack for high heat transfer without spotting

n

Half-sheet pan/16-inch pizza capacity

n

Stackable design (requires stacking kit)

n

Smart menu system capable of storing up to 128 recipes: 64 recipes

per cavity

n

Built-in self diagnostics for monitoring oven components

and performance

n

USB compatible

n

Wi-Fi compatible

n

Free one-year subscription to TurboChef Connect menu management

web portal

n

Smart Voltage Sensor Technology* (N.A. only)

n

Includes plug and cord (6 ft. nominal)

n

Warranty − 1 year parts and labor

STANDARD ACCESSORIES

n

1 Aluminum Paddle (NGC-1478)

n

1 Bottle Oven Cleaner (103180)

n

1 Bottle Oven Guard (103181)

n

2 Trigger Sprayers (103182)

n

4 Oven Legs (HHB-3205) – Optional

1. Blower Motor

2. Impinged Air

3. Oscillating Rack

4. Catalytic Converter

5. Impingement Heater

6. Halogen Lights

PERFORMANCE

The TurboChef® Double Batch

TM

oven has

two independent cavities that circulate

impinged air at speeds of up to 50 mph

to create high heat transfer rates and

reduced cook time. The oven utilizes

variable speed blowers, oscillating racks,

and catalytic converter, resulting in

minimal energy input, high food quality,

and ventless operation.

VENTILATION

n

UL (KNLZ) listed for ventless operation.

†

n

EPA 202 test (8 hr):

- Product: Pepperoni Pizzas

- Results: 1.04 mg/m

3

- Ventless Requirement: <5.00 mg/m

3

n

Internal catalytic filtration to limit

smoke, grease, and odor emissions.

1

1

3

2

2

2

2

3

4

4

5

5

6

6

Double Batch

TM

DOC-1540 / Rev C / September 2016

This product conforms to the ventilation recommendations set forth by NFPA96 using

EPA202 test method.

* Smart Voltage Sensor Technology does not compensate for lack of or over voltage situations. It is the

responsibilityoftheownertosupplyvoltagetotheunitaccordingtothespecicationsonthebackofthissheet.

†

Ventlesscerticationisforallfooditemsexceptforfoodsclassiedas“fattyrawproteins.”Suchfoodsinclude

bone-in, skin-on chicken, raw hamburger meat, raw bacon, raw sausage, steaks, etc. If cooking these types of

foods, consult local HVAC codes and authorities to ensure compliance with ventilation requirements.

Ultimate ventless allowance is dependent upon AHJ approval, as some jurisdictions may not recognize the

UL certification or application. If you have questions regarding ventless certifications or local codes please

email [email protected]

TurboChefreservestherighttomakesubstitutionsofcomponentsorchangespecicationswithoutpriornotice.

Page 1.1

DIMENSIONS

Single Units

Heigh

t 23.2” 589 mm

Width 27.7” 704 mm

Depth (Door Open/

Closed)

35.6” / 31.7” 903 mm / 806 mm

Weight 262 lb. 119 kg

Stacked Units

Heigh

t 46.4” 1,179 mm

Width 27.7” 704 mm

Depth (Door

Open/

Closed)

31.7”

/ 35.6” 806 mm / 903 mm

Weight 524 lb. 238 kg

Cook Chamber

Height 3.3” 84 mm

Width 18.1” 318 mm

Depth 17.07” 434 mm

Volume 0.59 cu.ft. 16.7 liters

Wall Clearance (Oven not intended for built-in installation)

Top 2” 51 mm

Sides 2” 51 mm

ELECTRICAL SPECIFICATIONSSINGLE PHASE

Double Batch

US M

odel (

HHD

-9500-1) -

Unit

ed

Stat

es

Voltage 208/240 V

AC

Fr

equency 60

Hz

Cur

rent (Max Circuit

Requiremen

t) 50 amp (50 amp)

Max Input 10,720/12,480 watts

ELEC

T

RICAL SPECIFICATIONS

3

PHASE

D

ouble Batch

US M

odel (

HHD

-9500-14-DL) -

Unit

ed

Stat

es

Voltage 208/240 V

AC

Fr

equency 60

Hz

Cur

rent (Max Circuit

Requiremen

t) 30 amp (30 amp)

Max Input 6,683/7,552 watts

SHIPPING INFORMATION

U.S.: All ov

ens shipped within the

U.S. ar

e packaged in a double-wall

corrugated box banded to a wooden skid.

International:

All In

ternational ovens shipped via

Air or Less than C

ontainer

Loads are packaged in wooden crates.

