DEPARTMENT OF THE NAVY

HEADQUARTERS UNITED STATES MARINE CORPS

3000 MARINE CORPS PENTAGON

WASHINGTON DC 20350-3000

DISTRIBUTION STATEMENT A: Approved for public release;

distribution is unlimited.

MCO 4790.2

LPC

21 Jan 2016

MARINE CORPS ORDER 4790.2

From: Commandant of the Marine Corps

To: Distribution List

Subj: FIELD-LEVEL MAINTENANCE MANAGEMENT POLICY (FLMMP)

Ref: (a) MCO 4790.25

(b) MCO 4400.150

(c) MCO 3000.13

(d) MCO 3000.11E

(e) MCBUL 3000 (canc: Mar 16)

(f) SECNAV-M 5210.1

(g) SECNAVINST 4410.23

(h) TM-4700-15/1H

(i) MSG 141835Z Nov 14

(j) MCO 5040.6H

(k) NAVMC DIR 5040.6H

(l) MCO 4400.160

(m) MCO 4400.16H

(n) MCO P4400.82F

(o) GPN 2-14

(p) DLM 4000.25-1

(q) MCO 4733.1C

(r) MCO 5100.29B

(s) MCO 5215.1K

(t) MCO 1553.3B

(u) MCO P3500.72A

(v) MCO 4855.10C

(w) NAVMC 4855.1

(x) DoD Directive 4151.18, “Maintenance of Military

Material,” March 31, 2004

(y) MCO 4105.2

(z) MCO 5600.31A

(aa) MCO 4790.24

(ab) MCO 4790.18C

(ac) SECNAVINST 5211.5E

(ad) TM 10793A-OD/1

(ae) TI 10793-ID

1. Situation. In accordance with references (a) through (ae),

this Order outlines the Commandant of the Marine Corps’ (CMC)

MCO 4790.2

21 Jan 2016

2

policy for implementing and managing field level maintenance.

It is designed to integrate requirements, policy, programs, and

procedures to synchronize maintenance and sustainment

activities. When properly implemented, this Policy will

significantly increase equipment readiness and effectively apply

maintenance resources.

2. Cancellation. MCO P4790.2C.

3. Mission. To define and establish Marine Corps maintenance

and maintenance management policies and procedures in order to

improve staff planning, organization, direction, coordination,

and unit readiness.

4. Execution

a. Commander’s Intent and Concept of Operations

(1) Commander’s Intent. Purpose: To enable commanders

to prioritize and manage maintenance resources, increase

equipment availability through a comprehensive maintenance

effort, accomplish the unit’s maintenance mission, improve

overall readiness, and extend the useful life of Marine Corps

equipment. Method: Define and establish uniform management

policies and procedures for ground equipment maintenance

management. End state: Achievement of a ground maintenance

management system that supports and extends operations by

identifying requirements, optimizing maintenance actions,

minimizing resource consumption, and properly managing

information.

(2) Concept of Operations. Accountability and equipment

stewardship is accomplished by the execution of the programs

directed herein and references (a) and (b) and applies to all

levels of leadership. Organizations will perform Field Level

maintenance actions as prescribed in their respective mission

statement and reference (a). Maintenance will be performed at

the lowest unit level possible, consistent with the mission,

nature of the repair, authorized repair parts, tactical

situation, time available, personnel, skill set, logistical

lift, stock positioning of inventory/spares, and authorized

tooling.

(3) Subordinate Element Missions. The Marine Corps

Total Force and supporting establishments responsible for

informal and formal weapon systems and equipment training will

ensure that the provisions of this Order are effected in the

MCO 4790.2

21 Jan 2016

3

administration of the Marine Corps maintenance and maintenance

management programs. All commanders will ensure that the

procedures in this Order are followed. Specific

responsibilities are as follows:

(a) Deputy Commandant, Installations and Logistics

(DC I&L)

1. Serve as the Marine Corps Enterprise Ground

Equipment Manager, responsible for ensuring the roles and

responsibilities identified in this Order are adhered to by the

appropriate stakeholders in order to achieve and maintain strict

equipment accountability and visibility.

2. Serve as the functional advocate for

logistics information systems; ensure these systems are

available and effective to enable Total Life Cycle Systems

Management of ground equipment.

3. Ensure that the Field Supply and Maintenance

Analysis Office (FSMAO) conduct analyses for compliance with

this Order and provide assistance to Marine Corps organizations

as necessary.

4. Coordinate with Commanding General, Training

and Education Command (CG TECOM) to ensure that effective

training programs are implemented on the contents of this Order.

5. Coordinate with Commander Marine Corps

Systems Command (COMMARCORSYSCOM) and affiliated Program

Executive Offices (PEO), in the development of maintenance

policy.

(b) Deputy Commandant, Plans, Policies, & Operations

(DC PP&O). Support field level maintenance in accordance with

reference (a).

(c) Deputy Commandant, Combat Development and

Integration (DC CD&I)

1. Coordinate efforts with DC I&L to ensure

this Order is both implemented and in consonance with current

doctrine.

2. Coordinate with CG MARCORLOGCOM and

COMMARCORSYSCOM/PEO to ensure Total Force Structure Management

System data reflects the most current and accurate information

MCO 4790.2

21 Jan 2016

4

available to enable effective ground equipment maintenance

operations at the field level.

(d) Deputy Commandant, Programs and Resources (DC

P&R). In coordination with DC I&L, CG MARCORLOGCOM and

COMMARCORSYSCOM/PEO, and Marine Forces (MARFORs), to ensure

adequate resources are programmed through the Program Objective

Memorandum process to support Intermediate and Organizational

maintenance and Secondary Reparable (SecRep) replenishment.

(e) Commanding General, Marine Corps Logistics

Command (CG MARCORLOGCOM)

1. Support field level maintenance in

accordance with reference (a).

2. Serve as the Marine Corps Enterprise Ground

Inventory Manager for military equipment, ensuring policies

contained in this directive are supported and that emerging

maintenance and maintenance management practices are addressed

herein.

(f) Commanding General, Training and Education

Command (CG TECOM). Establish entry-level training for ground

maintenance and maintenance management programs. Coordinate

with occupational field advocates to establish intermediate

maintenance and maintenance management programs as appropriate.

(g) Commander, Marine Corps Systems Command

(COMMARCORSYSCOM)/Program Executive Offices (PEO)

1. Support field level maintenance in

accordance with reference (a).

2. Monitor and analyze Logistics Information

Systems to determine trends impacting equipment readiness and

asset availability.

3. Establish and maintain a principal agent

that will serve as the Command’s representative for integrated

product support providing processes, policy, tools, training and

services that enable Program Managers to support the warfighter

and Total Lifecycle Systems Management (TLCSM).

(h) Commanders, Marine Corps Forces. Support field

level maintenance in accordance with reference (a).

MCO 4790.2

21 Jan 2016

5

(i) Commanders

1. Ensure field level maintenance is conducted

on assigned equipment in accordance with reference (a).

2. Ensure maintenance management and

maintenance receive full command support.

3. Establish training programs which address

maintenance management, reliability, and continuous process

improvement targeting equipment operator(s), maintenance

personnel, clerical, and supervisory personnel.

4. Develop and implement a comprehensive

internal maintenance management inspection program to ensure

command policies, procedures, and training are focused on

compliance with maintenance policy.

5. Coordinate and integrate the maintenance

management and maintenance efforts of command activities, and

implement internal control procedures to ensure compliance with

maintenance policy.

6. Coordinate Contracted Logistics Support

(CLS) and warranty support maintenance and sustainment actions

throughout respective areas of operation.

7. Capture and report data used in assessing

performance and sustainment metrics, operational readiness

assessments, costs and ground equipment condition readiness

reporting in accordance with references (c), (d) and (e).

8. Provide feedback on deficiencies or

initiatives within maintenance procedures, concepts and plans,

policy, technical data, equipment design, or logistics chain

processes to the appropriate authority via official channels,

and through participation in the appropriate Operational

Advisory Groups.

b. Coordinating Instructions

(1) Develop, review, update, and implement internal

policies and procedures to facilitate the intent and execution

of this Order.