Box size: 37” x 36” x 35” (940 mm x 914 mm x 889 mm)

Crate size: 39” x 40” x 36” (991 mm x 1016 mm x 914 mm)

Item class: 110 NMFC #26710 HS code 8419.81

Appx. boxed weight: 322 lb. (146 kg)

Appx. cr

ated weight: 405 lb. (184 kg)

Minimum entry clearance required for box: 35.5”

Minimum entry clearance required for crate: 39.5”

TurboChef recommends installing a type D circuit breaker for all installations.

TurboChef reserves the right to substitute components or change specications without notice.

TurboChef Global Operations

2801 Trade Center Drive / Carrollton, Texas 75007 USA

US: 800.90TURBO (800.908.8726) / International: +1 214.379.6000

Fax: +1 214.379.6073 / turbochef.com

NEMA 6-50P

NEMA 15-30P

Double Batch

TM

©2016 TurboChef Technologies, Inc.

1 in.

(25 mm)

1 in.

(25 mm)

27.7 in.

(704 mm)

27.7 in.

(704 mm)

46.4 in.

(1,179 mm)

23.2 in.

(589 mm)

23.1 in.

(587 mm)

26.1 in.

(664 mm)

28.6 in.

(726 mm)

35.6 in.

(903 mm)

2.5 in.

(62 mm)

7 in.

(177 mm)

2.5 in.

(62 mm)

3.1 in.

(80 mm)

26.1 in.

(664 mm)

28.6 in.

(726 mm)

31.7 in.

(806 mm)

1 in.

(25 mm)

1 in.

(25 mm)

27.7 in.

(704 mm)

27.7 in.

(704 mm)

46.4 in.

(1,179 mm)

23.2 in.

(589 mm)

23.1 in.

(587 mm)

26.1 in.

(664 mm)

28.6 in.

(726 mm)

35.6 in.

(903 mm)

2.5 in.

(62 mm)

7 in.

(177 mm)

2.5 in.

(62 mm)

3.1 in.

(80 mm)

26.1 in.

(664 mm)

28.6 in.

(726 mm)

31.7 in.

(806 mm)

1 in.

(25 mm)

1 in.

(25 mm)

27.7 in.

(704 mm)

27.7 in.

(704 mm)

46.4 in.

(1,179 mm)

23.2 in.

(589 mm)

23.1 in.

(587 mm)

26.1 in.

(664 mm)

28.6 in.

(726 mm)

35.6 in.

(903 mm)

2.5 in.

(62 mm)

7 in.

(177 mm)

2.5 in.

(62 mm)

3.1 in.

(80 mm)

26.1 in.

(664 mm)

28.6 in.

(726 mm)

31.7 in.

(806 mm)

Page 1.2

E319600

COOKING OR HOT FOOD

STORAGE EQUIPMENT

ANSI/NSF#4 81Y5

DOC-1677 / Rev A / August 2018

U.S. PATENTS PENDING

COVERED BY ONE OR MORE OF THE FOLLOWING U.S. PATENTS

5,254,823 5,434,390 5,558,793 5,620,731 5,927,265 5,990,466 6,008,483 6,058,924 6,060,701

6,140,626 6,262,406 6,359,271 6,376,817 7,087,872 7,092,988 7,493,362 8,224,892

COVERED BY MEXICAN PATENT NO. 227157

Commercial Cooking Appliance with Integral Systems for Limiting the

Emissions of Grease Laden Air

This product conforms to the ventilation recommendations set forth by NFPA96

using EPA202 test method.

Aparato de Cocina Comercial con Sistemas Integrales para Limitar las Emisiones

de Aire cargado de Grasa

Este producto se conforma a la serie de recomendaciones de ventilación

expuestas por NFPA96 Utilizando el Método de Prueba EPA202.

Appareil de cuisson commercial avec des systèmesqui limitent l'évacuation des

vapeurs grasses

Ce produit est conforme aux recommandations de ventilation spéciée par la

norme. NFPA96, testé à l'aide de la méthode EPA202.

9/17/2018 COMMERCIAL COOKING APPLIANCES | UL Product iQ

https://iq.ulprospector.com/en/profile?e=62498 1/1

KNGT.E319600 - COMMERCIAL COOKING APPLIANCES

Commercial Cooking Appliances

See General Information for Commercial Cooking Appliances

TURBOCHEF TECHNOLOGIES INC E319600

2801 Trade Center Drive

Carrollton, TX 75007 USA

Ovens, Model(s) "Fire"., FIRE-AU, HHD, HHS

Some models may also have Food Service Equipment, Sanitation Certification.