MCO 4790.2

21 Jan 2016

6

(2) Ensure accurate reporting of requirements, readiness

status and other data into appropriate supporting maintenance

and sustainment systems.

5. Administration and Logistics

a. Recommendations concerning the contents of this Order

are invited and should be submitted to Assistant Deputy

Commandant, Installation and Logistics (LP) attention Logistics

Policy and Capabilities Branch via the appropriate chain of

command.

b. Records created as a result of this Order shall be

managed according to National Archives and Records

Administration (NARA) approved dispositions per reference (f) to

ensure proper maintenance, use, accessibility and preservation,

regardless of format or medium.

c. The generation, collection or distribution of personally

identifiable information and management of privacy sensitive

information shall be in accordance with the Privacy Act of 1974,

as amended, per reference (ac). Any unauthorized review, use,

disclosure or distribution is prohibited.

6. Command and Signal

a. Command. This Order is applicable to the Marine Corps’

Total Force as outlined herein:

(1) To organizations with assigned Table of Organization

and Equipment (T/O&E), including task organized units, except as

indicated below:

(a) Aviation materiel furnished by the Navy which is

subject to policy prescribed by the Chief of Naval Operations.

(b) Medical and dental materiel which are subject to

the policies of Bureau of Medicine and Surgery.

(c) Musical instruments.

(d) Industrial plant equipment.

(e) Government Furnished Materiel (GFM), Government

Furnished Property (GFP), Government Furnished Equipment (GFE),

or Non-Tactical Vehicle, when specific procedures are delineated

in other directives.

MCO 4790.2

21 Jan 2016

7

(f) Research and Development equipment unless

specified by MARCORSYSCOM/PEO and/or the Marine Corps

Warfighting Laboratory (MCWL).

(g) Class V (W), ground conventional ammunition.

(h) Dive equipment.

(2) This Order applies to equipment maintained by the

Marine Corps under approved PBA, Inter-service Support Agreement

(ISSA), Memorandum of Agreement (MOA), Memorandum of

Understanding (MOU), Statement of Work (SOW), etc.

(3) Ground equipment maintenance will be managed as

outlined in this and other directives and manuals in the 4790

series.

b. Signal. This Order is effective upon date signed.

M. G. DANA

Deputy Commandant for

Installations and Logistics

DISTRIBUTION: PCN 10206545100

MCO 4790.2

21 Jan 2016

i Enclosure (1)

Marine Corps Order

(MCO) 4790.2

Field-Level

Maintenance Management Policy

MCO 4790.2

21 Jan 2016

ii Enclosure (1)

LOCATOR SHEET

Subj: FIELD-LEVEL MAINTENANCE MANAGEMENT POLICY

Location: ____________________________________________________

(Indicate location(s) of copy(ies) of this Order.)

MCO 4790.2

21 Jan 2016

iii Enclosure (1)

RECORD OF CHANGES

Log completed change action as indicated.

Change

Number

Date of

Change

Date

Entered

Signature of Person

Incorporated Change

MCO 4790.2

21 Jan 2016

iv Enclosure (1)

TABLE OF CONTENTS

IDENTIFICATION TITLE PAGE

CHAPTER 1 MAINTENANCE MANAGEMENT 1-1

1. GENERAL.......................................1-1

2. RESPONSIBILITIES..............................1-1

3. MAINTENANCE ADMINISTRATION....................1-3

4 SUPPLY SUPPORT................................1-8

5. EQUIPMENT AVAILABILITY........................1-11

CHAPTER 2 MAINTENANCE RESOURCES 2-1

1. GENERAL.......................................2-1

2. TIME..........................................2-1

3. PERSONNEL.....................................2-1

4. MAINTENANCE TRAINING..........................2-1

5. MATERIEL......................................2-1

6. FACILITIES....................................2-2

7. FUNDS.........................................2-2

CHAPTER 3 FIELD MAINTENANCE PRODUCTION 3-1

1. GENERAL.......................................3-1

2. MAINTENANCE PHASES............................3-2

3. MAINTENANCE CYCLE TIME (MCT)..................3-6

4. PREVENTIVE MAINTENANCE CHECKS

AND SERVICES (PMCS)...........................3-8

5. RELATIONSHIP OF PMCS TO CM....................3-10

6. CORRECTIVE MAINTENANCE........................3-10

7. OVERFLOW MAINTENANCE..........................3-15

8. EXCEPTIONAL MAINTENANCE PRACTICES.............3-16

9. ADDITIONAL MAINTENANCE CONSIDERATIONS.........3-18

CHAPTER 4 MAINTENANCE MANAGEMENT PROGRAMS 4-1

1. GENERAL.......................................4-1

3. TRAINING PROGRAM..............................4-1

3. PRODUCT QUALITY DEFICIENCY REPORT (PQDR)

PROGRAM.......................................4-2

4. MODIFICATION CONTROL PROGRAM..................4-2

5. CALIBRATION AND MAINTENANCE PROGRAM...........4-3

6. PUBLICATIONS CONTROL PROGRAM..................4-4

7. CORROSION PREVENTION AND CONTROL (CPAC).......4-4

MCO 4790.2

21 Jan 2016

v Enclosure (1)

TABLE OF CONTENTS

8. DEFERRED MAINTENANCE PROGRAMS..................4-5

9. ENTERPRISE LIFECYCLE MAINTENANCE PROGRAM.......4-6

10. WARRANTY PROGRAM...............................4-6

11. INVENTORY (TOOL) CONTROL PROGRAM...............4-6

12. MINIATURE/MICRO-MINIATURE (2M)

MAINTENANCE PROGRAM............................4-7

13. SAFETY PROGRAM.................................4-8

APPENDIX A MAINTENANCE MANAGEMENT STANDARD

OPERATING PROCEDURES/MAINTENANCE MANAGEMENT

POLICY .....................................................A-1

APPENDIX B SHOP ORGANIZATION............................B-1

APPENDIX C MAINTENANCE PRODUCTION PROCESS............C-1

APPENDIX D ACRONYMS................................D-1

MCO 4790.2

21 Jan 2016

1-1

Enclosure (1)

Chapter 1

Maintenance Management

1. General. Maintenance management integrates requirements,

policy, programs and procedures to synchronize maintenance and

sustainment activities. Maintenance Management plays a critical

role in maintaining unit readiness and, as such, Commander’s

will assign a Maintenance Management Officer (MMO), in writing,

when the billet is not identified by the T/O.

2. Responsibilities

a. Maintenance Management Officer. The MMO serves as

special staff officer to the Commander under either the staff

cognizance of the G-4/S-4 with respect to ground equipment field

level maintenance management. The MMO supports and provides

oversight of the eight functional areas of maintenance

management; maintenance administration, training, records and

reports, PMCS, equipment availability, publications control,

supply support and maintenance programs. The MMO will:

(1) Plan, organize, and coordinate the use of all

maintenance resources within the unit.

(2) Establish, plan and document the execution of the

unit’s maintenance related inspection program in order to

conduct detailed inspections ensure effective maintenance

operations through oversight of the maintenance management

functional areas.

(3) Conduct assessments of the maintenance management

functional areas to ensure effective maintenance operations.

(4) Establish, monitor and coordinate with responsible

officers and maintenance commodity managers to ensure the timely

performance of corrective and preventive maintenance programs.

(5) Coordinate with commodity and maintenance officers

to establish and monitor quality control programs.

(6) Establish evacuation procedures of equipment to

external maintenance activities.

(7) Monitor the documentation of labor hours and tasks

within the Major Automated Information System (MAIS).

MCO 4790.2

21 Jan 2016

1-2

Enclosure (1)

(8) Coordinate with supporting/supported maintenance

activities and ensures compliance with established procedures

and assist in ensuring prompt submission and retrieval of

equipment.

(9) Coordinate with the G-3/S-3 in the balancing of

operational requirements with maintenance scheduling.

(10) Coordinate with the G-4/S-4 in identifying facility

requirements for maintenance operations and training, and

coordinates= the use of available facilities with commodity

managers.

(11) Assist commodity managers in the development and

maintenance of desk-top procedures/turnover files for each

maintenance management functional area.

(12) Establish and monitor procedures for validation and

reconciliation procedures.

(13) Coordinate with commodity managers to ensure the

establishment and administration of the functional areas

outlined below:

(a) Maintenance Administration.

(b) Training.

(c) Publications Control.

(d) Equipment Availability.

(e) PMCS and Corrective Maintenance (CM).

(f) Supply Support.

(g) Maintenance Programs.

(h) Records and Reports.

b. Maintenance Officer/Commodity Manager

(1) Serves as the technical adviser to the commander on

all commodity maintenance functions.

(2) Schedules, directs, and supervises the maintenance

operations for the commodity.

MCO 4790.2

21 Jan 2016

1-3

Enclosure (1)

(3) Coordinates efforts with internal and external

activities for maintenance related operations and issues.

c. Responsible Officer/Equipment Owner

(1) Develops and maintains an effective

scheduled/preventive maintenance program within his assigned

capability.

(2) Coordinates with supporting maintenance activities

for scheduling of equipment requiring preventive/corrective

maintenance.

(3) Responsible for the accurate and timely reporting of

the current operational status of equipment.

3. Maintenance Administration

a. Desk-Top Procedures and Turnover Folders

(1) Desktop Procedures

(a) The frequent change of personnel within units

results in a lack of expertise and continuity in day-to-day

operations. Proper use of desk-top procedures and turnover

folders greatly alleviates this situation and improves the

overall efficiency of an organization. Maintenance Management

Standard Operating Procedures/Maintenance Management Policy

Letter (MMSOP/MMPL) can state the requirements, contents,

details, and the billets that require desk-top procedures and

turnover files.

(b) Each unit/section will prepare desk-top

procedures for each billet involving administrative and

management functions. For example, desk-top procedures will be

established for personnel serving the following billets:

1. Maintenance personnel in key billets

(Quality Control, Maintenance Chief, etc.).

2. Shipping and Receiving.

3. Publications Clerks.

4. Supply Clerks.

5. Dispatchers.

MCO 4790.2

21 Jan 2016

1-4

Enclosure (1)

6. Equipment Readiness.

(c) It is not intended that desk-top procedures be

all inclusive or formalized but, rather, a simple listing of

significant items or notes pertinent to everyday operations

within a particular billet. Normally, they would include such

items as current references, procedures for carrying out

required duties, telephone numbers of individuals who might need

to be contacted, and reports required. Each will prescribe

steps to follow in the accomplishment of all authorized

maintenance or related actions. Procedures will standardize

requirements, actions, and recordkeeping.

(2) Turnover Folders

(a) A turnover folder will include information about

policy, personnel, status of pending projects, references,

management controls, functioning of the section, ways and means

of accomplishing routine as well as infrequent tasks, and other

information of value to an individual assigned to that billet.

The MMSOP/MMPL can outline the requirement, contents, details,

and the billets that require turnover folders.

(b) Folders will be arranged in such a manner as to

permit ease in changing those sections requiring frequent

modification. The degree of detail must be flexible and is

subject to the discretion of organizational commanders. The

important consideration is that the content of folders be

directed towards rendering maximum assistance to the relief.

Turnover folders may be organized by functional area. At a

minimum, turnover folders will be prepared for the following

billets:

1. Maintenance Management Officer.

2. Maintenance Management Chief.

3. Maintenance Officer.

4. Maintenance Chief.

(c) Turnover folders will be titled with the billet

and contain, at a minimum, statements concerning the following:

1. To whom the individual occupying the billet

reports and incumbent billets subordinate thereto.

MCO 4790.2

21 Jan 2016

1-5

Enclosure (1)

2. The mission of the billet (broad billet

responsibilities).

3. The functions involved in accomplishing the

mission (principal action taken).

4. Tasks and basic operations regularly

performed in accomplishing specific functions.

5. List of orders or other directives pertinent

to the billet.

6. List of required reports and dates of

submissions.

7. List the relationship with activities both

in the official and unofficial chain of command, including

unofficial liaison and coordinating functions. Brief statements

concerning the type of matters with which these agencies are

consulted will be included.

8. Contacts within or external to the command,

listing telephone numbers and/or addresses. The purpose served

by the contact will be included.

9. Miscellaneous information will be included.

For example, administrative or operational procedures peculiar

to the billet, such as dual responsibility for certain functions

or limitations in responsibility or authority within particular

functions. Include any other information that might assist in

carrying out the responsibilities.

10. Past, pending, and anticipated projects

will be itemized and kept current. A short resume of past

projects considered unusually important to include, a status

report of each pending project, a brief outline of the project,

and a brief outline of projects considered worthwhile for future

implementations.

b. Standard Operating Procedures and Policies. Marine

Force or Major Command (MajCom) Commanders will designate which

subordinate commands will publish an MMSOP/MMPL. The

instructions contained in the MMSOP/MMPL will be clear and

applicable to the unit level, and detailed to ensure each

subordinate unit can perform its maintenance mission. A MMPL is

warranted when amplification or clarification to an order/

directive or higher level directive (e.g., MMSOP) is required.

MCO 4790.2

21 Jan 2016

1-6

Enclosure (1)

If MMPLs are used they must also include justification as to why

the guidance provided within the order/directive or MMSOP is

inappropriate or requires clarification.

c. Assessments and Inspections

(1) Assessments. Internal assessments are utilized to

measure, preserve and support the unit’s maintenance management

program. Through proper implementation, units will ensure

effective use of resources. These assessments will identify the

unit’s strengths and weaknesses and will assist in evaluating

the command’s current processes, procedures and training

requirements. Below are some guidelines in conducting internal

assessments:

(a) Designate times for internal assessments, (i.e.

on the Training Exercise and Employment Plan (TEEP), and unit

training plan).

(b) Use or incorporate HQMC or HHQ checklist

questions in your unit’s internal assessment.

(c) Involve Marines in the process; invite HHQ or

external support if needed. The quality and effectiveness of

the assessment is reliant on subject matter expertise and

experience.

(d) Read and understand the references in the

checklist (seek assistance if unsure): be critical, thorough and

systematic.

(e) Document discrepancies and establish corrective

actions and follow on review of discrepancies.

(f) Pick a sample of items to review (you don’t need

to look at 100%).

(g) Conduct causative research as needed.

(h) Develop and execute a plan to correct records

and procedures.

(i) Follow MMSOP or MMPL to report corrections.

(j) Update desk-top procedures and turnover folders.

MCO 4790.2

21 Jan 2016

1-7

Enclosure (1)

(k) Create and follow-up on corrective action plans

with a focus on discrepant areas from the initial assessment.

(l) Retain internal assessment results.

(m) Verify that Marines have access to required

MAIS.

(n) The effectiveness of reconciliations; ensure

they are comprehensive and timely.

(2) Inspections. Inspections are one of the principal

means available to unit commanders to ascertain whether planning

and organization are sound and their staffs are functioning

effectively. Inspections are either formal or informal and can

be performed by internal or external sources. When conducted

inspections should document, corrective actions initiated

through follow on review of discrepancies. Local policy will

dictate the frequency of the required inspections. The

following are typical inspections that maintenance management

officer may be subject to:

(a) Informal Inspections. Informal inspections may

examine the unit or certain areas of the unit’s activity to the

same extent as a formal inspection or to any lesser extent. A

spot-check inspection of equipment or personnel in the conduct

of routine operations is an example of the simplest of the

informal inspections. Inspection checklist may be prescribed;

however, are not necessary. Results can be communicated written

or orally.

(b) Formal Inspections

1. Field Supply and Maintenance Analysis Office

(FSMAO). Scheduled FSMAO analysis of field units are designated

as formal analyses. Reports are filed at the conclusion of each

analysis. The FSMAO’s mission includes identifying and

reporting deficiencies in supply and maintenance operations,

compliance to policy, and recommending remedial action. In

addition to the formal analysis, the unit commander can request

assistance in specific problem areas. Details of the FSMAO’s

mission and responsibilities are found in reference (l).