Last Updated on 2018-03-29

The appearance of a company's name or product in this database does not in itself assure that products so identified have been

manufactured under UL's Follow-Up Service. Only those products bearing the UL Mark should be considered to be Certified and covered

under UL's Follow-Up Service. Always look for the Mark on the product.

UL permits the reproduction of the material contained in the Online Certification Directory subject to the following conditions: 1. The Guide

Information, Assemblies, Constructions, Designs, Systems, and/or Certifications (files) must be presented in their entirety and in a non-

misleading manner, without any manipulation of the data (or drawings). 2. The statement "Reprinted from the Online Certifications

Directory with permission from UL" must appear adjacent to the extracted material. In addition, the reprinted material must include a

copyright notice in the following format: "© 2018 UL LLC".

UL and the UL logo are trademarks of UL LLC ©2018 All Rights Reserved.

About Privacy Policy Terms & Conditions Access Your Data

Page 4.1

Page 4.2

NOTICE OF COMPLETION

AND

AUTHORIZATION TO APPLY THE UL MARK

This is an electronically generated letter. Signatures are not required for this document to be valid. Page 1 of 1

08/25/2016

TurboChef Technologies Inc

David Castillo

2801 Trade Center Drive

Carrollton Tx 75007, United States

Our Reference:

File E151488, Vol. 1

Project Number

4787358539

Your Reference:

David Castillo - 26Feb2016

Project Scope:

New Oven Model HHD: Sanitation Investigation

Dear David Castillo:

Congratulations! UL's investigation of your product(s) has been completed under the above Reference Number and

the product was determined to comply with the applicable requirements. This letter temporarily supplements the UL

Follow-Up Services Procedure and serves as authorization to apply the UL Mark at authorized factories under UL's

Follow-Up Service Program. To provide your manufacturer(s) with the intended authorization to use the UL Mark,

you must send a copy of this notice to each manufacturing location currently authorized under File E151488, Vol. 1

and including any special instructions as indicated in the addendum to this letter.

Records in the Follow-Up Services Procedure covering the product are now being prepared and will be sent in the

near future. Until then, this letter authorizes application of the UL Mark for 90 days from the date indicated above.

Additional requirements related to your responsibilities as the Applicant can be found in the document “Applicant

responsibilities related to Early Authorizations” that can be found at the following web-site:

http://www.ul.com/EAResponsibilities

Any information and documentation provided to you involving UL Mark services are provided on behalf of UL LLC

(UL) or any authorized licensee of UL.

We are excited you are now able to apply the UL Mark to your products and appreciate your business. Feel free to

contact me or any of our Customer Service representatives if you have any questions.

Very truly yours,

Reviewed by:

R. Rynkiewicz

Bruce A. Mahrenholz

847-664-2631

847-664-3009

Senior Staff Engineer

CPO Director

NBKB622-2E6192

NOTICE OF COMPLETION

AND

AUTHORIZATION TO APPLY THE UL MARK

This is an electronically generated letter. Signatures are not required for this document to be valid. P

age 1 of 1

08/09/2016

TurboChef Technologies Inc

David Castillo

2801 Trade Center Drive

Carrollton, TX 75007, United States

Our Reference: File E319600, Vol. 1 Project Number 4787358539

Your Reference: David Castillo – 26 Feb 2016

Project Scope: E319600 V2 – Commercial Double Oven Model HHD: Safety Certification Project Completion

Dear David Castillo:

Congratulations! UL's investigation of your product(s) has been completed under the above Reference Number and

the product was determined to comply with the applicable requirements. This letter temporarily supplements the UL

Follow-Up Services Procedure and serves as authorization to apply the UL Mark at authorized factories under UL's

Follow-Up Service Program. To provide your manufacturer(s) with the intended authorization to use the UL Mark,

you must send a copy of this notice to each manufacturing location currently authorized under File E151487, Vol. 1.

Records in the Follow-Up Services Procedure covering the product are now being prepared and will be sent in the

near future. Until then, this letter authorizes application of the UL Mark for 90 days from the date indicated above.

Additional requirements related to your responsibilities as the Applicant can be found in the document “Applicant

responsibilities related to Early Authorizations” that can be found at the following web-site:

http://www.ul.com/EAResponsibilities

Any information and documentation provided to you involving UL Mark services are provided on behalf of UL LLC

(UL) or any authorized licensee of UL.

We are excited you are now able to apply the UL Mark to your products and appreciate your business. Feel free to

contact me or any of our Customer Service representatives if you have any questions.