2. Inspector General of the Marine Corps

(IGMC). The IGMC ensures that unit’s maintain the highest level

of readiness, effectiveness, discipline, efficiency, integrity,

morale, economy, and ethics encouraging public confidence. This

MCO 4790.2

21 Jan 2016

1-8

Enclosure (1)

program is administered under the Marine Corps Readiness

Inspections and Assessments references (j) and (k). The IGMC

conducts inspections, investigations, or inquiries into any and

all matters of deemed important within a command and includes

the Commanding General’s Inspection Program and Command

Inspection Program (CIP).

4. Supply Support. Effective supply support requires close,

and continuous, coordination between the MMO, supply officer,

equipment owner and maintenance officer to ensure:

a. Requisitioning. Standardized submission and

requisitioning procedures are established for the unit through

the MAIS that supports and ensures:

(1) Repair parts and maintenance related supplies are

requisitioned in accordance with time standards outlined in

reference (m). The application of the time standard will be

applied from identification of the equipment problem or stock

list item shortage to submission into the MAIS.

(2) Requisition priorities are equal to, or lower than,

the priority of the associated maintenance repairs being

conducted and consistent with the mission essentiality of the

item being requisitioned.

b. Validation and Reconciliation. The preservation and

management of resources through implementation of effective

validation and reconciliation procedures ensures repair parts,

secondary reparables, components, and collateral equipment,

unless properly controlled, represent a continuing drain on the

unit’s resources. Effective validation and reconciliation

procedures will ensure that requirements are known, promptly

processed, and applied when received.

(1) Validation. The process used to confirm repair part

requirements. It involves confirmation of requirements that are

still needed, cancellations, receipts, scrounges, and current

status. When confirming needed requirements, the customer must

ensure that the items have been made known, still exist, and are

resident in the supply system.

(a) Ensure that all receipts, cancellations, and

scrounges have been identified and that required transactions

have been submitted and processed within the MAIS.

MCO 4790.2

21 Jan 2016

1-9

Enclosure (1)

(b) Ensure all parts requirement can be associated

to open requests.

1. Weekly

a. Deadline operational status of readiness

reportable equipment against the MAIS.

b. Readiness reportable equipment report

within the MAIS to ensure operational statuses is correct.

c. Supporting maintenance activities for

unit-owned and temp loaned equipment that is in the maintenance

cycle.

d. Review readiness, management and

production reports within the MAIS to identify the following:

(1) Recurring Errors. Trends in data

input errors should prompt a review of a unit’s procedures or

discussions with the Logistics Systems Coordination Office

(LSCO) concerning possible system problems. Any program/system

issues will be identified to the chain of command.

(2) Requisitioning Delays. Comparing

the date of the status, the approval date, and document

transaction run date will reveal any delays in processing

requisitions and identify the source of the delay.

2. Monthly

a. Unit readiness report within the MAIS

with the T/O&E, and reference (e) to ensure all readiness

reportable ground equipment reflects the correct authorized

quantity.

b. Unit readiness report within the MAIS

and the Mechanized Allowance List (MAL) with the equipment

physically on-hand to ensure "possessed" quantities are reported

correctly.

c. Any program/system issues will be

identified to the chain of command.

(2) Reconciliation. Reconciliation is the process used

to ensure that validated requirements are properly logged within

the MAIS.

MCO 4790.2

21 Jan 2016

1-10

Enclosure (1)

(a) Proper reconciliation between the maintenance

and supply sections.

(b) Continuous monitoring of requisitions.

(c) Commodity Manager/Shop/Maintenance Officer.

After the weekly validation, the commodity manager or

shop/maintenance officer or chief will accomplish the following

with the MMO and Supply:

1. Ensure that the supply status provided is

current, acceptable, and understood. Request the supply office

clarify any status that is not understood or does not

sufficiently correspond to requisition priority.

2. Identify corrections and necessary updates

and assist Responsible Officers, maintenance commodity sections,

and the supply section to correct and update the MAIS.

c. New Equipment Fielding. Fielding of new equipment

involves coordination throughout the using unit amongst the

supply officer, gaining responsible officer and maintenance

commodity. The Commanding Officer will place newly fielded

equipment into service in accordance with the fielding plan

prior to conducting operations. The MMO will ensure:

(1) Fielding plans (FP) are reviewed to ensure

maintenance resource planning is coordinated.

(2) Validate or initiate the equipment’s life-cycle

attributes within the MAIS to include: warranty, configured

status validated, PMCS interval validated, PMCS scheduled

established, counter established, and counter reading entered.

d. Demand Supported Items (DSI). Monitor approved DSI

inventories and strict adherence to reference (b), to ensure

proper accounting and capture of class IX (repair parts) through

the MAIS.

e. Funds. Whether in terms of hard dollars, budgets, or

operating targets, funds are not directly seen by the MMO or

maintenance sections. The adequacy of funding is indicated in a

maintenance section by the availability of repair parts, tools,

and other maintenance related supplies. Even though the impact

of funding is indirect, the role of the MMO is vital.

Coordination ensures the input of maintenance requirements for

all commodity areas.

MCO 4790.2

21 Jan 2016

1-11

Enclosure (1)

(1) In the budgeting process the MMO ensures that the

data collection is accurate. All costs of repair parts will be

captured when funds are expended. Field budget guidance and

staff coordination with G-3/S-3 and G-4/S-4 will provide the

information regarding the tempo of future operations, logistic

commitments, and new equipment receipts. Using this information

will assist commodity and maintenance sections in expressing

requirements while fulfilling staff responsibility for input to

the budget process.

(2) Planning. Information will be captured routinely in

the MAIS or local system routinely on the obligation and

subsequent expenditure of funds.

(3) Control. Once allocated, funds must be controlled.

There are numerous regulations concerning obligation authority.

The MMO’s responsibilities include providing staff advice on

internal allocation/reallocation, ensuring that funds obligated

for maintenance resources are applied in the best manner, and

ensuring that periodic fiscal reviews are conducted. Below are

two examples that best illustrate the control function of the

MMO:

(a) The MMO fulfills the control function and meets

a staff responsibility by coordinating with the supply,

maintenance and fiscal officers and then presenting the

commander with the necessary information to decide on the

allocation/reallocation of funds, cancellation of requisitions,

or request for additional funds.

(b) The MMO, in conjunction with the unit’s supply

and fiscal officers and in coordination with the command’s

comptroller, must develop the unit’s job order number structure

allowing information collection and permitting sound command

decisions based on readily available information.

5. Equipment Availability. The MMO advises the commander on

all matters relative to equipment readiness and the impact to

the unit’s mission. Timely and accurate reporting of all

equipment and its operational status shall be executed in

accordance with references (b), (c), (d), and (e).

MCO 4790.2

21 Jan 2016

2-1 Enclosure (1)

Chapter 2

Maintenance Resources

1. General. Maintenance resources are time, personnel,

maintenance training, materiel, facilities, and funds.

Commanders influence the allocation of maintenance resources

through budget submissions, T/O revisions, and T/E changes.

2. Time. Commanders at all levels must plan time for the

effective accomplishment of maintenance operations. Doing so

increases command attention on the importance of maintenance and

facilitates increased equipment and personnel availability.

Maintenance Officers, Chiefs and MMOs must maintain awareness of

time as a resource and shall continuously monitor to ensure

maintenance and non-maintenance activities are synchronized in

an effective manner.

3. Personnel. Commanders will ensure the proper allocation of

human resources to accomplish all maintenance tasks in support

of an organization’s assigned equipment. The allocation will

address the required manning levels and skill sets. Equipment

to manpower reviews will be continuous and official Table of

Organization and Equipment Change Request (TOECR) will be

submitted when required.

4. Maintenance Training. A critical aspect of personnel

resourcing, in support of maintenance operations, is the

effective management and oversight of maintenance training.