Very truly yours, R

eviewed by:

R. Rynkiewicz

Bruce A. Mahrenholz

847-664-2631

847-664-3009

Senior Staff Engineer CPO Director

Richard.P.Rynkiewicz@ul.com

Bruce.A.Mahren[email protected]

NBKB621-6DDE84

2016-08-02

Mr. David Castillo

Turbochef Technologies Inc

4240 International Pky

Carrollton, TX 75007

Suite 105

E-mail: [email protected]

Our Reference: File E151487, Project 4787369694

Your Reference: D Castillo 22APR2014

Subject: E151487 - COMPLEMENTARY LISTING FOR MODEL HHD OVEN

Mr. Castillo:

Per your request, project 4787369694 was opened for the evaluation of grease-laden vapors produced by the Model

HHD oven. The scope of the project was to test this model in accordance with EPA Method 202 test guidelines to

demonstrate compliance with UL710B, the Standard for Recirculating Systems, Sec. 17 and NFPA96, the Standard for

Ventilation Control and Fire Protection of Commercial Cooking Operations, paragraph 4.1.1.2 for Complimentary Listing

under UL's KNLZ category. The test was conducted at our facility in Northbrook, IL on April 17

th

, 2016. This letter will

report the results of the EPA202 test.

For the record, the test was conducted on the Model HHD oven, cooking frozen 12 in. pepperoni pizzas (Tombstone,

with 19 pepperonis per pizza) as specified in Appendix A. Please see the attached page (Appendix A) for the test

method and results of the tests. The results are considered to comply with UL710B, Section 17 and NFPA96,

paragraph 4.1.1.2 since the measured values were less than the 5 mg/m

3

limit.

Due to the Safety evaluation

(4787358539) not being completed, this letter will serve to report that all tests on the

subject product have been completed with acceptable results. After the successful completion of the safety project

(4787358539), a Service Request will be opened to add the Complementary Listing to the Model HHD oven. All

information generated will be retained for future use. This concludes all work associated with project 4787369694 and

we are therefore closing this project. Our Accounting Department has been instructed to bill you for all charges

incurred.

Should you have any questions or comments concerning the above, please feel free to contact the undersigned.

Any information and documentation involving UL Mark services are provided on behalf of UL LLC or any authorized

licensee of UL.

Sincerely, Reviewed by:

Bill Morler Fred Zaplatosch

Sr. Project Engineer Sr. Staff Engineer

Tel: 847-664-1852 E-mail: [email protected]

E-mail: [email protected]

A P P E N D I X: A

TEST FOR EVOLUTION OF SMOKE OR GREASE-LADEN AIR ( 500 F):

The model HHD cooking appliance was placed under a hood operating at 500 CFM, and was

tested using a method derived from EPA Method 202. The Underwriters Laboratories also provided

Pepperoni Pizza for the test.

A 12 in. by 6 in. rectangular, 108 in. tall sheet metal stack was constructed on top of the hood.

A sampling port was located approximately 80 in. downstream from the hood exhaust, at which point it

was determined there was laminar flow. The sampler was assembled and an out of stack filter was used.

A pre-leak check was conducted and determined to be < 0.02 ft/min. Sampling was determined to be

done at 8 traverse points.

The oven was operated normally by cooking the following foods:

Convection Oven:

12 in. pepperoni pizza (Tombstone, with 19 pepperonis per pizza), each cooked for _4_ minutes

with 30 seconds (top) and 4 minutes (bottom) between loads for 8 hours (total of 214 pizzas).

Oven was set to maintain 500 °F

Temp Event # %

Time.m:s

% Top

Fan

% Bottom

Fan

% Microwave

Energy

500 °F 1 4:30 50 -- N/A

500 °F 2 4:00 -- 50 N/A

The cooking cycle was repeated for 8 hours of continuous cooking.

During the cooking operation, it was noted whether or not visible effluents evolved from the air

exhaust of the hood. Gauge, meter and temperature readings were taken and recorded every 10 min.

After cooking, the condition of the duct was noted and a post-leak check was conducted and determined

to be < 0.02 ft³/min.

After being allowed to cool, the sampling equipment was disassembled. The glass-filter is to be

removed using a pair of forceps and placed in a clean petri dish. The dish is to be sealed and labeled

"SAMPLE 1".

A sample of the acetone of the same volume that will be used to rinse-out the nozzle and probe is

to be placed into a clean sample bottle, sealed, and labeled "SAMPLE 2". The level of the liquid in the

sample bottle is to be recorded.

The inside of the nozzle and probe is to be rinsed with acetone taking care to collect all the rinse

material in a clean sample bottle. The sample bottle is to be sealed, labeled "SAMPLE 3", and the level

of the liquid in the bottle is to be recorded.