Maintenance Officers, Chiefs and MMOs must continuously evaluate

mission requirements and tables of organization against on-hand

personnel training readiness levels. Doing so ensures that

appropriately trained personnel exist to support maintenance

requirements. Effective planning and forecasting is required

in ensuring that training remains aligned to mission

requirement. Maintenance personnel should become familiar with

training systems and shall coordinate closely with unit training

personnel to ensure proper scheduling and effective execution of

maintenance training. Maintenance personnel and MMOs will

utilize applicable Training and Readiness (T&R) Manuals as

guides to ensure training readiness is maintained and provided

in the most appropriate method.

5. Materiel. Consists of all materiel items required to

support the operation and maintenance of military equipment.

Materiel to be considered in resource planning include, but are

not limited to, Class IX repair parts, Class III fluids and

MCO 4790.2

21 Jan 2016

2-2 Enclosure (1)

lubricants, required tools, test or support equipment, and

technical publications. Maintenance personnel shall

continuously consider and plan for materiel requirements

throughout phases of maintenance.

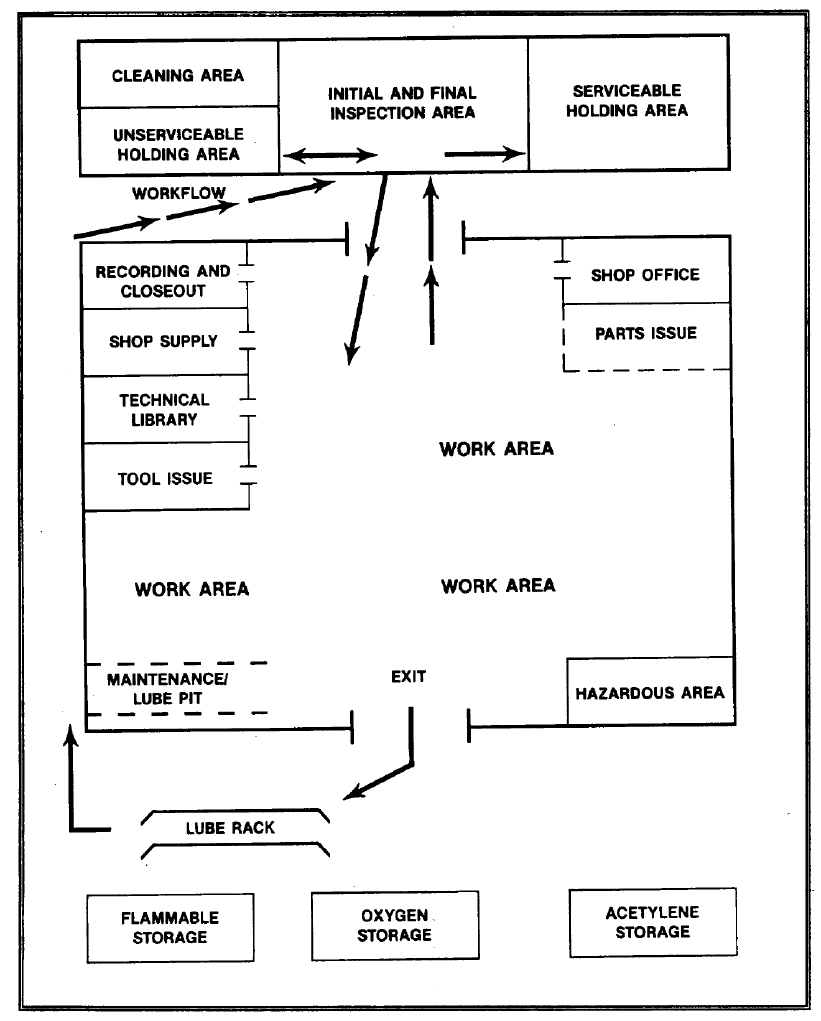

6. Facilities. Facilities are real estate or structures that

provide support for missions, functions, and tasks. It is

important that land and facilities be accorded the same

commitment, concern, and support as other war fighting systems.

The staff functions and considerations and factors effecting

site selection, shop layout, and organization are established in

Appendix B (Shop Organization).

7. Funds. The funding of maintenance at the field level is

achieved by accurate budget planning. Budget submissions will

account for forecast based on historical demand for repair

parts, future estimates for operations and exercises,

appropriate materiel forecast, new equipment fielding, aged

equipment and average cost of maintenance programs.

MCO 4790.2

21 Jan 2016

3-1 Enclosure (1)

Chapter 3

Field Maintenance Production

1. General. Maintenance involves those actions taken to

restore or retain materiel in serviceable or operational

condition. Maintenance tasks are grouped into two types,

preventive and corrective. Preventive maintenance is the

practice of maintaining equipment on a regular schedule based on

elapsed time or counter reading. Corrective maintenance

involves those actions to restore materiel to a serviceable

condition.

a. Maintenance Authority. A unit’s authority to perform

maintenance tasks corresponds directly to the assigned

capabilities and available resources for accomplishment of the

mission. Units are not authorized to conduct maintenance

outside of their assigned capabilities except when coordinated

through the supporting/supported relationship or as outlined in

reference (a). An organization’s assigned personnel and

authorized equipment form the foundation of the assigned

capability. The concept of operations for a given mission that

establishes the supporting and supported relationships will

influence and further refine the assigned capability. Reference

(a) is the principal document that provides maintenance

authority and defines maintenance capability within a two level

of maintenance concept:

b. Levels of Maintenance (LOM). Field and Depot. The

distinction between field and depot LOM is based on the

maintenance tasks performed, within each LOM and as communicated

through the Source Maintenance Recoverability (SMR) code. The

levels of maintenance are summarized below however; reference

(a) is the principal document that establishes the levels of

maintenance for the Marine Corps.

(1) Field LOM. Field maintenance is any maintenance

that does not require depot maintenance capability and is

performed by equipment operator(s) and mechanics/technicians

within Marine Corps organizations and activities, and/or by

approved commercial/contract sources. Maintenance tasks

performed within the field LOM are categorized as organizational

or intermediate. A unit may perform any field maintenance tasks

for which it is manned, trained and equipped. Units are not

authorized to conduct maintenance outside of their assigned

capabilities. However, supported and supporting unit commanders

MCO 4790.2

21 Jan 2016

3-2 Enclosure (1)

are authorized to coordinate in order to ensure the most

effective use of maintenance resources within their respective

capabilities, and will incorporate local standard operating

procedures to ensure the same. Additionally, commanders must

consider their impacts not only to their own operations and

resources, but also on those of their supporting/supported

units.

(2) Depot LOM. Maintenance actions taken on material or

software involving the inspection, repair, overhaul, or the

modification or reclamation (as necessary) of weapons systems,

equipment end items, parts, components, assemblies, and

subassemblies that are beyond field maintenance capabilities,

and/or are authorized and directed by HQMC.

2. Maintenance Phases. Appendix C provides a series of steps

depicting a logical sequence necessary to complete the various

types of maintenance functions, which are described below.

a. Acceptance Phase. The acceptance phase is the initial

step of the maintenance production process. It consists of

inspection, scheduling, and assignment within the maintenance

activity.

(1) Inspection. The purpose of the acceptance

inspection is to verify that the equipment is complete and

prepared for the required maintenance service and is conducted

upon initial receipt by the maintenance activity. The

procedures to be followed in the acceptance inspection are as

follows:

(a) Determine that the equipment is complete by

locating, identifying, and inventorying equipment and its

components and ensuring that appropriate operator maintenance,

including cleaning, configuration and application of appropriate

modification has been performed. Remove and store collateral

materiel and annotate accompanying documentation unless

collateral equipment is required during the active maintenance

phase. Equipment incomplete or not properly prepared by the

unit or activity requesting maintenance should be reported to

the owning unit via the MMO.

(b) Verify the request for maintenance has been

properly prepared in order to facilitate any maintenance

requirements.

MCO 4790.2

21 Jan 2016

3-3 Enclosure (1)

(c) Accept the equipment for the required service.

(d) Assign a production priority for use within the

maintenance section. This priority will be based upon the

Urgency of Need Designator (UND) assigned and as outlined in

reference (m).