The liquid in the first three impingers is to be measured and the total volume is to be recorded

which will be compared to the original volume. The liquid is to be quantitatively transferred to a clean

sample bottle. Each impinger and the connecting glassware including the probe extension are to be

rinsed twice with water. The rinse water is to be collected and added to the same sample bottle. The

sample bottle is to be sealed, labeled "SAMPLE 4" and the level of the liquid in the bottle is to be

recorded.

This rinse process is to be repeated with two rinses of methylene chloride (MeCl

2

). The rinses

are to be recovered in a clean sample bottle. The sample bottle is to be sealed, labeled "SAMPLE 5" and

the level of the liquid in the bottle is to be recorded.

A volume of water approximately equivalent to the volume of water used to rinse and a volume of

MeCl

2

approximately equivalent to the volume of MeCl

2

used to rinse is to be placed in two clean sample

bottles. The sample bottles are to be sealed, labeled "SAMPLE 6" and "SAMPLE 7" respectively, and the

level of the liquid in the bottles is to be recorded.

The weight of the fourth impinger containing the silica gel is to be recorded and then the silica gel

can be discarded.

The analysis phase was done in accordance with EPA Method 202, using the out of stack filter.

RESULTS

The results [are] [are not] considered acceptable because there [was] [was no] visible smoke

emitted from the exhaust of the hood during the normal cooking operation. There [was] [was no]

noticeable amounts of smoke accumulated in the test room after 8 hours of continuous cooking.

The total amount of grease-laden effluents collected by the sampling equipment was found to be

1.04 mg/m³, which is [less] [more] than 5 mg/m³.

The total grease emissions (per clause 78.2 of 710B) in pounds per hour per linear food of hood

was 0.000593 lb/hr/ft.

Note: Total avg. temp/humidity for 8hrs:

Average Stack temperature: 27.2°C

Average Stack humidity: 26.3%

0

1

2

3

4

5

6

0

100

200

300

400

500

600

Bullet/

Encore

C3

Double

Batch

Eco Fire HhB

HhC

1618

HhC

2020

HhC

2620

i3 i5

Single

Batch

Sota

Tornad

o

Product Cooked Per 8-hour Period

272 180 214 162 222 190 311 480 576 160 240 131 280 160

Emissions

0.13 1.35 1.04 0.89 0.48 0.4 1.12 1.91 2.4 0.32 2.8 0.52 0.64 0.21

Emissions

Product Cooked Per 8-hour Period

UL® (KNLZ)

Emissions by Product

Ventless Requirement: <5.00 mg/m³

TurboChefEnergyCalculator

UserInputs

TotalOperationTimeperDay(hours) 12 hours

CookCycleTime(seconds) 180 seconds

NumberofCooksperDay 100 total

EnergyCost/kWhr($) 0.11 $/kWhr

Constants

DoubleBatch

PowerWarm‐up(watts) 1,740

PowerCooking(watts) 7,360

PowerIdle(watts) 1,700

TimeWarm‐up(seconds) 600

Energy=(Powerxtime),wherepowerisinwattsandtimeisinse

conds

Et

otal=Eidle+Ecooking+Ewarmup

AvePower=Etotal/totaltimeperday

CalculatedTimes

DoubleBatch

Time(cooking,sec) 18,000

Time(idle,sec) 24,600

TimeCheck 12

Eidle(kJ) 41,820

Ewarm‐up(kJ) 1,044

Ecooking(kJ) 132,480

Etotal(kJ) 175,344

Etotal(kWHr) 48.71

AvgPower/Day(kW) 4.06

TonsofCooling 1.15

Cost/Day($) $5.36

Cost/Month($) $160.80

Cost/Year($) $1,956.40

DOC-1556 / Rev A / July 2016

Page 1 of 2

© 2016 TurboChef Technologies, Inc.

TM

Double Batch Oven Surface Temperatures

TURBOCHEF TECHNOLOGIES, INC.

e illustrations in this document represent the surface testing data reported for the TurboChef oven model

HhD during idle and during cooking after two and a half hours of idle at 5000F (2600C), simulating the

highest temperature condition.