(2) Acceptance Scheduling. The purpose of acceptance

scheduling is to have equipment requiring maintenance arrive at

the maintenance facility at or after the time that the required

maintenance resources are available. This procedure allows the

equipment owner maximum operational use of this equipment while

avoiding needlessly large concentrations of equipment awaiting

maintenance at the maintenance facility. Acceptance scheduling

applies to maintenance functions performed at the field level.

To be effective close coordination between the equipment owner

and the maintenance section is required. Acceptance scheduling

normally applies to all PMCS, modification, calibration, or

routine repairs. Procedures for acceptance scheduling are as

follows:

(a) Initiation of requests through local procedures.

(b) Validate and or assign the UND in accordance

with reference (m).

(c) Acceptance by the maintenance section includes

establishment, when appropriate, of the date for delivery of the

equipment for the required service.

(d) Tentative scheduling of the equipment to a

specific maintenance section/shop within the maintenance

activity.

(e) Determining the parts required for the service

and initiating requisitions to ensure availability of parts at

the time of the service.

(3) Shop Assignment. The assignment of equipment to a

specific maintenance section/shop within the maintenance

activity occurs upon completion of the acceptance inspection and

scheduling, when appropriate. In maintenance activities

comprised of only one maintenance shop, shop assignment occurs

at the time of acceptance of the equipment during the acceptance

inspection. Procedures to be followed in the shop assignments

are as follows:

MCO 4790.2

21 Jan 2016

3-4 Enclosure (1)

(a) Identify the type of shop to perform the

required service.

(b) Review the workloads and available resources of

individual shops within the maintenance section and determine

which shop should be assigned responsibility for repairs.

(c) Assign the responsibility to a specific

maintenance shop. When assigning, always consider the UND

assigned to ensure that the equipment readiness of supported

units is not impaired.

(d) Assign the DSI required for the service to

ensure availability at the time of induction.

b. Induction Phase

(1) Induction is the physical delivery of the equipment

requiring service to the maintenance activity.

(2) Induction of equipment into a specified maintenance

activity must be by the priority established in the equipment

acceptance phase.

c. Active Maintenance Phase. Production actions performed

following induction of the equipment into a maintenance shop

constitute the active maintenance phase and the beginning of the

repair process. This phase is performed in a sequence of

logical steps designed to ensure that the required services are

conducted in an efficient and effective manner. During this

phase, continual emphasis is placed on quality control of the

actions and tasks performed. The frequency of quality control

inspections will depend on the skill and experience of the

individual technicians or mechanics and the overall complexity

of the actions. The steps to be followed in the conduct of

active maintenance are described in the following:

(1) Inspection. Maintenance personnel assigned to

perform the service will perform a detailed inspection of the

equipment upon its induction into the maintenance activity.

This inspection serves as a basis for the performance of the

maintenance and includes verifying all equipment records

associated with the required service is current.

(2) Preparation. Preparation includes the assembly of

the appropriate technical publications and other technical

MCO 4790.2

21 Jan 2016

3-5 Enclosure (1)

information, support equipment, and Test Measurement and

Diagnostic Equipment (TMDE) to perform required service.

Adequate preparation reduces the actual time required to perform

the maintenance and ensures that maintenance actions are not

initiated when the required resources are not available.

(3) Performance. Maintenance tasks such as PMCS, CM,

calibrations, and modifications will be performed per the

appropriate technical publication by qualified personnel.

(4) Quality Control (QC). QC requires a complete

inspection of equipment to determine completion of maintenance

actions and update of equipment records within the MAIS (if

required). Equipment will be inspected by assigned quality

control personnel. Equipment not performing satisfactorily will

be rejected and recommendations made for further maintenance

action. Acceptable performance results in the completion of the

active maintenance phase and the movement of the equipment to

the closeout phase.

d. Maintenance Closeout Phase

(1) The closeout phase of the maintenance process

commences when equipment has been repaired or disposition has

been executed. Maintenance personnel will ensure that the

closeout process is accurate, complete, and coordinated.

(2) The closeout phase requires close coordination with

owning unit personnel to ensure that they are notified as soon

as the equipment is ready for pickup. Special packaging,

preservation, transportation, and shipping requirements must be

taken care of at this time. Adhering to the UND timelines

established in reference (m) the using unit must make every

effort to pick up completed equipment promptly.

(3) In the closeout phase, owning unit maintenance and

supply personnel must ensure that equipment records

accountability records have been updated; this includes but not

limited to ensuring proper accounting of class IX, documenting

maintenance tasks performed, level of effort (time) to conduct

the tasks, and updating of equipment readiness status.

3. Maintenance Cycle Time (MCT). Maintenance Cycle Time is the

period of time covered from the initiation of maintenance

actions until repairs and maintenance records are complete.

Maintenance cycle time begins when the equipment is

MCO 4790.2

21 Jan 2016

3-6 Enclosure (1)

inducted/accepted into the maintenance activity and ends upon

the closeout.

a. Maximum Maintenance Cycle Time (MMCT). The MMCT is the

maximum prescribed time an asset is to remain in the maintenance

cycle. The prescribed time is established as a decision making

threshold. Every asset type has a unique maintenance cycle time

and therefore maintenance managers will focus on minimizing

maintenance cycle times and will only reach the maximum by

exception.

(1) End Items. An end item is a full equipment

capability set. It includes all components assembled and

configured to form a specific mission. An end item is a class

VII supply item.

(a) MMCT for end items will be 120 days CONUS / 150

days OCONUS.

(b) MMCT for an end item is measured from the date

the organizational level maintenance activity receives the item

for maintenance until all maintenance actions are close. This

time includes any days the end item or one of its component

items is evacuated to an intermediate maintenance activity.

(2) Component Items. Component items are assets that

are configured to end items. A component item can sometimes be

categorized as an end item, if it is not configured under a

different end item. An example is a truck. A truck can be an

end item or it can be a component of a system. A component item

is also a class VII supply item.

(a) MMCT for a component items is 60 days CONUS / 90

days OCONUS.

(b) MMCT for a component item is measured from the

date the maintenance activity receives the item in for

maintenance until all maintenance actions are closed. In cases

where the Intermediate Maintenance Activity (IMA) has received

an end item, the component item MMCT applies. The owning

organization is capturing the MMCT for the end item.

(3) Secondary Reparable (SecRep). A SecRep is a class

IX supply item that is not consumable. It is repaired and

returned to a class IX supply block.

MCO 4790.2

21 Jan 2016

3-7 Enclosure (1)

(a) MMCT for a SecRep is 45 days CONUS / 60 days

OCONUS.

(b) MMCT for a SecRep is measured from the date the

IMA receives the item in for maintenance until all maintenance

actions are close.

b. Expiration of MMCT. When the MMCT expires or

documentation shows that repairs cannot be completed within the

MMCT, the following action will be followed:

(1) Organizational Maintenance Activity Actions

(a) If the asset is not evacuated to an IMA, the

organization will submit an official request for disposition per

references (n) and (o) on controlled items. Include in the

remarks paragraph of the disposition report all actions taken to

obtain required parts.

(b) Other-than-controlled items will be disposed of

per appropriate orders and reference (i).

(c) Exceptions. Maintenance cycle times can be

extended when directed via disposition instruction. Commanders

may extend maintenance cycle times for any unique scenarios that

are not due to supply support or maintenance resources, which

are covered by official request for disposition.

(2) IMA Actions (End Items and Component Items)

(a) IMAs will submit an official request for

disposition per references (n) and (o) on controlled items.

Include in the remarks paragraph of the disposition report all

actions taken to obtain required parts, including follow-up

message traffic to the Marine Corps Logistics Command

(MARCOLOGCOM).

(b) Other-than-controlled items will be disposed of

per appropriate orders and reference (i).

(c) Exceptions. The supporting maintenance

activity’s maintenance officers are authorized to extend the

MMCT when directed via disposition instruction. Commanding

officers of the owning organization must approve all MMCT

extensions for any unique scenarios that are not due to supply

MCO 4790.2

21 Jan 2016

3-8 Enclosure (1)

support or maintenance resources, which are covered by official

request for disposition.