Fahrenheit Measurements (Idle/Cooking)

118

136 140

134

118 100 84

177

237

246 240

239

152 89

167

199

201 190

190

158 87

156 179

181 168

167

161 86

161

239

242 239 230 150 86

120

123

125 123

120

107 89

84

100

105

93

89

86

330

338

80

80 82

82

86 113 118

80

77

84 82

93

123 109

80

77

80 84

104

127 114

86 75

86 86

95

143 127

78

75

82 82 89 111 109

77

78

82 86

91

100 102

149

120

127

147

116

105

98

111 116

122

118 105 109

95

104

109 116

118

107 143

96

100

104 109

116

118 140

104

98

100 104

111

118 138

109

100

100 102 107 118 136

107

104

102 102

107

116 129

109

109

114 114

109

111 122

111

125

129 131

116

111 111

77

82 80

80

82 80 78

80

80

82 82

82

80 78

80

80

80 82

82

80 78

80

80

80 80

80

78 78

80

80

80 78 78 78 78

78

80

80 78

78

78 77

78

80

80 80

80

78 77

78

80

80 80

80

78 77

80

78

78

78

75

77

77

77

Left Side

Right Side

Front

Top

Back

78

82 93

96

102 107 109

80

84

102 98

100

100 109

80

84

95 98

98

98 114

80

84

95 98

100

102 118

80

84

140 118 111 114 150

82

84

111 120

113

118 134

80

84

91 91

89

95 113

109

104

104

109

129

138

113

DOC-1556 / Rev A / July 2016

Page 2 of 2

© 2016 TurboChef Technologies, Inc.

Celsius Measurements (Idle/Cooking)

48

58 60

57

48 30 29

81

114

119 116

115

67 32

75

93

94 88

88

70 31

69 82

83 76

75

72 30

72

115

117 115 110 66 30

49

51

52 51

49

42 28

29

38

41

34

32

30

27

27 28

28

30 45 48

27

25

29 28

34

51 43

27

35

27 29

40

53 46

30 24

30 30

35

62 53

26

24

28 28 32 44 43

25

26

28 30

33

38 39

65

49

53

64

47

41

166

170

37

44 47

50

48 41 43

35

40

43 47

48

42 62

36

38

40 43

47

48 60

40

37

38 40

44

48 59

43

38

38 39 42 48 58

42

40

39 39

42

47 54

43

43

46 46

43

44 50

44

52

54 55

47

44 44

25

28 27

27

28 27 26

27

27

28 28

28

27 26

27

27

27 28

28

27 26

27

27

27 27

27

26 26

27

27

27 26 26 26 26

26

27

27 26

26

26 25

26

27

27 27

27

26 25

26

27

27 27

27

26 25

27

26

26

26

24

25

25

25

Left Side

Right Side

Front

Top

Back

26

28 34

36

39 42 43

27

29

39 37

38

38 43

27

39

35 37

37

37 46

27

29

35 37

38

39 48

27

29

60 48 44 46 66

28

29

44 49

45

48 57

27

29

33 33

32

35 45

43

40

39

43

54

59

45

©2018 TurboChef Technologies, Inc.

DOC-1448 / Revision E / August 2018

TM

Installation Recommendations

TURBOCHEF TECHNOLOGIES, INC.

Page 1 of 2

Oven Voltage Current Phase

Bullet 208/240 VAC 30 amp 1 Ph

C3 208/240 VAC

50 amp 1 Ph

Double Batch 208/240 VAC

208/240 VAC

50 amp

30 amp

1 Ph

3 Ph

Eco

Encore/Encore 2 208/240 VAC 30 amp 1 Ph

Fire 208/240 VAC 30 amp 1 Ph

HhB 2 208/240 VAC 30 amp 1 Ph

HhC 1618 208/240 VAC

208/240 VAC

30 amp

50 amp

3 Ph

1 Ph

HhC 2020 208/240 VAC 50 amp 3 Ph

HhC 2620 208/240 VAC 50 amp 3 Ph

i1 (Panini, Soˇta,

Waterless Steamer)

208/240 VAC 30 amp 1 Ph

i1 Soˇ ta Single Mag 208/240 VAC 20 amp 1 Ph

i3 208/240 VAC

208/240 VAC

40 amp

30 amp

1 Ph

3 Ph

i5 208/240 VAC

208/240 VAC

50 amp

30 amp

1 Ph

3 Ph

Single Batch 208/240 VAC 30 amp 1 Ph

Tornado 208/240 VAC 30 amp 1 Ph

Menu Requirements

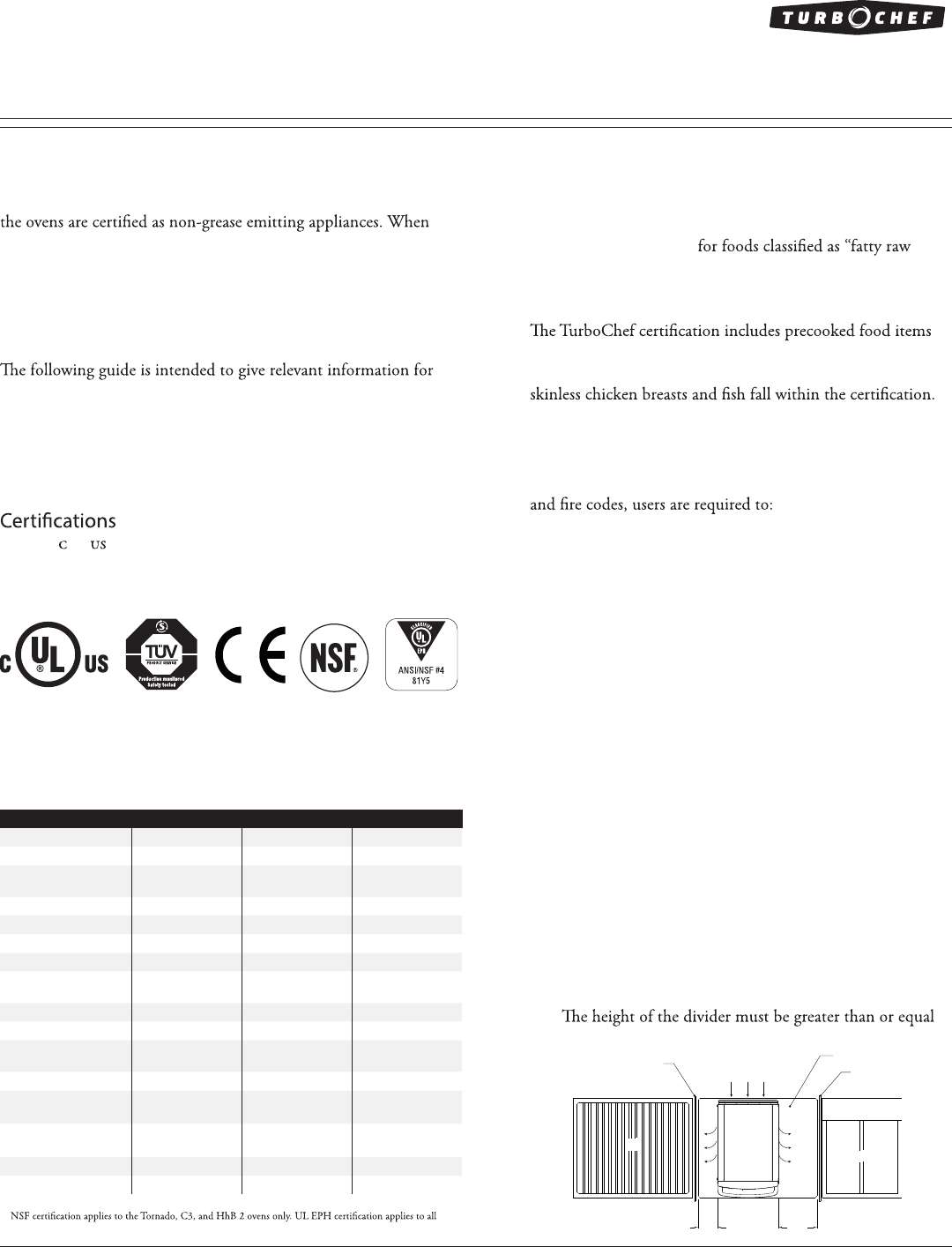

TurboChef ovens have been approved by Underwriter’s

Laboratory for ventless operation (UL KNLZ listing) for

all food items EXCEPT

proteins.” Such foods include bone-in, skin-on chicken, raw

hamburger meat, raw bacon, raw sausage, steaks, etc.

such as pizza toppings, sandwich meats, frozen appetizers,

and cheeses. Additionally, raw, lean meats such as boneless,

Cleaning Requirements

To ensure continued compliance with all health, building,

Use only TurboChef-approved cleaning chemicals.

Follow monthly and quarterly cleaning instructions

provided in the manual. Post cleaning instructions near

the oven.

Ventless installation requires that the areas around

the oven (walls, ceilings, kitchen equipment, etc.)

be cleaned as needed but no less than once every

other month.

Installation Near Open Heat Source

When placing a TurboChef oven near an open heat source

(see illustration below), strictly adhere to the following:

• If the oven is being placed near a grill or stove, a divider

must exist between the oven and the open heat source,

with a minimum of 6” (152 mm) between the oven and

the divider.

• If the oven is being placed near a fryer, a divider must

exist between the oven and fryer, with a minimum of 12”

(305 mm) between the oven and the divider.

•

to the height of the oven.