(3) IMA Actions (SecReps)

(a) Supporting maintenance activities will conduct a

review with the Reparable Issue Point (RIP) manager to determine

the appropriate action.

(b) RIP managers are responsible for all requests

for disposition of SecReps or for initiating the Material

Returns Program (MRP).

(c) Exceptions. The supporting maintenance

activity’s maintenance officers are authorized to extend the

MMCT when directed via disposition instruction. RIP managers

must approve all MMCT extensions for any unique scenarios that

are not due to supply support or maintenance resources, which

are covered by official request for disposition. Each extension

will be no longer than 30 days, at which time the need will be

revalidated prior to any subsequent extensions.

c. Documentation

(1) Commanders shall establish local procedure for the

extension of MMCT.

(2) Personnel authorized to extend MMCT shall be

appointed in writing.

(3) Maintenance Officers and Maintenance Management

Officers will ensure that all approved extension letters and/or

extension documentations be added within the MAIS. At a

minimum, the record will be annotated to explain the reason the

cycle was extended, who approved the extension, and the length

of the extension.

4. Preventive Maintenance Checks and Services (PMCS). PMCS is

a sub-function of field maintenance and is performed by

equipment operator(s) and maintenance personnel; it includes

servicing, adjustment, and tuning for the purpose of maintaining

equipment in an operationally ready condition. PMCS is

condition based and shall be accomplished by systematic

inspection, detection, and correction of failures as set forth

in applicable equipment technical publications.

MCO 4790.2

21 Jan 2016

3-9 Enclosure (1)

a. Scheduled PMCS. Scheduled PMCS are maintenance tasks

that are required to be scheduled; the performance will be by

trained maintenance personnel and assisted by the equipment

operator(s) as required.

(1) Intervals are established for equipment at the

program office level and within the MAIS in accordance with

applicable technical publications.

(2) Scheduled PMCS is the responsibility of the

equipment owner or unit using the equipment.

(a) Commanders are authorized to increase the

frequency for scheduled PMCS, when operating conditions warrant.

(b) PMCS will be scheduled and recorded within the

MAIS.

(c) For equipment with no PMCS interval designated,

the commanding officer will designate an interval not to exceed

annual.

(d) Equipment not under a warranty period may have

PMCS intervals deferred when placed in administrative storage or

administrative dead-line per this Order. Equipment under

warranty will have the respective technical publication reviewed

to determine appropriate procedures for inclusion into an

administrative storage program.

(e) Commanders are not authorized to deviate beyond

the minimum established schedule(s) for the conduct of PMCS

tasks. When tasks are identified that are either redundant and

conditions warrant change Commanders will recommend changes to

these tasks to the appropriate program manager via NAVMC 10772

or PQDR.

(3) PMCS tasks conducted by equipment operators are not

required to be scheduled or captured within the MAIS.

b. Equipment Counters. Equipment counters are used to

measure the operating intervals of equipment. Equipment

requiring a measurement of use (i.e. hours, miles or rounds)

will be configured with a counter(s) within the MAIS.

Commanders will ensure equipment counters are updated and

reconciled against the MAIS at a minimum of monthly or as

operational conditions warrant.

MCO 4790.2

21 Jan 2016

3-10 Enclosure (1)

5. Relationship of PMCS to CM. The objective of PMCS is to

reduce or identify CM requirements and increase the useful life-

cycle of equipment. When defects are identified a decision must

be made whether to perform the CM independently or in

conjunction with the PMCS. Equipment requiring evacuation for

CM shall be closely coordinated between the using unit and the

supporting maintenance activity. Time, distance between the

organizations, available personnel, quantity and nature of the

equipment involved are factors to be considered in determining

if the owner or the supporting maintenance activity will perform

PMCS.

6. Corrective Maintenance. CM consists of all maintenance

actions performed, as a result of a failure, to restore

equipment to an operational condition. The CM process commences

when equipment is reported as requiring CM. It terminates when

equipment is either restored to a serviceable condition,

determined not reparable through disposition instructions. The

owning unit is responsible for the timely performance of all CM

actions within its responsibility. The designated supporting

maintenance activity is responsible for the timely performance

of all CM actions exceeding the owning unit’s

capacity/capability. CM will be performed per the procedures

established in appropriate equipment technical publication.

Deviations from these procedures must be minimized and

consistent with the effective performance of the specific

maintenance action. Recommendations for the improvement of

established CM procedures will be forwarded to the appropriate

PM via NAVMC 10772, to include the challenge of an SMR code. CM

process is contained in Appendix C.

a. Field Maintenance – Organizational Category

(1) Field maintenance in the organizational category is

normally performed by the owning organization with its assigned

capabilities and resources. This is commonly referred to as

organizational maintenance.

(2) Organizations will perform all CM tasks that are

within their assigned capabilities/responsibilities. If an

asset requires maintenance that exceeds the assigned

capability/capacity, the items will be evacuated to the

supporting maintenance activity.

MCO 4790.2

21 Jan 2016

3-11 Enclosure (1)

(3) Organizations will replace defective secondary

reparable components by conducting an exchange with the

supporting RIP. SecReps with a source maintenance and

recoverability (SMR) code with an “O” in the 3rd character

position are authorized to conduct an exchange. SecReps with an

SMR code of “F”, “H”, “D”, or “L” in the 3rd character position,

require the end item to be evacuated to the appropriate

supporting maintenance activity.

b. Field Maintenance – Intermediate Category. Field

maintenance in the intermediate category is normally performed

by an organization that has been established and assigned a

mission to perform maintenance tasks that require a higher level

of technical training, specialized tools and/or facilities.

Command maintenance support relationships must define the link

between supporting maintenance and supported organizations. A

typical example is the Marine Logistics Group’s Maintenance

Battalion providing general support (GS) intermediate

maintenance to the supported Marine Expeditionary Force (MEF).

Regardless of the nature of the supporting/supported

relationship, the procedures for conducting intermediate

maintenance will be the same.

(1) Military Equipment

(a) Equipment will be accepted into the supporting

maintenance activity with the priority assigned by the owning

organization. Authorized personnel in the supporting

maintenance activity are authorized to approve Urgency Need

Designator (UND) “A”, “B” and “C” requisitions consistent with

the originating unit’s request and reference (M).

(b) Supporting maintenance activities will replace

defective secondary reparable components on military equipment

by conducting an exchange with the supporting RIP. Supporting

maintenance activities are authorized to conduct the exchange of

SecReps with an SMR code of “F” and “H” in the 3rd character.

If the secondary reparable has a “D” or “L” in the 3rd character

position, the unit must request disposition.

(2) Secondary Reparables (SecReps). SecReps are

generally categorized as Line Replacement Units (LRUs) and Shop

Replacement Units (SRUs). An LRU is a direct sub-assembly to

military equipment. An SRU is a direct sub-assembly to an LRU.

A systematic SecRep exchange is required, no matter if the item

is an SRU being exchanged against and LRU or an LRU being

MCO 4790.2

21 Jan 2016

3-12 Enclosure (1)

exchanged against an end item. The process and system

requisition flow will follow the same general procedures.

Typically SRUs are only exchanged by SecRep repair activities

while performing maintenance on LRUs.

(a) SecRep Repair Field. Field LOM on SecReps

consists of testing and verification, verification of

modifications, software restoration, tuning and alignments,

fault isolation, replacement of defective pieces, parts and

subassemblies. The authorized LOM on SecReps within the MARFORS

will not exceed the field LOM as defined by this Order and

reference (a). The intent is to rapidly perform repairs and

return serviceable components to RIP stocks in a condition code

“A” status.

(b) SecRep Repair Depot. Depot LOM on SecReps

consists of in depth testing and verification, repair and

restoration, overhaul and rebuild of a component and its

subassemblies. Depot LOM on SecReps often requires specialized

TMDE and tools, the intent of depot LOM on SecReps is to restore

an item to a like new/OEM specification. Depot LOM is provided

by Third Party Logistics (3PL) providers, Original Equipment

Manufacturers (OEM) and DoD depot maintenance.

(c) Supporting Maintenance Activity/Reparable Issue

Point (RIP) Relationship. LSCOs within the MARFORS will ensure

these systematic relationships are established within the MAIS.

(d) SecRep Maintenance Capacity. Capacity

management will be achieved through the observation of

production, throughput over time, and resource availability,

which will guide management decisions. Analyses will be made on

each asset type/group (NIIN level) while considering the

following key variables.

1. Throughput Ratio. This is the ratio of the

number of unserviceable assets received into the work section

compared to the number of serviceable assets returned to stocks;

over a time span long enough to form a production analysis.

(Will differ depending on the asset group)

2. RIP Stock Levels/Backorders. Assets that

have customer backorders registered at the RIP, or low stock

levels require thorough capacity review. RIP managers and

maintenance officers will collaborate when these variables

exist.

MCO 4790.2

21 Jan 2016

3-13 Enclosure (1)

3. Maintenance Cycle Times. Maintenance cycle

times are variables that will aid capacity managers in

determining the volume of assets that can be effectively managed

over time.

4. Repair Parts Availability. The availability

of consumable and reparable supplies that support SecRep

maintenance is a variable that maintenance officers will

continuously monitor.

5. SecRep Budgets. RIP managers will routinely

communicate fiscal concerns to maintenance officers to better

inform capacity management decisions.

6. ME Readiness. ME readiness is addressed by

maintaining adequate stock levels at the RIP to meet demands.

However, when backorders/low stock levels exist on multiple

asset types, ME readiness will aid in establishing priorities

for capacity management. RIP managers and maintenance officers

will collaborate when these variables exist.

7. Manpower. Manpower analyses will consider

the availability of trained personnel who possess the

appropriate core competencies. Maintenance officers must ensure

manpower issues are considered and mitigated to the maximum

extent possible.

8. Workspace. Shortage of workspace

(Shop/floor/bench) is a variable that can have a negative impact

on capacity. Maintenance officers must ensure workspace issues

are considered and mitigated to the maximum extent possible.

(e) SecRep Source of Repair Decision. Decisions in

determining source(s) of repair at the RIP are inherently the

responsibility of the RIP manager. Backorders, stock levels,

and warranty information will have an impact to the source of

repair decision. The following considerations will aid in the

determination of source of repair:

1. Warranty, if applicable, and within the

scope of coverage.

2. Capabilities of the supporting maintenance

activity.

MCO 4790.2

21 Jan 2016

3-14 Enclosure (1)

3. Maintenance capacity of the supporting

maintenance activity (current throughput ratios and average

maintenance cycle times).

4. Results of initial testing, if applicable.

(field or depot level maintenance requirements). Some assets

will require a repair source determination that can only be

obtained by limited testing (e.g. engine tested on a

dynamometer). If the asset has no obvious defects (e.g. visible

engine block damage) and the local maintenance organization is

capable of performing a test, it will do so prior to making the

repair source decision. The purpose of the initial test is to

determine the required LOM. Initial testing will be documented

on the system generated maintenance record within the MAIS. It

is not cost effective to exercise MRP, 3PL, or OEM actions on

SecReps without testing and screening for field level repair

candidates when the capability exists. Source of repair

decision should normally be completed on the same day the

unserviceable item is received at the RIP. This process will

not exceed 5 days and inclusive of the MMCT. The intent is to

allow time for initial testing, when necessary (e.g. an asset is

scheduled for a dynamometer test on day 5 and found to be within

the field LOM and can be accepted). If the item under test is

found to be outside the scope of the field LOM, maintenance

officers will ensure the MAIS is documented accordingly to

capture the resources used, and testing performed (e.g., accept,

record, and close) and inclusive of the MMCT.

(f) SecRep Configuration. Approved configuration

checklists are published by MARCORLOGCOM. SecReps will be

inspected for configuration by trained maintenance personnel

upon arrival to the RIP, regardless of the source of repair

decision.

(g) Close out Condition Code Assignment(s). Assets

restored to a serviceable condition will be closed out with a

serviceable status ready for issue. Unserviceable assets will

be returned to the RIP in a condition code (F) status for

processing under the following conditions:

1. Uneconomical to Repair. A SecRep is

considered uneconomical to repair if the repair cost exceeds 45%

of the replacement cost, and a replacement is obtainable.

During combat operations, time and stock posture will be

considered over cost of repair.

MCO 4790.2

21 Jan 2016

3-15 Enclosure (1)

2. If after acceptance into maintenance, is

found to require repairs that exceed the field LOM.

3. If the item exceeds the MMCT identified

herein, and does not have a valid authorization for extension

and an extension is not anticipated.

4. Supply Support. Supply support

determinations will to be made within 5 days from the date of

requisition. In those instances where supply support cannot be

obtained a supply assistance report (SAR) will be submitted in

accordance with reference (p). Repair parts that are clearly

obtainable, but historically have a slower lead time will be

reported to the supporting Supply Management Unit.

Organizations are authorized to establish and hold DSI in order

to reduce maintenance cycle times. SecRep repair is repetitive

in nature and maintenance managers shall stay abreast of supply

support issues that impact maintenance and must be capable of

making these decisions early in the maintenance cycle.

5. Product Quality Deficiency Program (PQDR)

(SecRep). Often times a customer rejected asset will be

reevaluated by the supporting maintenance section and result in

a PQDR submission. SecRep maintainers have the technical

expertise to observe quality deficiency trends on assets that

are undergoing repairs. Regardless of the scenario, the

supporting maintenance activities will submit a PQDR when

quality deficiency trends are discovered in accordance with

references (v) and (w). RIP managers will be notified on all

PQDR submissions for SecReps. This requirement does not relieve

RIP customers from their responsibility in PQDR submissions.

7. Overflow Maintenance. Overflow maintenance is maintenance

tasks within the unit’s responsibility but beyond its capacity

because of restrictive and/or unusual circumstances and is

consequently performed by another unit or supporting maintenance

activity. The following conditions may prevail:

a. Insufficient maintenance resources; for example,

shortage of technicians or mechanics, shop space or facilities,

maintenance equipment, or inadequate supply support.

b. Cost-effectiveness; for example, instances when it would

be more cost-effective for the supporting maintenance facility

to perform organizational maintenance on supported equipment in

conjunction with or independent of intermediate maintenance.

MCO 4790.2

21 Jan 2016

3-16 Enclosure (1)

Such overflow maintenance will be contingent on the availability

of maintenance resources at the supporting activity and

agreement between the support activity and the supported

organization.

8. Exceptional Maintenance Practices. Exceptional maintenance

practices require continual monitoring in order to ensure these

practices do not become common place. Within the Marine Corps

there are two exceptional maintenance practices; Cannibalization

and Selective Interchange. When reviewing requests for the

conduct of cannibalization and selective interchange each should

be reviewed on a case-by-case basis, and authorized only when

operational availability of the equipment is essential to

mission accomplishment. Cannibalization and selective

interchange are exceptions to established Marine Corps

maintenance practices. These practices increase maintenance

workload, complicates lifecycle planning and serialized

management of materiel, increase the potential for degraded

asset performance and reliability relative to established

standards, and may result in the failure of demand to be

registered within the supply chain. Due to these challenges and

risks, approval of request to conduct will be closely

scrutinized and authority to execute will be granted when it is

absolutely necessary for mission accomplishment. These practices

will be documented, recorded and reported as directed in

reference (x) and outlined below.

a. Cannibalization. The removal of serviceable parts or

components, without replacement, from one unserviceable end item

of equipment in order to install them on another unserviceable

end item of equipment in order to restore equipment to an

operational condition. The purpose of cannibalization is to

restore equipment when those items are required for mission

accomplishment and the required repair parts are not readily

available through the supply chain.

(1) Authority. Marine Corps Logistics Command

(MARCORLOGCOM), as the Marine Corps Ground Asset Manager for