Grill

Partition

Height Equal to

Oven Height

Oven

6”

(152 mm)

Minimum

12”

(305 mm)

Minimum

Deep Fryer

Counter Top / Table

Partition

INLET AIR

E

X

H

A

U

S

T

E

X

H

A

U

S

T

Height Equal to

Oven Height

TurboChef ventless ovens have internal systems for destroying

grease laden vapor prior to the grease escaping the oven; therefore,

following our recommendations, TurboChef ovens can be installed

without the aid of a Type I or Type II hood per International

Mechanical Code (2006, 2009, and 2012), NFPA 96, NFPA 101

(Life Safety Code), EPA 202, and Underwriter’s Laboratory

(UL KNLZ).

the ventless installation, operation, and maintenance of TurboChef

ovens. It is important that these guidelines are followed and that

the oven and surrounding areas be maintained regularly for

optimal performance.

Safety – UL , TUV (CE)

Sanitation – NSF

*

, UL EPH

*

Ventless – UL (KNLZ)

Electrical Requirements

TurboChef ovens must be installed on a circuit equal to the ratings

listed below, per NEC sec 210.23, permissable loads.

*

ovens except the C3.

Page 11.1

Ventilation

TurboChef ovens must be installed in a well-ventilated space.

foot of kitchen space and an additional 100 sq. ft. (9.3 m

2

)

of virtual space per ventless cooking appliance (TurboChef or

any other).

If the air inlet is for general exhaust, pursuant to requirements

for 507.2.2, paragraph 2, locate the air inlet above the center

point of each oven.

only latent heat present is due to evaporation during the

cooking process. When installing a TurboChef oven, the

space must have the following tons of AC per oven installed.

Oven Tons of AC

Bullet 0.5

C3 0.63

Double Batch 1.15

Eco 0.89

Encore/Enc

ore 2 0.45

Fire 0.55

HhB 2 0.84

HhC 1618 1.00

HhC 2020 1.47

HhC 2620 1.82

i1 (Panini, Soˇta/ Soˇ ta Single Mag,

Waterless Steamer)

0.3

i3 0.9

i5 1.3

Single Batch 0.75

Tornado 0.58

©2018 TurboChef Technologies, Inc. Page 2 of 2

TM

Oven Clearances

Verify the oven location has the following clearances on

the top and each side. TurboChef ovens have built-in back

bumpers that allow for the necessary spacing from the oven to

the back wall.

Oven Top Sides

Bullet 5” (127 mm) 2” (51 mm)

C3 4” (102 mm) 2” (51 mm)

Double Batch 2”

(51 mm) 2” (51 mm)

Eco 5” (127 mm) 1” (25 mm)

Encore/Encore 2 5” (127 mm) 2” (51 mm)

Fire 2” (51 mm) 2” (51 mm)

HhB 2 2” (51 mm) 2” (51 mm)

HhC 1618 10” (254 mm) 0” (0 mm)

HhC 2020 10” (254 mm) 0” (0 mm)

HhC 2620 10” (254 mm) 0” (0 mm)

i1 (Panini, Soˇta / Soˇ ta Single

Mag, Waterless Steamer)

5” (127 mm) 1” (25 mm)

i3 19” (483 mm) 2” (51 mm)

i5 19” (483 mm) 2” (51 mm)

Single Batch 2” (51 mm) 2” (51 mm)

Tornado 4” (102 mm) 2” (51 mm)

How the Ovens are Tested

evaluation entails placing the test oven in an environmental

chamber built to capture all emissions escaping during

idle, cooking, and door-open conditions. During the

eight-hour test period, a typical worst-case food item is

cooked continuously, and 100% of condensable and non-

condensable emissions from the product are collected and

analyzed according to the EPA 202 Test Method. At the

conclusion of the test, the total concentration of particulate

matter (emissions) must be less than 5.0 mg/m

3

for the

that measure above the 5.0 mg/m

3

threshold are considered

to produce grease and must be installed under Type I

ventilation, according to International Mechanical Code.

TurboChef ovens are well below the 5.0 mg/m

3

threshold as

shown below.

Contact Information

For questions regarding a ventless installation, email

[email protected]. For questions or concerns

regarding an existing installation, contact Customer Service

at 1.800.908.8726, Option 1.

Ventless Requirement 5 5 5 5 5 5 5 5 5 5 5 5

Emissions 1.35 0.4 2.8 0.32 0.21 0.64 0.89 1.12 1.91 2.4 0.48 0.13

C3 HhB I5 I3 Tornado Sota Eco HhC

2020

HhC

2620

Fire BulletHhC

1618

0

1

2

3

4

5

6

Emissions

mg/m

3

5

1.04

Double

Batch

5

0.52

Single

Batch

Page 11.2